GROVE 10-15

CD3340B/YB4411 STEERING SYSTEM

Published 04/07/2015 Control # 569-00

10. Insert pin (11, Figure 10-9) through the spool and sleeve

assembly until the pin becomes flush at both sides of the

sleeve.

11. Lubricate the spool and sleeve assembly and position

the assembly so that the splined end of the spool enters

the meter end of housing (8, Figure 10-9). See

Figure 10-17.

NOTE: Be extremely careful that the parts do not tilt out of

position while inserting. Push parts gently into

place with a slight rotation action; keep the pin

horizontal. Bring the spool assembly entirely within

the housing bore until the parts are flush at the

meter end of the housing. Do not pull the spool and

meter assembly beyond this point to prevent the

cross pin from dropping into the discharge groove

of the housing. With the spool assembly in this

flush position, check for free rotation within the

housing by turning with a light finger tip force at the

splined end.

12. Place the housing on a clean, lint free cloth. Install seal

(4, Figure 10-9) into housing (8).

13. Install needle bearing kit (6).

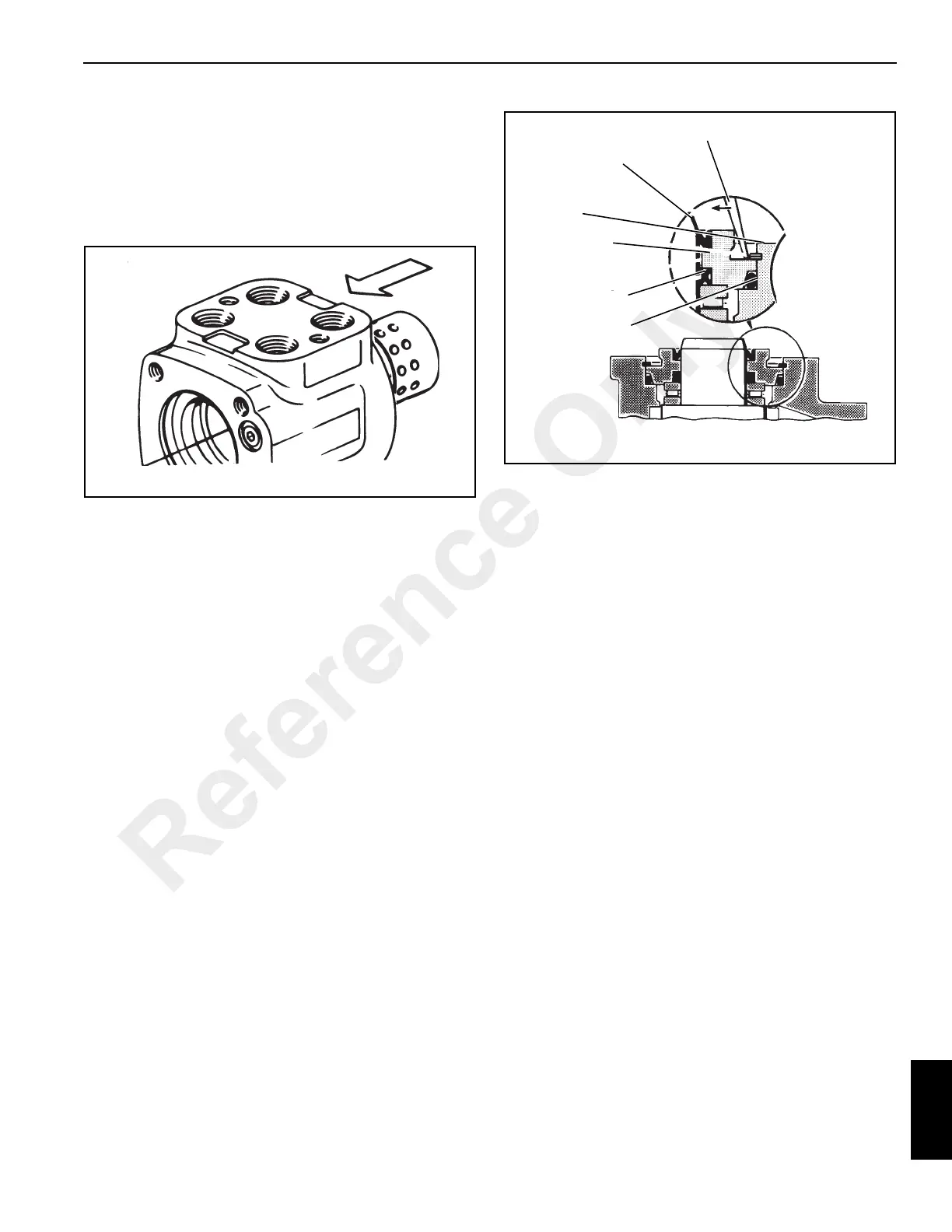

14. Install dust seal (1) into seal gland bushing (3). Flat or

smooth side of the dust seal must face down towards the

bushing. See Figure 10-18.

15. Install quad ring seal (5, Figure 10-9) into seal gland

bushing (3). Smooth seal in place with your finger. Do

not use any seal that falls freely into the pocket of the

bushing. See Figure 10-18.

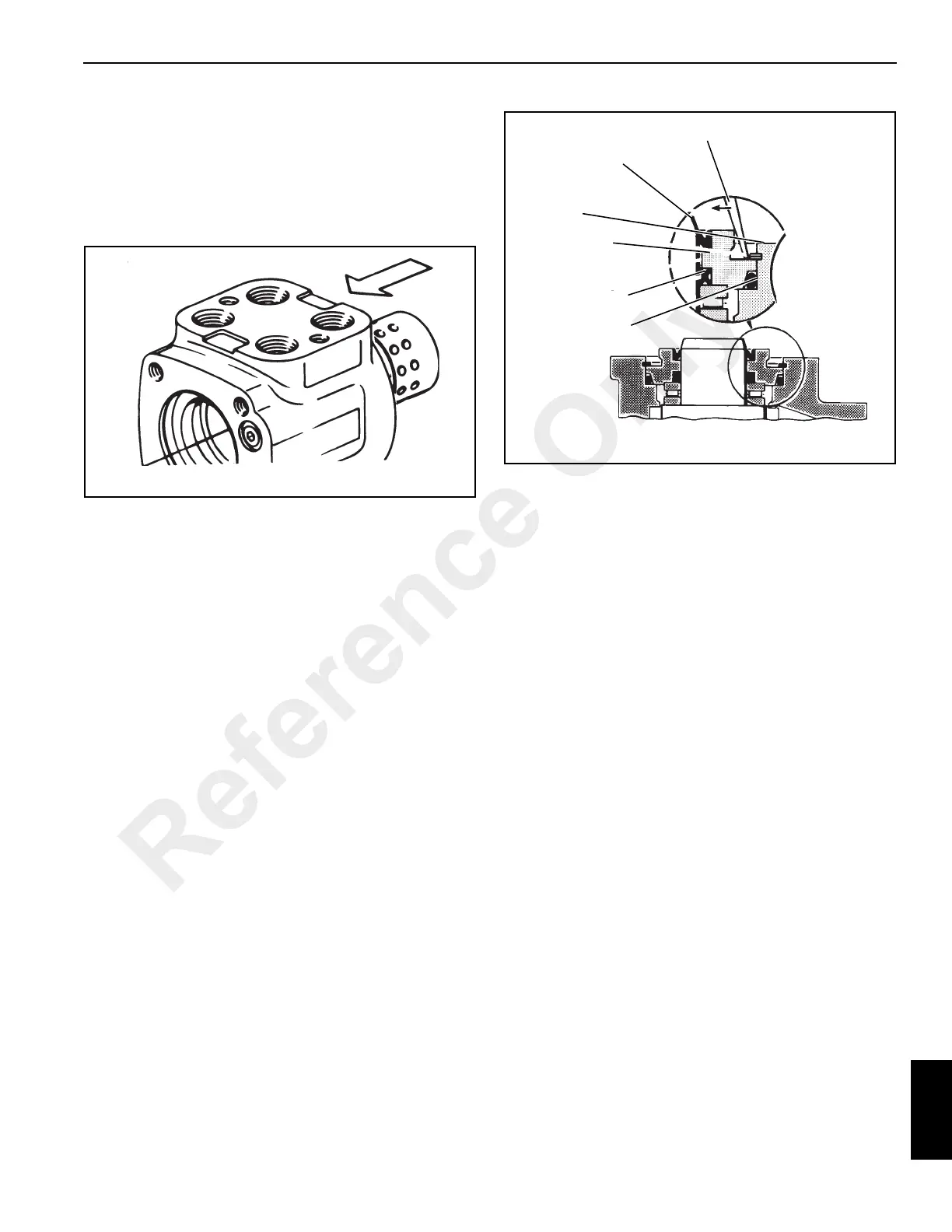

16. Install seal gland bushing (3, Figure 10-9) over the spool

end with a twisting motion. Tap the bushing in place with

a rubber hammer. Make sure the bushing is flush

against the bearing race.

17. Install retaining ring (2, Figure 10-9) in the housing (see

Figure 10-18). After installing the retainer ring, tap on

ring end or pry with a screwdriver around entire

circumference of the ring to properly seat the ring in the

groove.

18. Clamp housing (8, Figure 10-9) in a vise. Clamp lightly

on edges of mounting area. Do not over tighten the vise

jaws.

NOTE: Check to ensure that the spool and sleeve

assembly are flush or slightly below the mounting

surface.

NOTE: Clean the upper surface of the housing by wiping

with the palm of your hand. Clean each of the flat

surfaces of the meter section parts in a similar way

when ready for assembly. DO NOT USE cloth or

paper to clean the surfaces.

19. Install seal (13) into grove in housing (8). Install spacer

plate (14). Align bolt holes in spacer plate with tapped

holes in the housing.

20. Rotate the spool and sleeve assembly until pin (11) is

parallel with the port face (see Figure 10-19). Install

drive (15, Figure 10-9), Make sure you engage the drive

with pin (11). To ensure proper alignment, mark the drive

as shown in Figure 10-20, Ref. B. Note relationship

FIGURE 10-18

a0337

Screwdriver

Dust Seal

Retaining Ring

Seal

Gland Bushing

Quad Ring Seal

Seal

Reference Only

Loading...

Loading...