Repair Comet Executive Gas

7-28

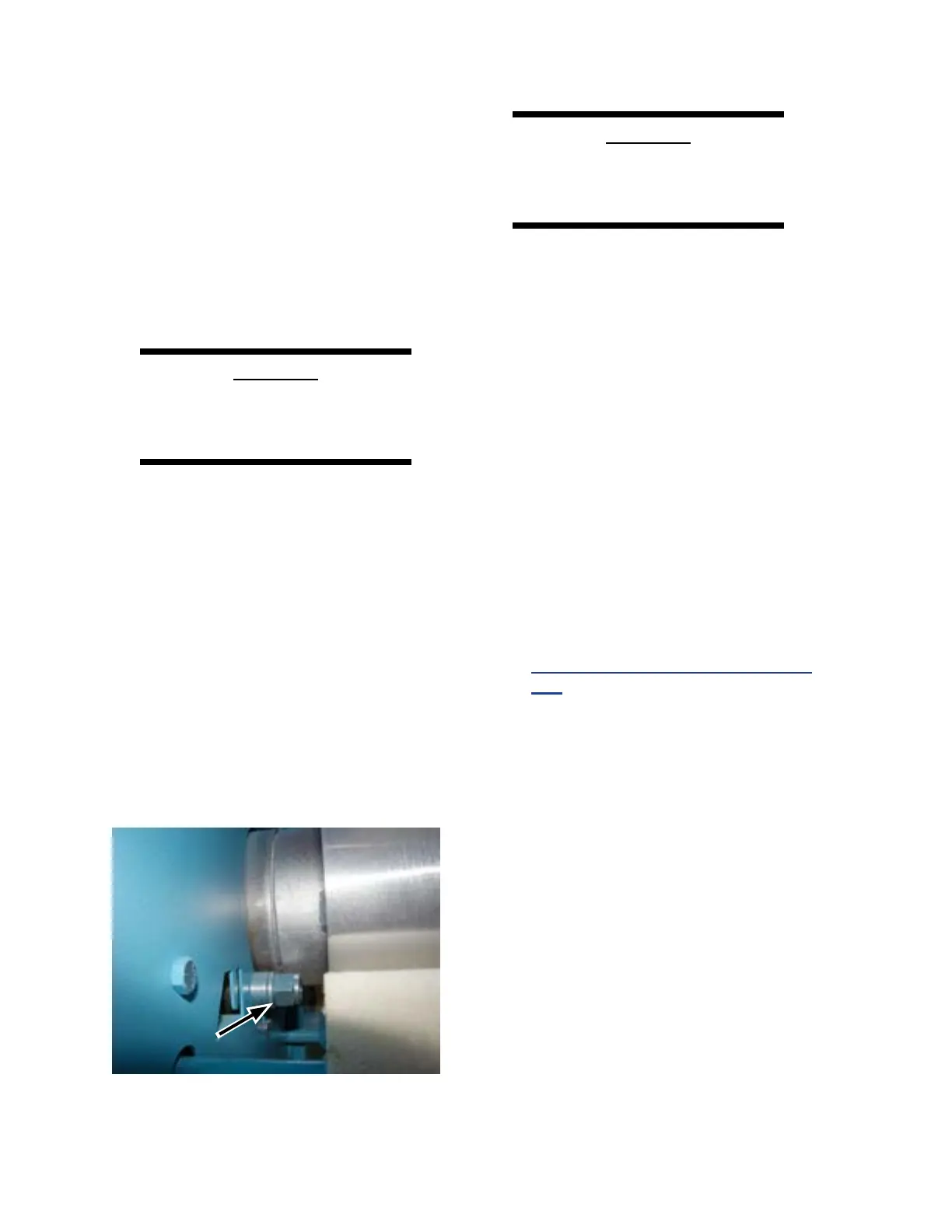

4. Remove the cam follower bearings (Figure

7-24, B) by unscrewing the nuts located

on the inside of the left endframe (Figure

7-25). Carefully examine their condition

and determine if replacement is appropri-

ate.

5. There are 3 or 4 1/4” roll pins located

around the body of the hardened ring

(Figure 7-24, C). Use a punch to drive all

of these out.

CAUTION

Be careful not to damage the

surface of the trunnion when

removing the old ring.

6. If possible, use a suitable punch to drive

o the old ring. Depending on the condi-

tion of the ring, it may have to be cut o

instead.

7. If it is necessary to cut o the old ring,

use a saw with a steel cutting blade to

cut a deep notch in the ring and then use

a cold chisel to force the ring to expand

for removal.

8. Use a scraper or coarse sandpaper to clean

any rust or scale from the surface of the

trunnion and lightly oil the trunnion.

CAUTION

Do not heat the hardened

ring to make it easier

to install.

9. Drive on the new hardened ring using a

block of hard wood as a cushion to pre-

vent damage. Do not strike the new ring

directly with a hammer. Drive on four

alternating points to avoid cocking or

jamming the ring.

10. Drill new holes for the roll pins through

the holes in the hardened wear ring and

into the trunnion.

11. Install new roll pins.

12. Re-install the cam follower bearings by

reversing Step 4.

13. Slowly and carefully remove the wooden

wedges. Use the jack to lower the ironing

cylinder onto the cam follower bearings.

14. Re-install the burner system; refer to

Burner Removal/Replacement on page

7-29.

Figure 7-25: Cam follower bearing nut inside the

left endframe.

Loading...

Loading...