DIRECT FUEL INJECTION

Page 3B-52 90-855347R1 JANUARY 1999

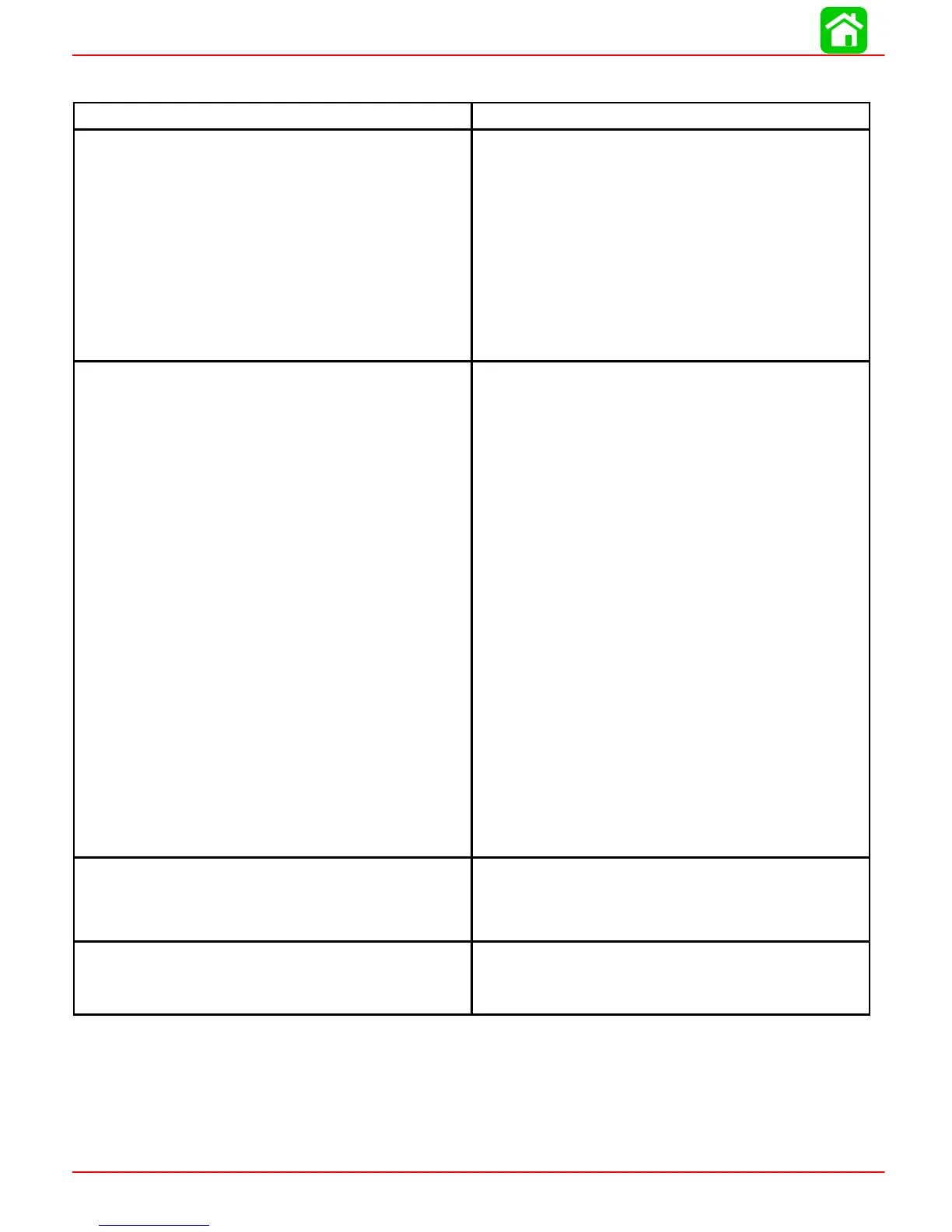

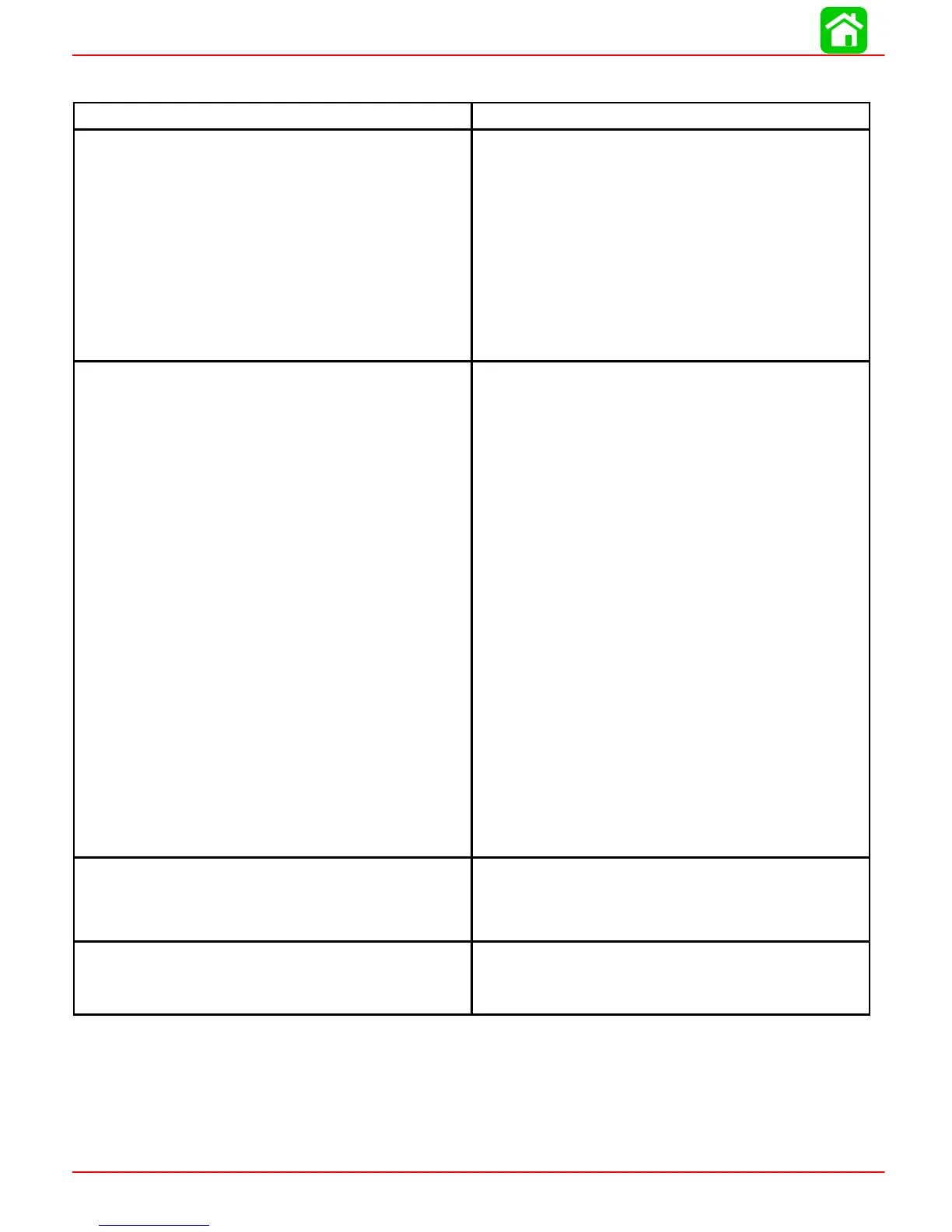

FUEL PRESSURE AND AIR PRESSURE TROUBLESHOOTING CHART

PROBLEM CORRECTIVE ACTION

Fuel Pressure and Air Pressure are Both Low 1. Inspect air compressor air intake (air filter in fly-

wheel cover) for blockage.

2. Remove air compressor cylinder head and in-

spect for scuffing of cylinder wall. Inspect for bro-

ken reeds and/or reed stops.

3. Tracker Valve – Remove and inspect diaphragm

for cuts or tears and seat damage on diaphragm

and rail.

4. Air Regulator – Remove and inspect diaphragm

for cuts or tears on diaphragm and rail.

Fuel Pressure Low or Fuel Pressure Drops while

Running (Air Pressure Remains Normal)

1. Each time key is turned to the RUN position, both

electric pumps should operate for 2 seconds. If

it they do not run, check 20 ampere fuse and wire

connections.

2. If pumps run but have no fuel output, check va-

por separator (remove drain plug) for fuel.

3. If no fuel present in vapor separator, check fuel/

water separator for debris. Check crankcase

mounted fuel pump for output.

4. Check high pressure pump amperage draw.

Normal draw is 6 - 9 amperes; if draw is below 2

amperes, check fuel pump filter (base of pump)

for debris. If filter is clean, replace pump. If am-

perage is above 9 amperes, pump is defective –

replace pump.

Check low pressure output – 6-9 psi.

Check low pressure electric fuel pump amper-

age draw. Normal draw is 1 - 2 amperes; if draw

is below 1 ampere, check for blockage between

pump inlet fitting and vapor separator tank. If am-

pere draw is above 2 amperes, replace pump.

5. Fuel Regulator – Remove and inspect dia-

phragm for cuts or tears.

Fuel Pressure High and Air Pressure is Normal 1. Stuck check valve in fuel return hose.

2. Debris blocking fuel regulator hole.

3. Faulty pressure gauge

Fuel and Air Pressure Higher than Normal 1. Debris blocking air regulator passage.

2. Air dump hose (rail to driveshaft housing)

blocked/plugged.

Loading...

Loading...