With continuous sampling the measurement data is sent directly to the

computer and Spraytec software for analysis.

.

Timed – as continuous, but the measurement can be requested to stop after

a set amount of time. The stop time is set using the Minutes: and Sec

-

onds: boxes. These boxes only appear when the timed option is selected.

.

Rapid – this is used to measure rapid pulsed spray events, for example nasal

sprays, MDIs or fuel injectors, but can also be used for rapid measurements

of continuous sprays.

The data acquisition rate for the measurement data can be set between

2.5Hz and 2.5kHz. Due to the speed of data acquisition, data obtained

during a rapid measurement is stored by the instrument electronics until

the measurement finishes, then passed to the computer and Spraytec

software for analysis. The Spraytec Measurement Processor downloads the

measurement data from the instrument to the computer.

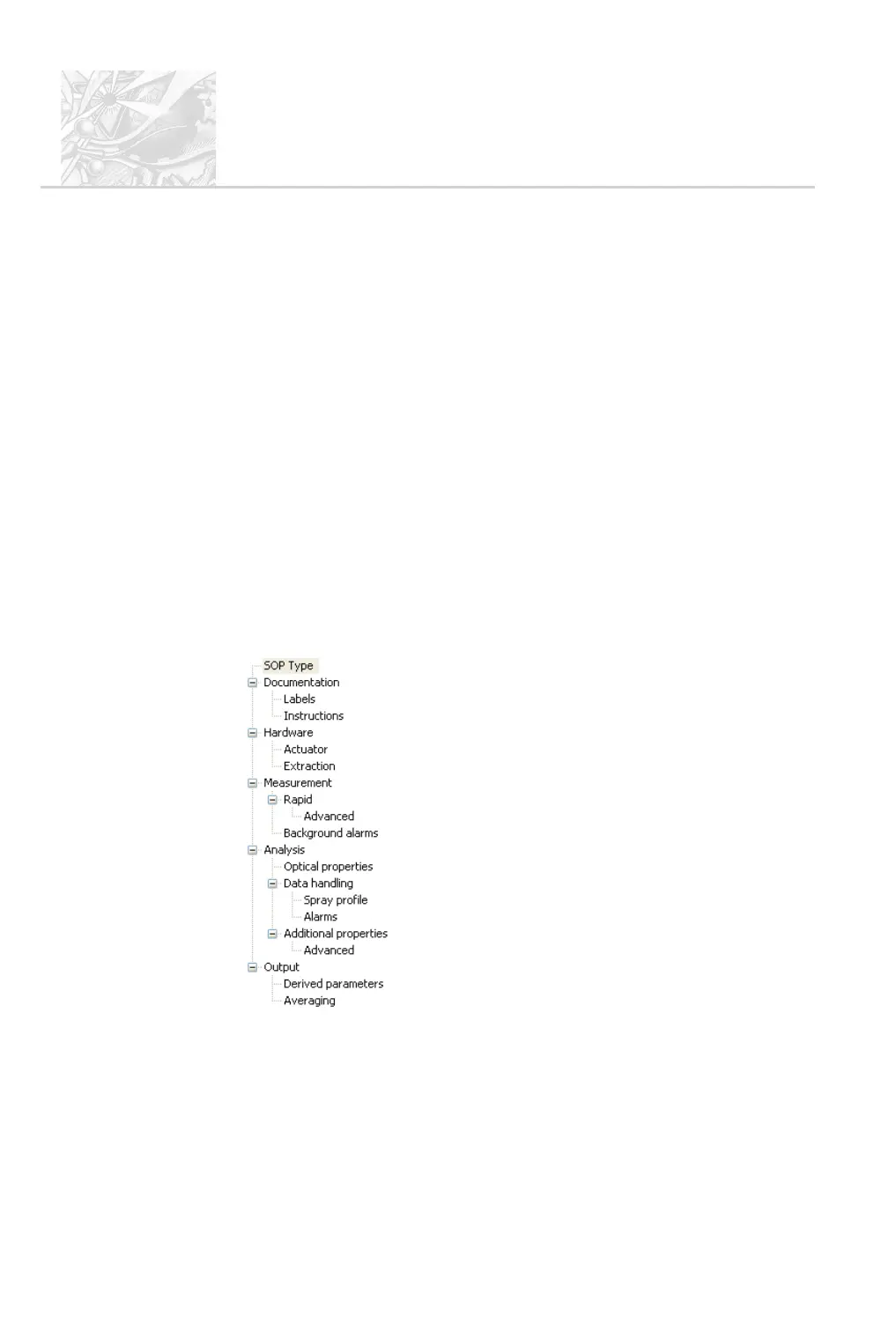

SOP structure

This graphic shows the basic stages in the SOP wizard and the parameters these

are concerned with:

SOP type – hardware, measurement type and lens.

Documentation – spray details, operator instructions.

Hardware – actuator type and details, extraction setup.

Measurement – background, use of output trigger.

Number of events, trigger type.

Filters, optical, electronic and expiry alarms.

Analysis – optical properties of the particle

Detectors to use, plume details

Scattering alarms

Curve fit and correlation

Output – parameters to report, how to average.

When an existing SOP is modified, this tree is shown to allow quick access to any

of the dialogues.

CHAPTER 5

Spraytec

Page 5.6 MAN 0368

Loading...

Loading...