HYDRAULIC SYSTEM TMS700E SERVICE MANUAL

2-56 Published 01-29-2015, Control # 512-01

Assembly

NOTE: Lubricate seals and rings with clean hydraulic oil.

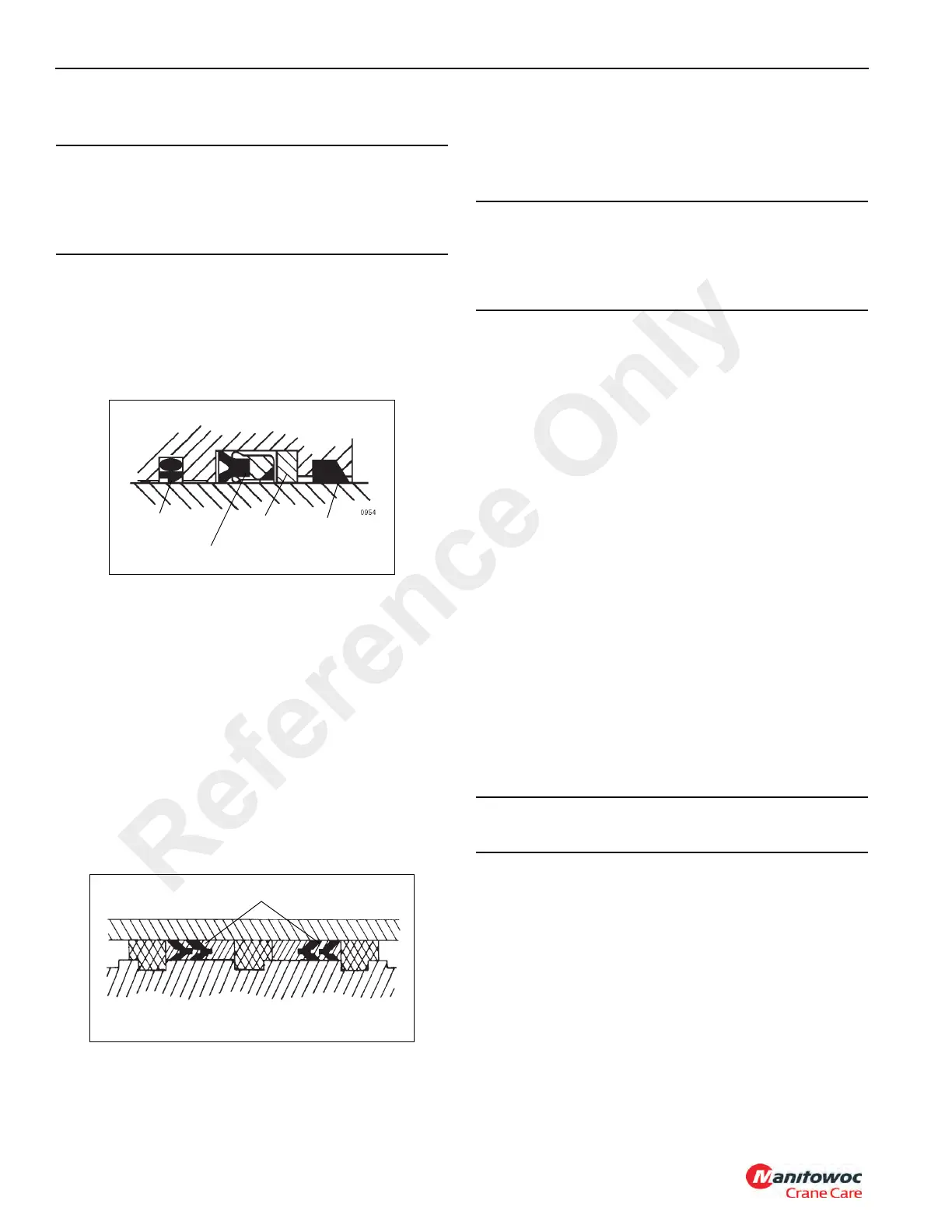

1. Install the backup ring and wiper ring into the retaining

ring (Figure 2-41).

2. Install head retainer ring on rod.

3. Install two new threaded inserts into head.

4. Install the replacement wear rings, buffer seal and deep

Z rod seal in the inside of the head (Figure 2-40). Make

sure the buffer seal’s step is closer to the deep Z rod

seal. Make sure the deep Z rod seal’s rim groove is

closer to the buffer seal.

5. Install the replacement O-ring and the backup ring on

the outside of the head.

6. Install the replacement O-ring and backup rings in the

inside of the piston.

7. Lubricate the rod with clean hydraulic oil.

8. Slide the head, onto the rod.

9. Screw the piston onto the rod tightly. Secure the piston

with the set screw.

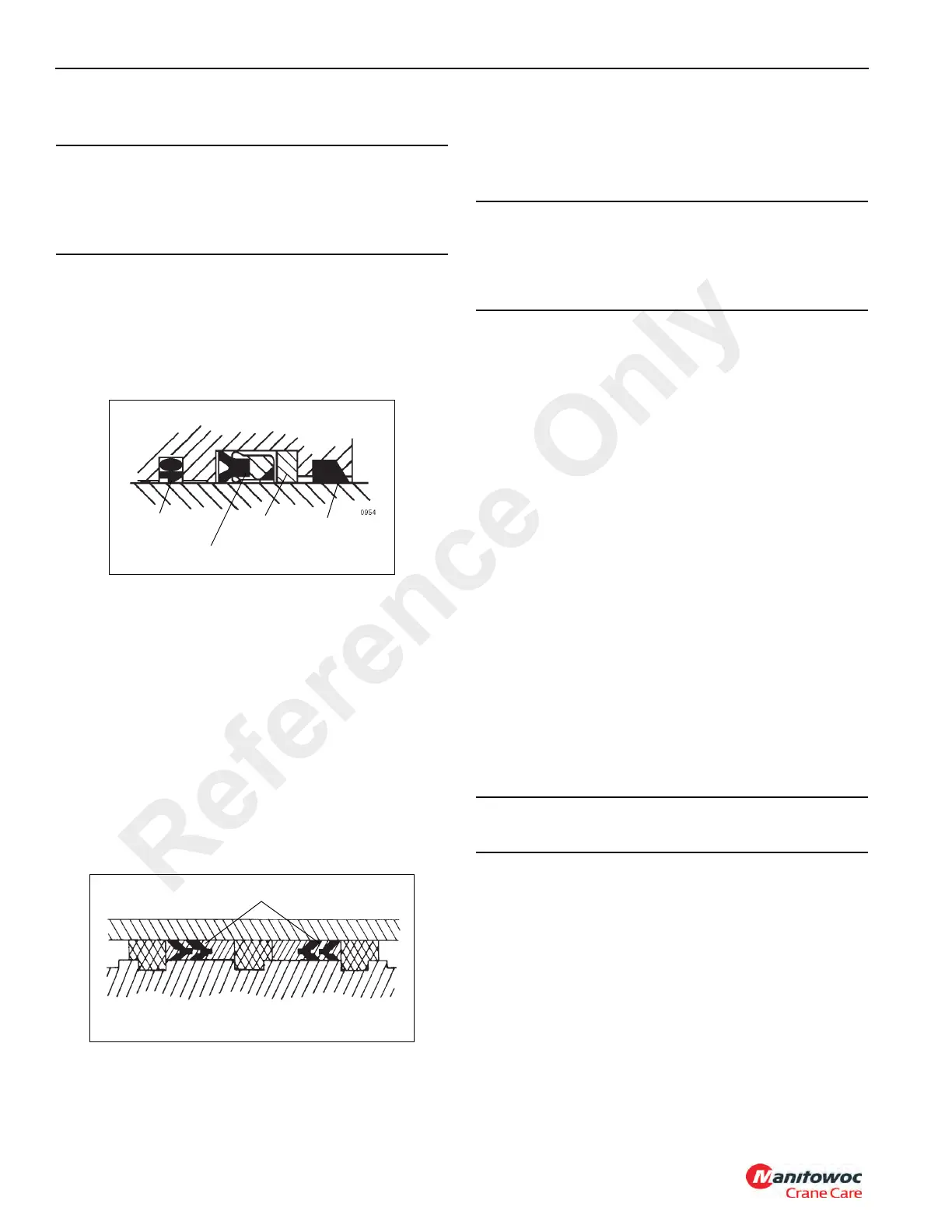

10. Install the replacement hydrolock seals on the outside of

the piston. Make sure the “vees” on the two hydrolock

seals point at each other.

11. Lubricate all parts freely with clean hydraulic oil.

12. Remove the cover from the barrel. Insert the rod and

attached parts into the barrel with a slight twisting

motion.

13. Install new gasket material to the cylinder head retainer

ring flange as follows.

a. Clean the barrel and retainer ring with Loctite

cleaning solvent 7070 or similar non- chlorinated

solvent.

b. Apply a light coating of Loctite primer N7649 to both

surfaces. Allow primer to dry for one to two minutes.

Primer must be dry. Mating of parts should occur

within five minutes.

c. Apply gasket material Loctite Master Gasket 518 to

one surface. Partial cure is obtained in four hours,

with full cure in 48 hours.

14. Screw the head retainer ring into the barrel and align

holes in retainer ring with holes in head. Secure the

head retainer ring to the head with two socket head

capscrews. Torque screws to 60 to 65 Nm (44 to 48 lb-

ft).

15. Using a spanner wrench or chain wrench, continue to

screw the retainer ring/head into place in the barrel.

16. Position the holding valve on the cylinder barrel and

secure with four screws and washers.

17. Connect the tubing to the holding valve.

18. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder rod side at 241 bar (3500

psi). Test the cylinder piston side at 413 bar (6000 psi).

Check for proper operation and any leakage. Make

repairs as needed.

19. After successful pressure testing, retorque screws

holding retainer ring to head to 60 to 65 Nm (44 to 48 lb-

ft).

CAUTION

When installing new seals and rings, avoid stretching

seals or scratching the grooved or gland surfaces. Make

sure parts are clean before and during assembly. Make

sure seals and rings are installed in the proper order.

Wiper Ring

Deep Z Rod Seal

Buffer Seal

FIGURE 2-40

Backup

Ring

Hydrolock Piston Seals

FIGURE 2-41

CAUTION

Exercise extreme care when handling the rods. Damage

to the rod surface may cause unnecessary maintenance

and expense. Also, take care to avoid damaging grooved

or gland surfaces, rings or seals during rod insertion.

CAUTION

Do not use air pressure to cycle or pressurize the cylinder.

Reference Only

Loading...

Loading...