BRAKE SYSTEM CD3340B/YB4411

9-6

Published 04/07/2015 Control # 569-00

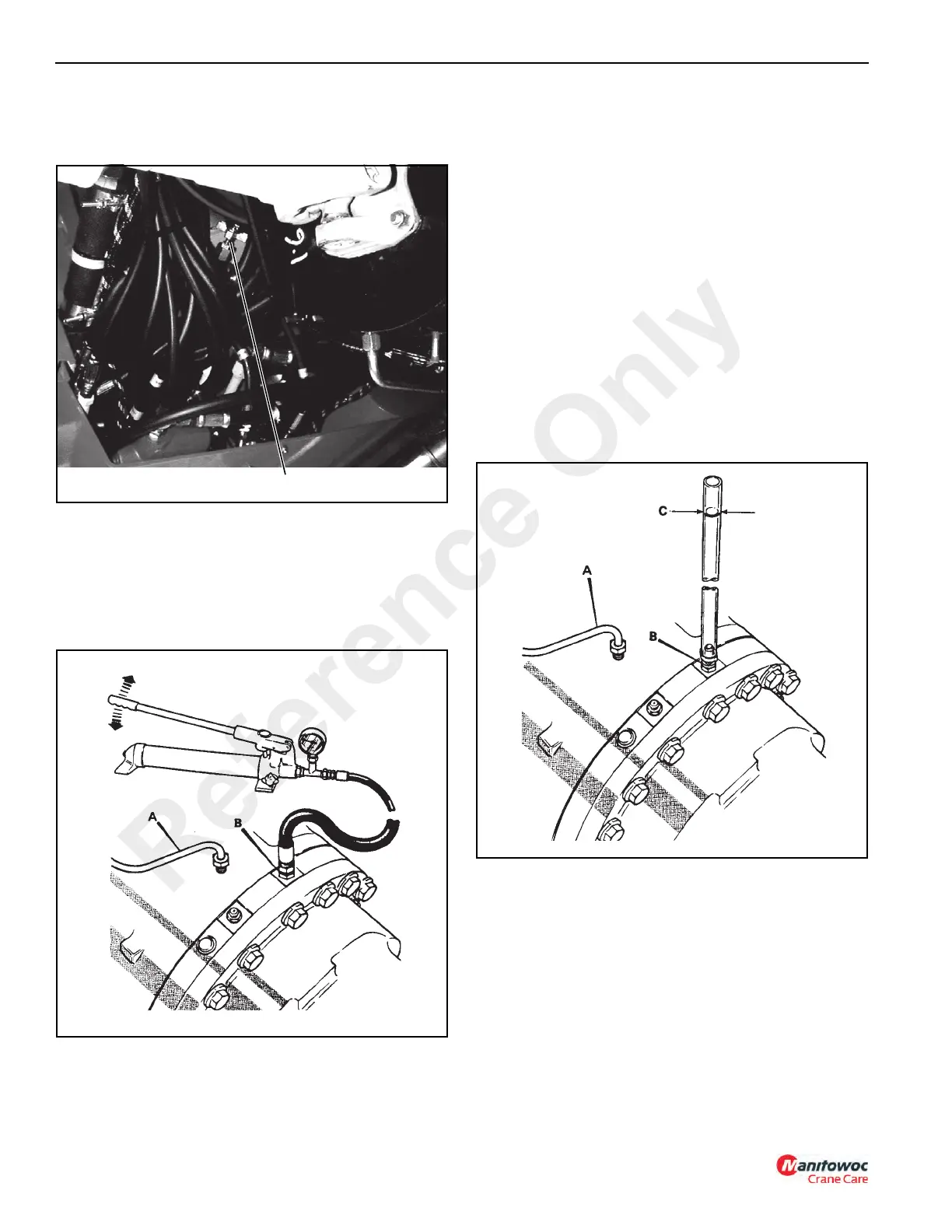

1. With the engine shutoff and the parking brake engaged,

close the accumulator needle valve (Figure 9-7) to shut

off hydraulic pressure to the service brakes.

2. Actuate the brake foot pedal until no resistance is felt

and the system pressure has been released.

NOTE: Do not disconnect any lines until the brake circuit

pressure has been released.

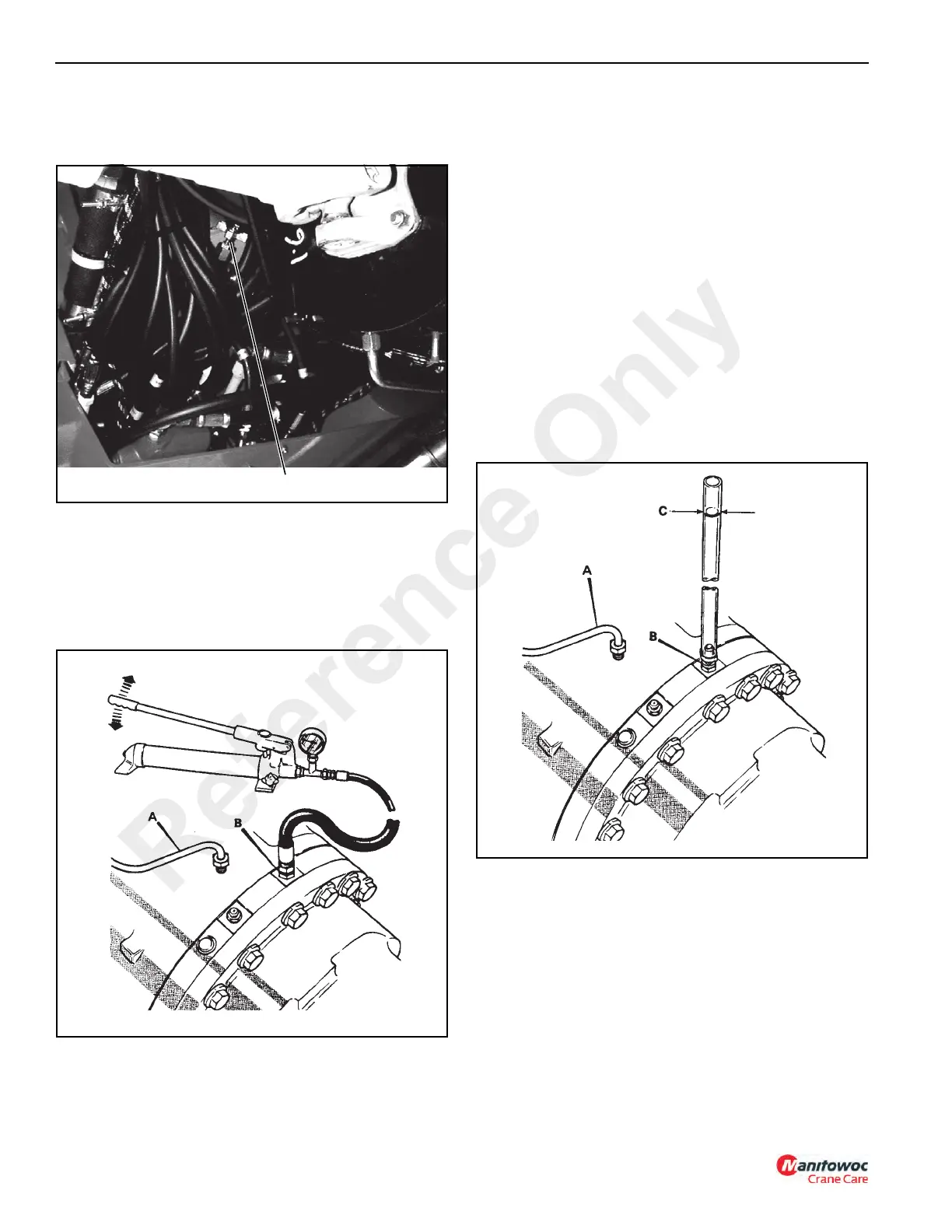

3. Remove and cap the brake piston feed line (A,

Figure 9-8).

4. To check for severe piston seal damage:

a. Fill the housing of hand pump with recommended

lubricant. See Maintenance, page 5-1.

b. Install the hand pump fitted with a 0 to 6890 kPa (0

to 1000 psi) pressure gauge to port (B, Figure 9-8).

NOTE: The hand pump MUST be filled with recommended

oil (see Maintenance, page 5-1). System pressure

is 3790 kPa (550 psi). DO NOT exceed 4134 kPa

(600 psi).

c. Use the hand pump to generate a pressure in the

brake piston housing.

d. If the pressure falls off rapidly, or if no pressure

reading can be obtained, the seals are severely

damaged and must be replaced.

5. If pressure falls off slowly, the piston seals may have

small cuts or nicks. To verify for small cuts or nicks in the

piston seals perform the following test:

a. Install an adapter fitted with a piece of clear tube

(approximately 120 mm (4.75 in) long to the brake

piston port (B, Figure 9-9).

NOTE: The tube must be kept vertical during the test. Use

tape to attach the tube to the side of machine.

b. Fill the tube with recommended oil (see

Maintenance, page 5-1) three quarters full.

c. Using a suitable pen, mark the level line (C) of the

fluid in the tube.

d. After approximately 1/2 hour, check if the level has

dropped below the original marked line. If it has then

check the brake piston seals for slight nicks, cuts or

general wear.

6. Repeat steps 3 through 5 for the opposite brake piston

seals.

FIGURE 9-7

P0718

Accumulator Needle Valve

Reference Only

Loading...

Loading...