GROVE 4-45

CD3340B/YB4411 HYDRAULIC SYSTEM

Published 04/07/2015 Control # 569-00

1. Put the ports of the cylinder down to drain the oil from

the cylinder.

2. Fasten the base of the cylinder in a vise with soft jaws.

Place a support under the rod so the cylinder is level.

3. Use a spanner wrench to loosen and remove the head

gland. Slide the head gland forward on the cylinder rod.

4. Pull the cylinder rod and piston straight out of the

cylinder tube. If the cylinder and piston are hard to

remove, install the head gland back into the cylinder and

apply shop air to the base port to push the piston out to

the head gland.

5. Fasten the eye of the rod in a vise with soft jaws. Put a

support under the opposite end of the rod to hold the rod

level. Use care not to cause damage to the chrome

surface of the rod.

6. The piston is fastened to the rod either by internal

threads or with a locking nut. To remove the piston:

a. On pistons with internal threads, remove the set

screw from the piston. Use a spanner wrench to

loosen and remove the piston.

b. On pistons which are fastened with a locking nut,

use a socket wrench to loosen the nut.

7. Remove and discard the seals and wear rings from the

piston.

8. Remove and discard all seals, backup rings, wear rings,

etc. from the head gland.

Inspection

Wash the parts in a suitable solvent. Use compressed air to

remove all residue and dry.

Check the bore of the cylinder tube for damage or distortion.

Move the piston through the full length of the cylinder and

check the clearance between the piston and the bore of the

cylinder. If there is damage or distortion, replace the cylinder

tube.

Look for damage to the chrome surface of the rod. The rod

must be smooth and straight. A bent rod indicates possible

loss of strength in the rod and replacement is necessary. If

the chrome surface has damage, completely remove the old

chrome and apply new chrome 0.03 mm (0.001 in) thick.

Assembly

1. Install new rings, rod wiper and seals on the head gland.

See cylinder illustrations for location and correct

installation.

2. Apply hydraulic oil to the rod and slide the assembled

head gland on the rod.

3. Assemble the rings and seals on the piston.

4. Be sure O-ring is installed between the piston and the

rod. Fasten the piston to the rod with locking nut and

tighten to the specified torque. On pistons with internal

threads, apply Loctite 243 to the threads and screw

piston onto cylinder rod and torque in place.

5. Apply hydraulic oil to the bore of cylinder and the rings

on the piston. Carefully slide the piston and rod into the

cylinder tube. Keep the rod straight during installation.

Use care not to damage the piston rings when you move

the piston past the threads in the bore of the cylinder

tube.

6. Slide the head gland into the cylinder tube and tighten to

the specified torque. See illustrations. If equipped, install

the set screw to secure the gland head in the cylinder.

Test

1. Fill the cylinder with clean hydraulic oil. Test to pressure

in both directions as directed in steps 2 through 5.

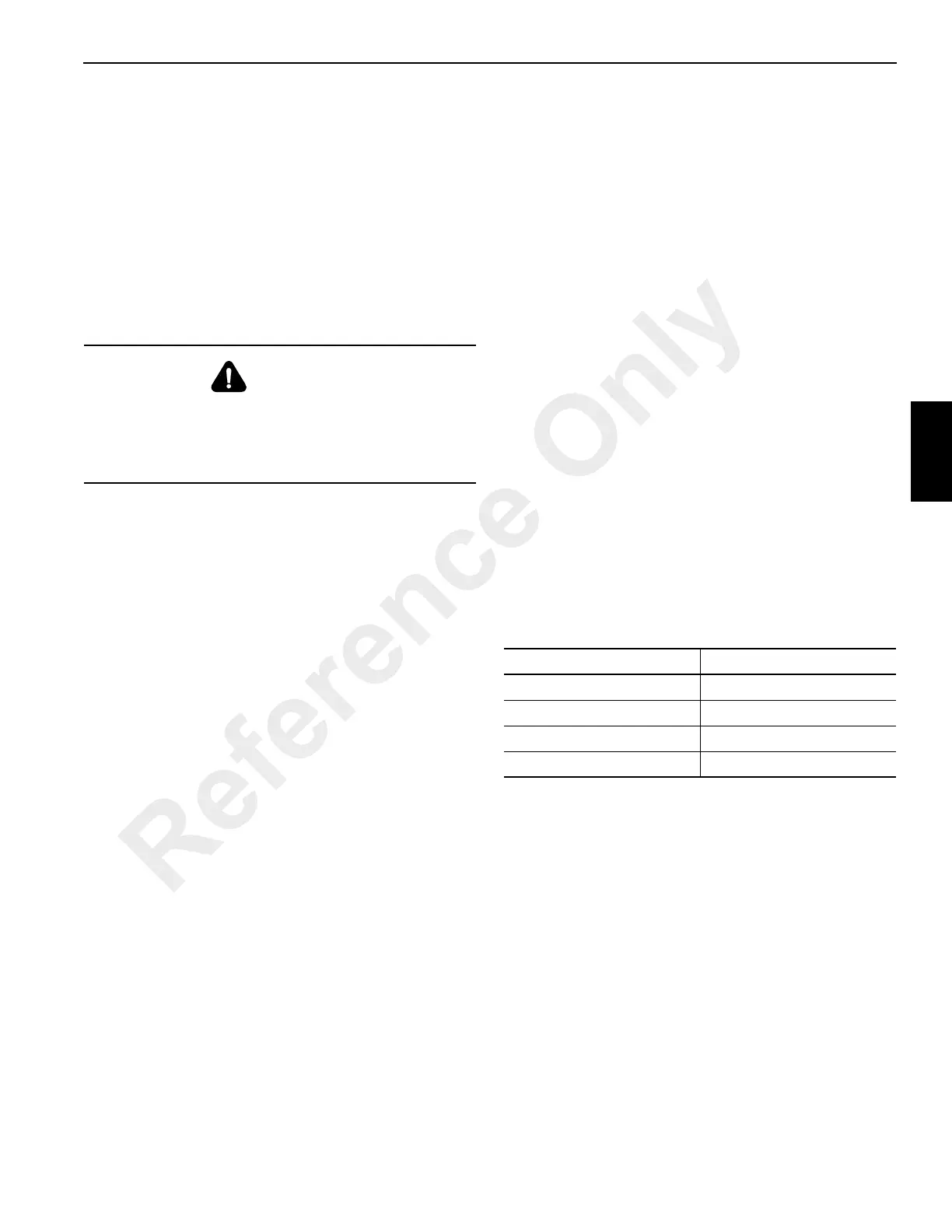

Table 4-10

2. Move the cylinder rod through two complete strokes at

5510 kPa (800 psi) to remove air from the cylinder. Look

for external leaks. If the pressure difference between

cylinder ports is more than 689 kPa (100 psi) during the

second stroke, the cylinder assembly is not acceptable.

Disassemble and inspect for foreign materials or wrong

assembly.

3. Wipe the cylinder rod clean, then move the cylinder

through four complete strokes at 5510 kPa (800 psi), but

do not permit the cylinder to hit bottom on each stroke.

After four strokes, extend the cylinder rod just far

enough to see how much oil has collected during the

four strokes. Inspect the cylinder rod for indication of rod

seal leakage. A thin layer of oil on the cylinder rod is

normal.

4. Fully retract the cylinder rod. Keep the base port open.

Apply test pressure (Table 4-10) to the rod port. Hold this

WARNING

Flying Parts Hazard!

If air or hydraulic pressure is used to force out the piston

assembly, ensure that the head gland is securely installed

in the cylinder tube.

Cylinder Test Pressure

Lift 34474 kPa (5000 psi)

Telescope 34474 kPa (5000 psi)

Horizontal Outrigger 24131 kPa (3500 psi)

Vertical Outrigger 24131 kPa (3500 psi)

Reference Only

Loading...

Loading...