Comet Executive Gas Installation

2-21

Follow the procedure below for the type of gas

being used—natural gas, liqueed petroleum gas,

or manufactured gas.

For Natural Gas:

Perform only when the unit is OFF

with power disconnected and COOL.

1. Turn power OFF at the main disconnect

switch.

WARNING

Do not adjust or test gas

components unless you are

qualied to do so.

2. Connect a U-tube or other water column

manometer upstream of the gas connec-

tion, and measure the static gas pressure.

3. If the pressure is:

• Less than 5” (1.25 kPa): Burner may

not work reliably. Correct the gas pres-

sure before proceeding.

• 5” - 11” (1.25 - 2.75 kPa): Proper op-

erating range.

• More than 11” (2.75 kPa): This is a

high pressure gas supply. Installation

of an additional regulator is necessary:

1) The additional regulator must be

mounted according to the manu-

facturer’s specications.

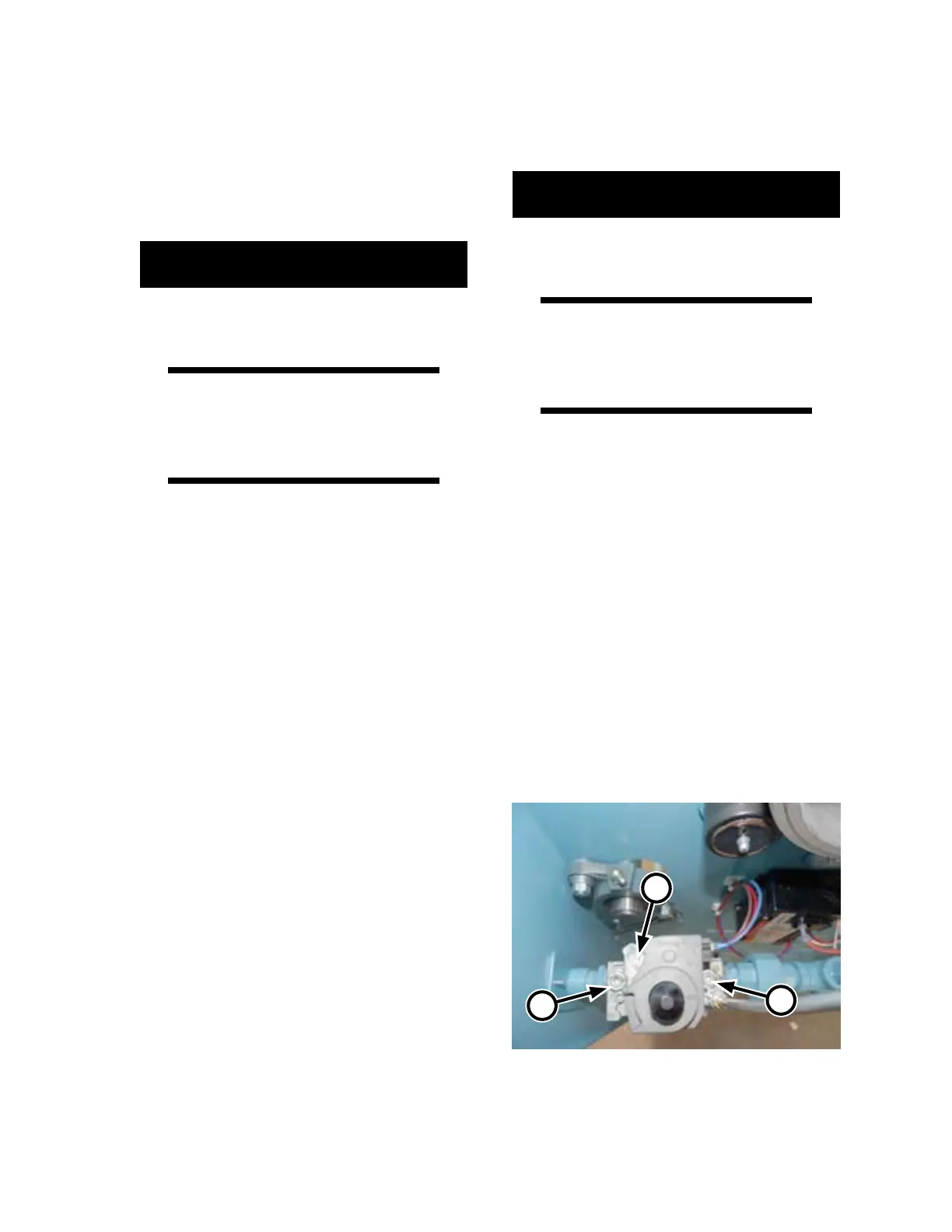

2) Open the left endframe door and

measure the incoming gas pressure

to gas valve (Figure 2-20) to make

sure it is now in the proper range

(connect the manometer to the “in”

port on the gas valve, A).

3) When replacing the plug, use pipe

thread compound to avoid leaks.

Teon tape is not recommended.

For Liqueed Petroleum Gas

(Propane, Butane):

Perform only when the unit is OFF

with power disconnected and COOL.

1. Turn power OFF at the main disconnect

switch.

WARNING

Do not adjust or test gas

components unless you are

qualied to do so.

2. Connect a U-tube or other water column

manometer upstream of the gas connec-

tion, and measure the static gas pressure.

3. If the pressure is:

• Less than 11” (2.75 kPa): Burner may

not work reliably. Correct the gas pres-

sure before proceeding.

• 11” - 12” (2.75 - 3.0 kPa): Proper op-

erating range.

A

B

C

Figure 2-20: Make sure to check gas operating

pressure (B) as well as upstream

pressure (A).

Loading...

Loading...