POWERHEAD

Page 4A-30 90-855347R1 JANUARY 1999

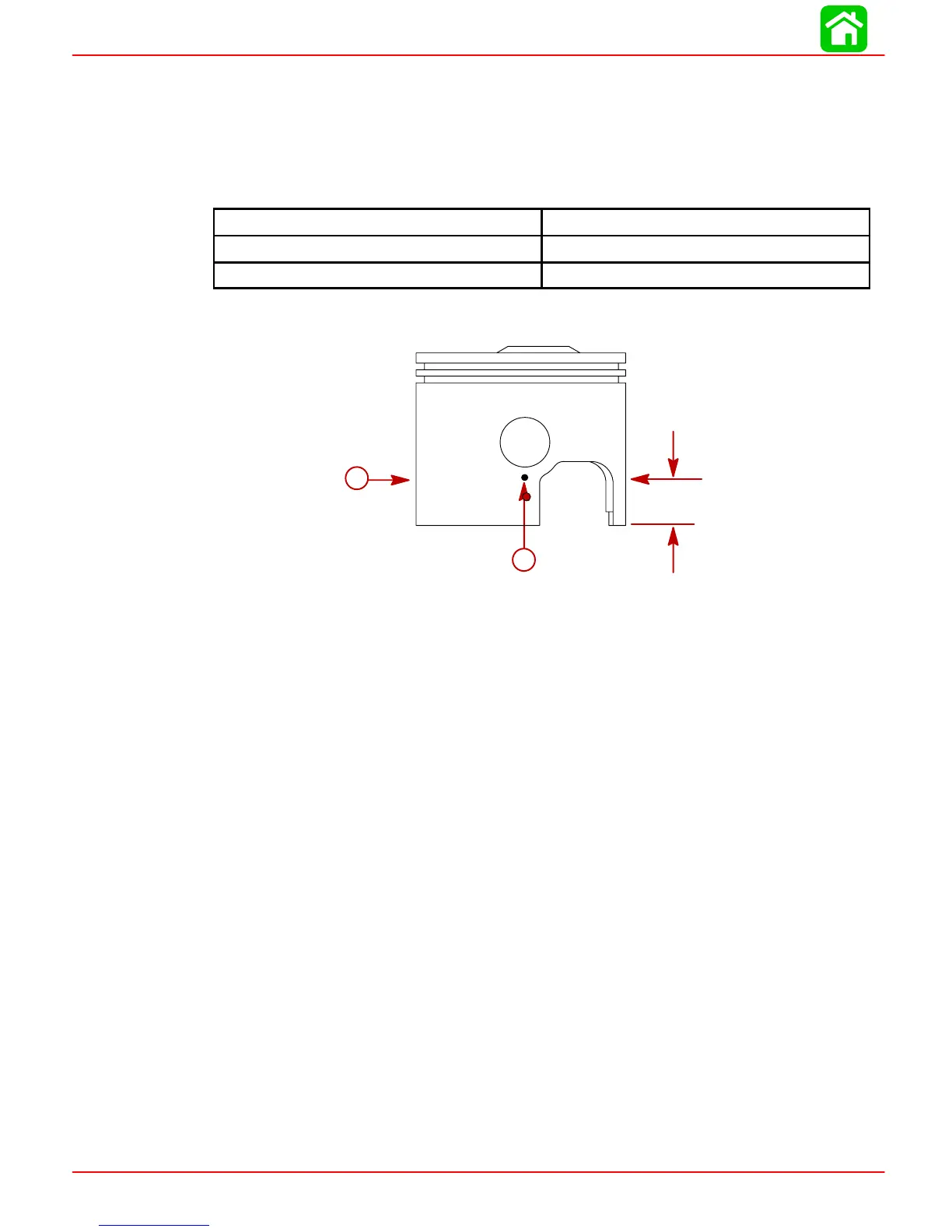

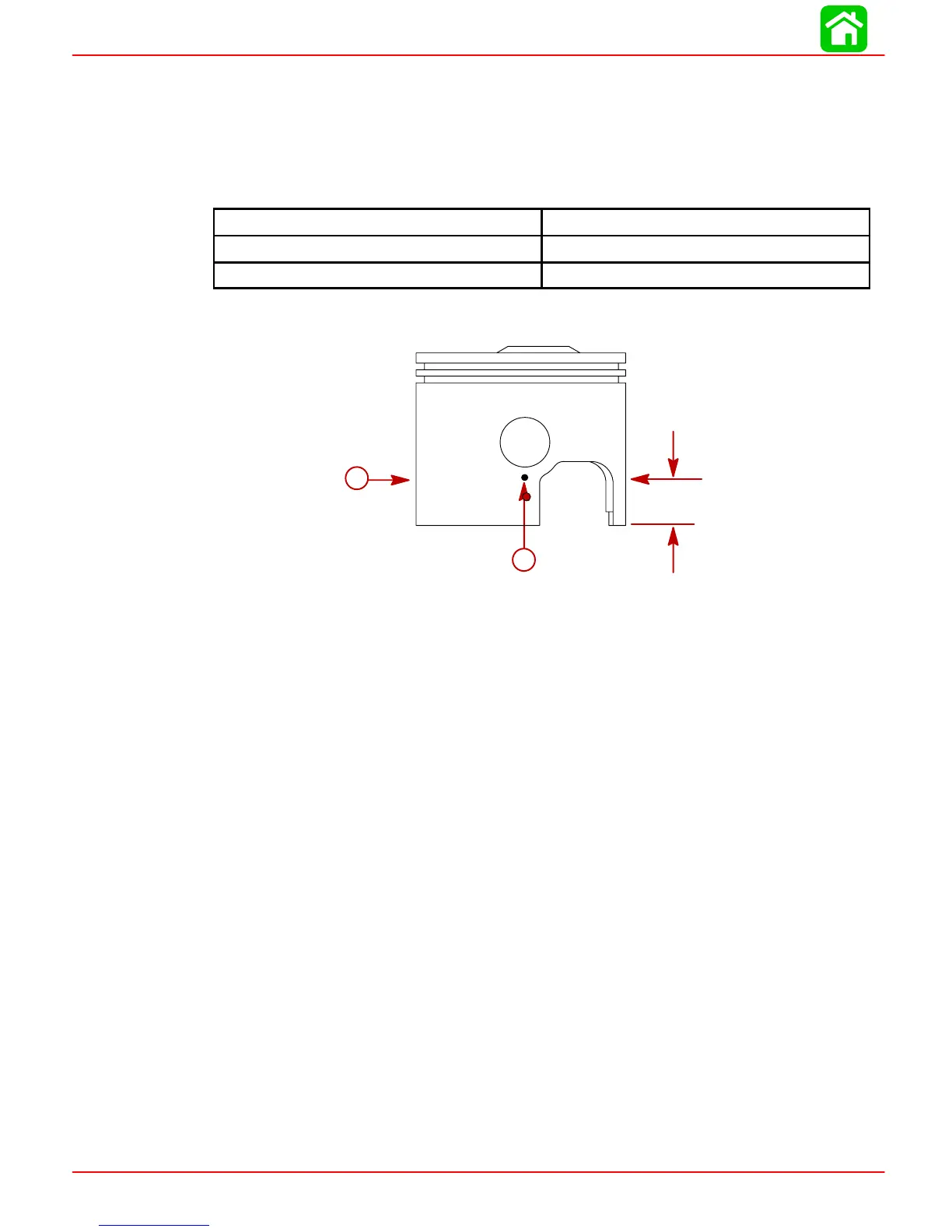

MEASURING PISTON ROUNDNESS

Piston has a barrel profile shape and is not a true diameter.

Standard 135/150 Models - 153 cu. in. (2508 cc)

1. Using a micrometer, measure dimension “A” at location shown. Dimension “A” should

be as indicated in chart following.

Piston Dimension “A”

Standard Piston 3.4925 in. ± 0.0005 in.

0.015 in. Oversize Piston 3.5075 in. ± 0.0005 in.

2. Using a micrometer, measure dimension “B” at location shown. Dimension “B” should

be within 0.008 in. of dimension “A.”

0.700 in.

(17.78mm)

a

b

a-Dimension “A” at RIGHT Angle (90°) to Piston Pin

b-Dimension “B” (in line with Piston Pin)

Cylinder Heads and Exhaust Divider Plate

1. Inspect internal surface of cylinder heads for possible damage (as a result of piston

or foreign material striking cylinder heads).

IMPORTANT: Cylinder head warpage should not exceed 0.004 in. (0.1 mm) over the

ENTIRE length of the cylinder head. If measured warpage, as determined on a sur-

face block, exceeds 0.004 in. (0.1 mm) or a discontinuity of up to 0.004 in. (0.1 mm)

exists in a narrow portion of the cylinder head’s surface length, then the cylinder

head may be re-surfaced up to 0.010 in. (0.25 mm).

2. Replace cylinder head(s) as necessary.

3. Thoroughly clean gasket surfaces of exhaust divider plate.

4. Inspect exhaust divider plate for deep grooves, cracks or distortion that could cause

leakage. Replace parts as necessary.

Crankshaft

1. Inspect crankshaft to drive shaft splines for wear. (Replace crankshaft, if necessary.)

2. Check crankshaft for straightness. Maximum runout is 0.006 in. (0.152 mm). (Replace

as necessary.)

3. Inspect crankshaft oil seal surfaces. Sealing surfaces must not be grooved, pitted or

scratched. (Replace as necessary.)

4. Check all crankshaft bearing surfaces for rust, water marks, chatter marks, uneven

wear and/or overheating. (Refer to “Connecting Rods”.)

Loading...

Loading...