STEERING SYSTEM CD3340B/YB4411

10-14

Published 04/07/2015 Control # 569-00

14. Remove seal (4, Figure 10-9) from housing (8).

15. Remove set screw (25).

16. Screw a No. 10-24 machine screw into the end of check

ball seat (23). Then by pulling on the screw with a pliers,

lift the seat out of the housing.

17. Remove two seals (22 and 24) from the check ball seat.

18. Tip the housing to remove check ball (21) and check ball

retainer (20).

Inspection

Check all mating surfaces. Replace any parts that have

scratches or burrs that could cause leakage or binding.

Clean all metal parts in a clean solvent. Blow dry with air. Do

not wipe dry with a cloth or paper towel, because lint or other

matter can get into the hydraulic system and cause damage.

Do not use a coarse grit emory cloth or try to file or grind any

parts.

Replace all seals when assembling the unit. Lubricate all

seals with clean petroleum jelly before assembling. DO NOT

use excessive lubricant on seals for the meter section.

Assembly

1. Use a needle nose pliers to lower check ball retainer (20,

Figure 10-9) into the check valve hole in housing (8).

2. Install check ball (21) into housing (8).

3. Lubricate seals (22 and 24) and install them on check

ball seat (23).

4. Lubricate the check ball seat and seals thoroughly

before installing into the housing. When installing the

seat do not twist or damage the seals. Install the check

ball seat into housing, insert open end first. Push the

check ball seat to the shoulder of the hole.

5. Install set screw (25) and tighten to a torque of 11.3 Nm

(100 lb-in). To prevent interference, make sure the top of

the set screw is slightly below the housing mounting

surface.

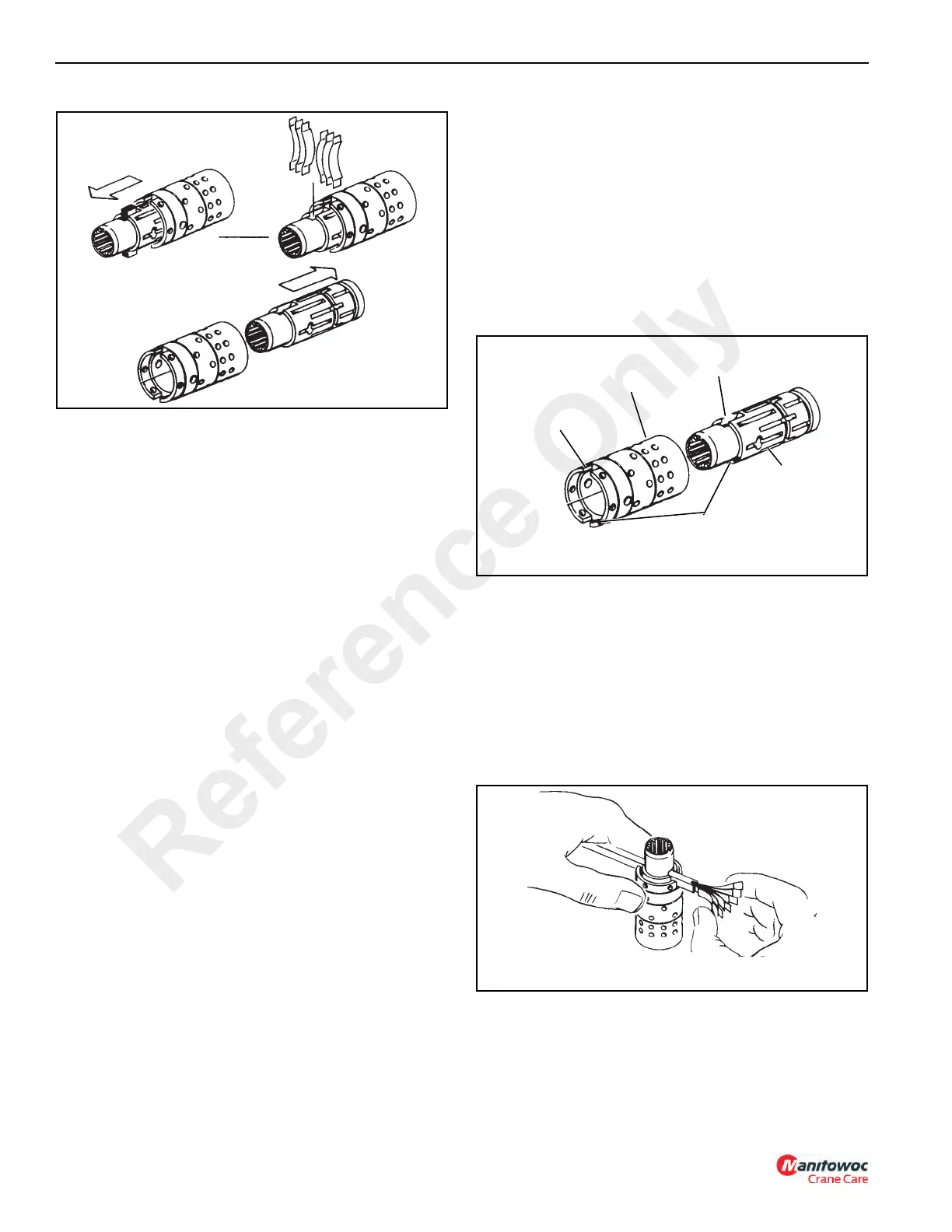

6. Lubricate the spool (12) and sleeve (9). Install spool (12)

and sleeve (9) carefully so that the spring slots

(Figure 10-15) line up at the same end. Rotate spool

(12, Figure 10-9) while sliding the parts together. Some

spools and sleeve sets have identification marks, align

these marks as shown in Figure 10-15. Test for free

rotation. The spool should rotate smoothly in the sleeve

with finger tip force applied at splined end.

7. Bring spring slots of both parts in line and stand parts on

end on the work bench (Figure 10-16). Insert special

spring installation tool through the spring slots of both

parts.

Position centering springs (in 2 sets of 3 each) on bench

so that the extended edge is down and arched center

section is together. In this position, insert one end of the

entire spring set (all six) into the spring installation tool,

as shown in Figure 10-16, with spring notches facing the

sleeve.

8. Compress the extended end of the centering spring set

and push into the spool and sleeve assembly,

withdrawing the installation tool at the same time.

9. Center the spring set in the parts so they push down

evenly and flush with the outer surface of the sleeve.

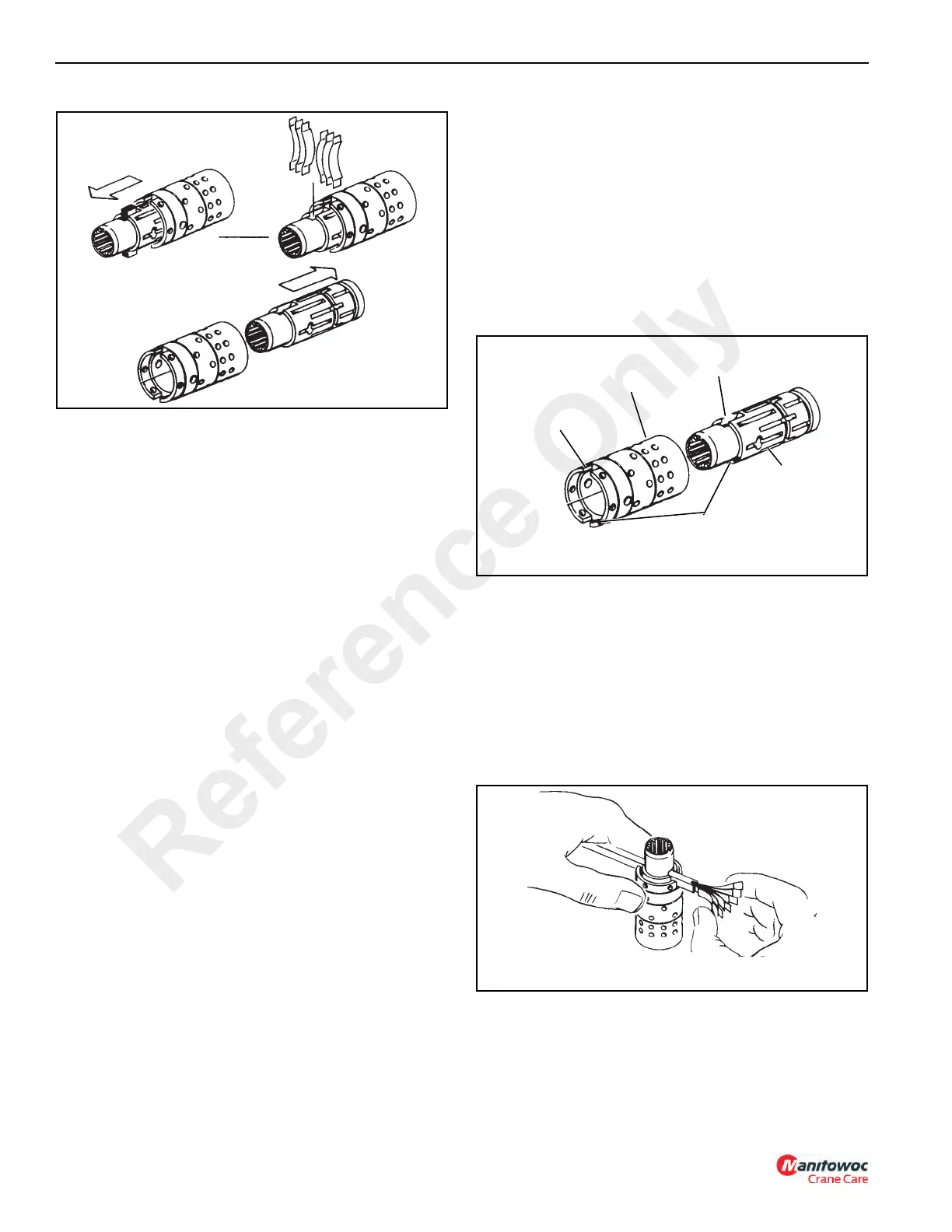

FIGURE 10-15

a0332

Spring

Slot

Control

Sleeve

Spring

Slot

Identification

Marks

Control

Spool

Reference Only

Loading...

Loading...