FUEL PUMP

90-855347R1 JANUARY 1999 Page 3A-3

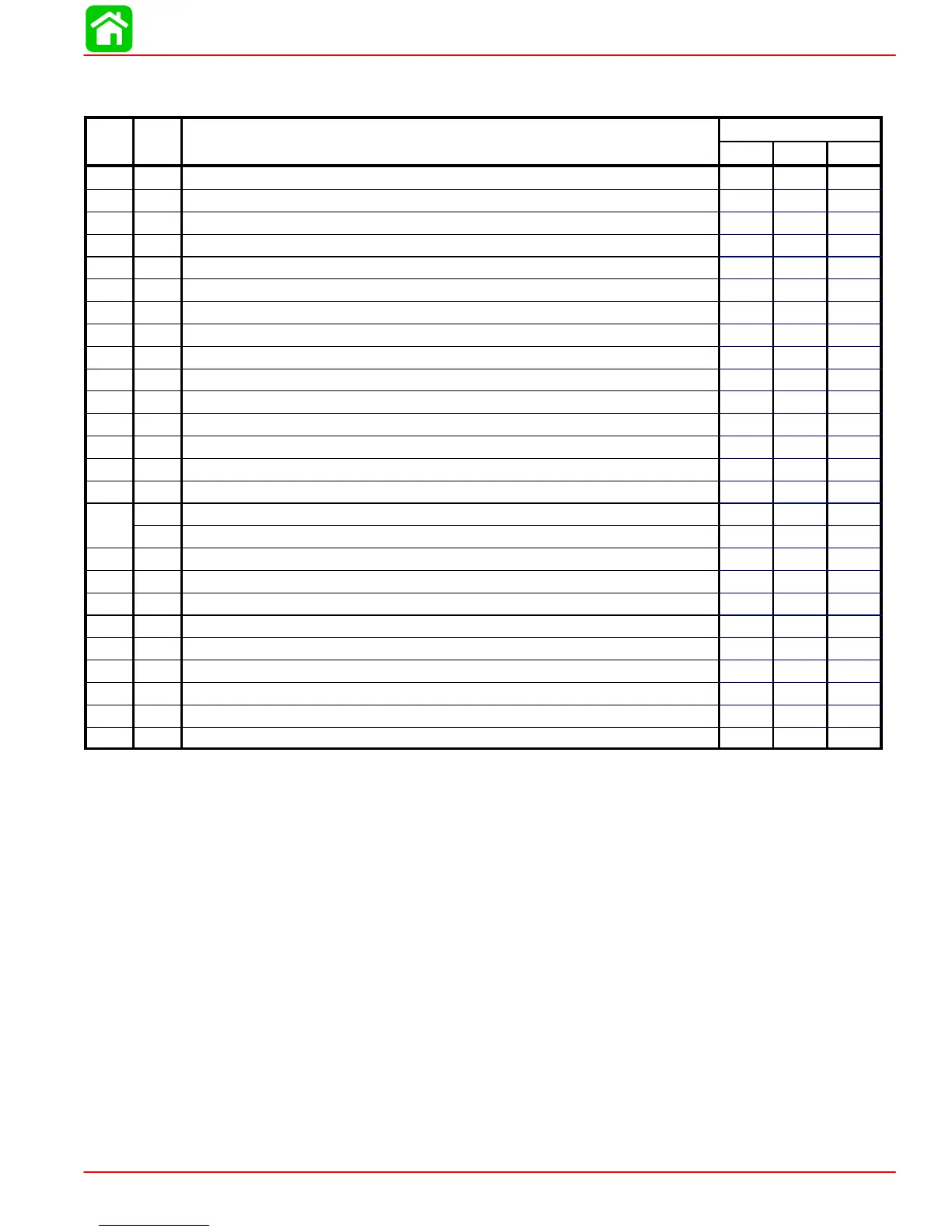

Fuel Pump

TORQUE

.

NO.

QTY. DESCRIPTION lb-in lb-ft Nm.

1

1

FUEL PUMP ASSEMBLY

2 2 DIAPHRAGM KIT

3 1 DIAPHRAGM

4 2 RUBBER CHECK VALVE

5 2 RETAINER

6 1 SPRING

7 1 CAP

8 1 SPRING

9 1 CAP

10

1

DIAPHRAGM

11 1 GASKET

12 1 GASKET–boost

13 1 GASKET–pulse

14 1 PLATE

15 2 FITTING

2 SCREW–fuel pump (M5 x 40) 55 6

2 SCREW–pump to crankcase (M6 x 50) 55 6

17 1 BASE

18 1 ELBOW (45 Degrees)

19 1 FITTING

20 1 TUBING (6 IN.)

21 5 STA STRAP

22 1 HOSE (W/Insulating Sleeve) (7 in.)(177.8 mm)

23 1 HOSE (W/Insulating Sleeve) (18 in.)(457.2 mm)

24 1 CONNECTOR

25 1 CLAMP

Fuel Pump Description/Operation

The fuel pump is a crankcase-pressure-operated, diaphragm-type pump. Crankcase pul-

sating pressure (created by the up-and-down movement of piston) is transferred to fuel

pump by way of a passage (hole) between crankcase and fuel pump.

When piston is in an upward motion, a vacuum is created in the crankcase, thus pulling

in a fuel/air mixture [from Vapor Separator Tank (VST)] into crankcase. This vacuum also

pulls in on the fuel pump diaphragm, thus the inlet check valve (in fuel pump) is opened

and fuel (from fuel tank) is drawn into fuel pump.

Downward motion of the piston forces the fuel/air mixture out of the crankcase into the

cylinder. This motion also forces out on the fuel pump diaphragm, which, in turn, closes

the inlet check valve (to keep fuel from returning to fuel tank) and opens the outlet check

valve, thus forcing fuel to the VST.

Loading...

Loading...