TRANSMISSION AND TORQUE CONVERTER CD3340B/YB4411

7-54

Published 04/07/2015 Control # 569-00

Disassembly

1. Carefully remove piston ring seals (1, Figure 7-74).

NOTE: If the piston ring seals are excessively worn, then

check for burrs or damage on the shaft grooves. If

necessary, remove the burrs with a fine grade

abrasive paper and oil.

2. Remove taper roller bearing (2) using a collet tool and

press.

NOTE: The bearing normally would not be removed unless

it was damaged. If a collet tool is not available, it is

permissible to use a standard bearing puller,

although damage to the bearing cage may occur

which will require a new bearing.

3. At the opposite end, loosen the clutch end bearing (3) by

tapping the assembly on a piece of wood. Remove end

bearing using a puller.

4. Remove friction/counter plates retaining ring (4).

5. Remove pressure end plate (5) and shim (6), if installed.

6. Remove clutch friction plates (7) and counter plates (8).

Keep them together as a set. DO NOT mix the plates

with those of other clutches.

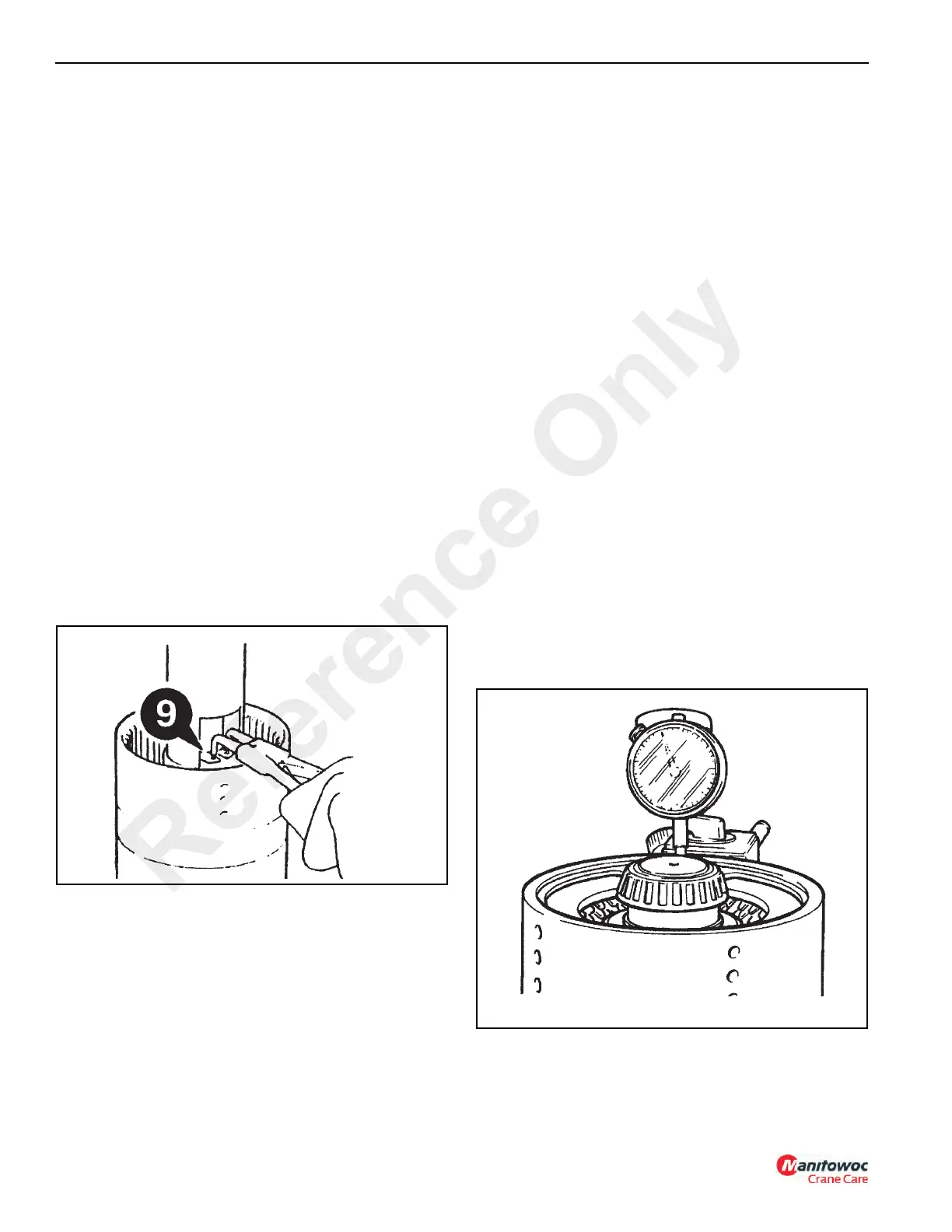

7. Position the clutch assembly in a press along with a

cutaway tube (Figure 7-75). Compress the spring and

remove retaining ring (9).

8. Lift off spring retaining plate (10).

9. Remove spring (11) and oil baffle (12).

10. Knock the clutch on a piece of aluminum (or wood) to

remove piston (13).

NOTE: If the piston does not loosen when the shaft is

knocked on aluminum, then hand pump air down

the shaft oil inlet hole.

11. Remove and discard piston and shaft O-rings (14 and

15).

Assembly

Visually inspect the friction and counter plates:

• Counter plates - light scoring/polishing is permissible,

plates that are flat, worn or heavily marked or scored

must be replaced with a new set.

• Friction Plates - the cross hatching should be clearly

visible, plates that are flat, have friction material damage

or scoring must be replaced with a new set.

DO NOT mix old and new plates. If a plate is damaged/worn

install a complete new set.

Needle roller bearings should slide into position freely, do not

bend or distort the cage to install. If the cage has been

distorted, install new bearings.

1. Install new O-rings (15 and 14). Lubricate with oil and

then press piston (13) fully into bore of hub. Install

pressure end plate (5). Do not install shim (6) at this

stage. Make sure the teeth are not aligned with the

lubrication slots in the housing.

NOTE: A spring disc is not installed in this clutch pack.

2. Install the clutch friction/counter plates retaining ring (4).

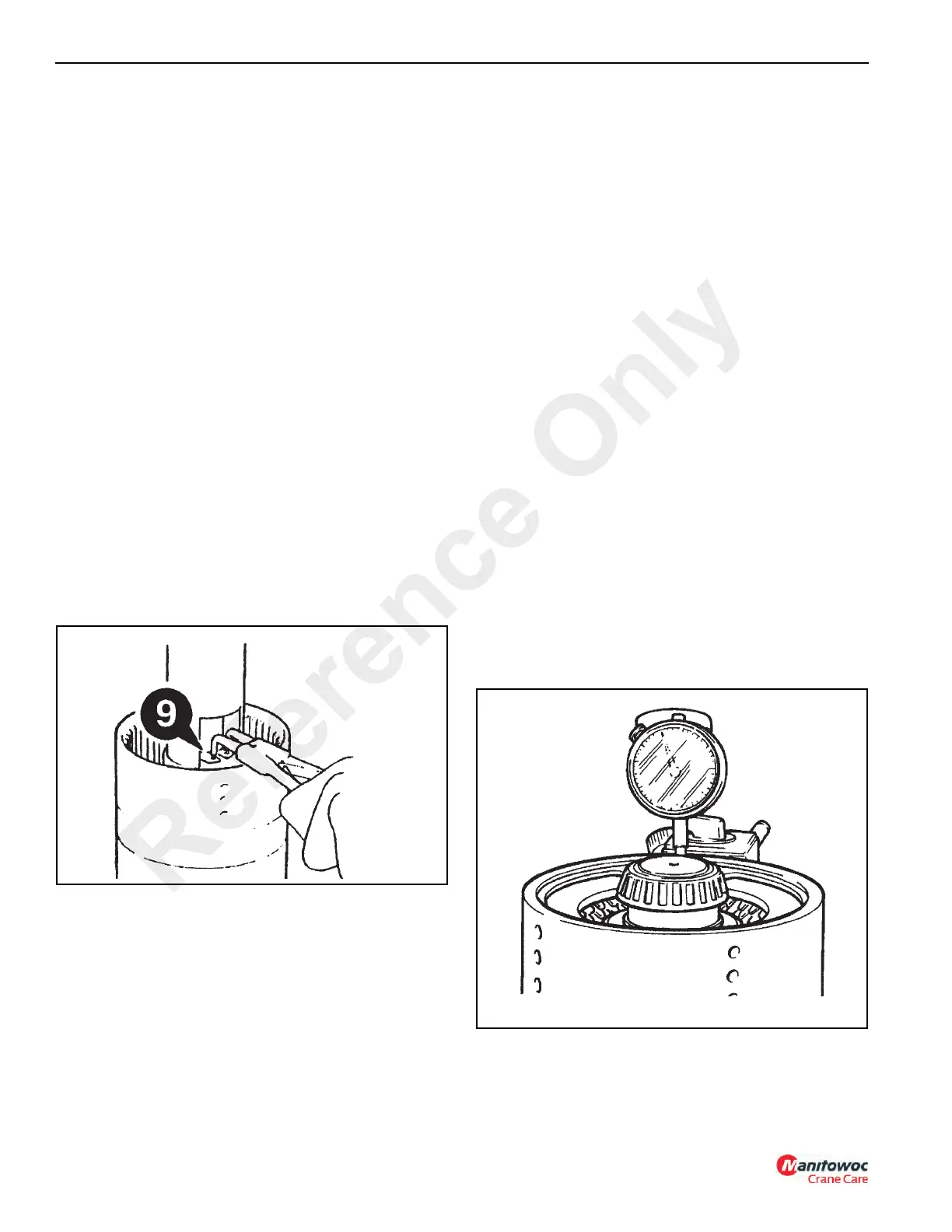

3. Using a dial test indicator as shown in Figure 7-76,

measure the end play of the pressure end plate. End

play should be 0.075 - 0.098 inches (1.9 - 2.5 mm).

To adjust the end play, there is a choice between a 0.23

inch (6.00 mm) or a 0.25 inch (6.5 mm) pressure end

plate (5) with either a shim (6) or extra counter plate (8)

between retaining ring (9) and pressure end plate (5).

4. Coat the clutch end bearings (3 and 2) with a Lithium

Base, E.P. No. 2 bearing grease and press the bearings

onto the shaft.

5. Install piston ring seal (1). See (PTFE) Piston Ring Seal

Installation Procedure, page 7-58.

Reference Only

Loading...

Loading...