39

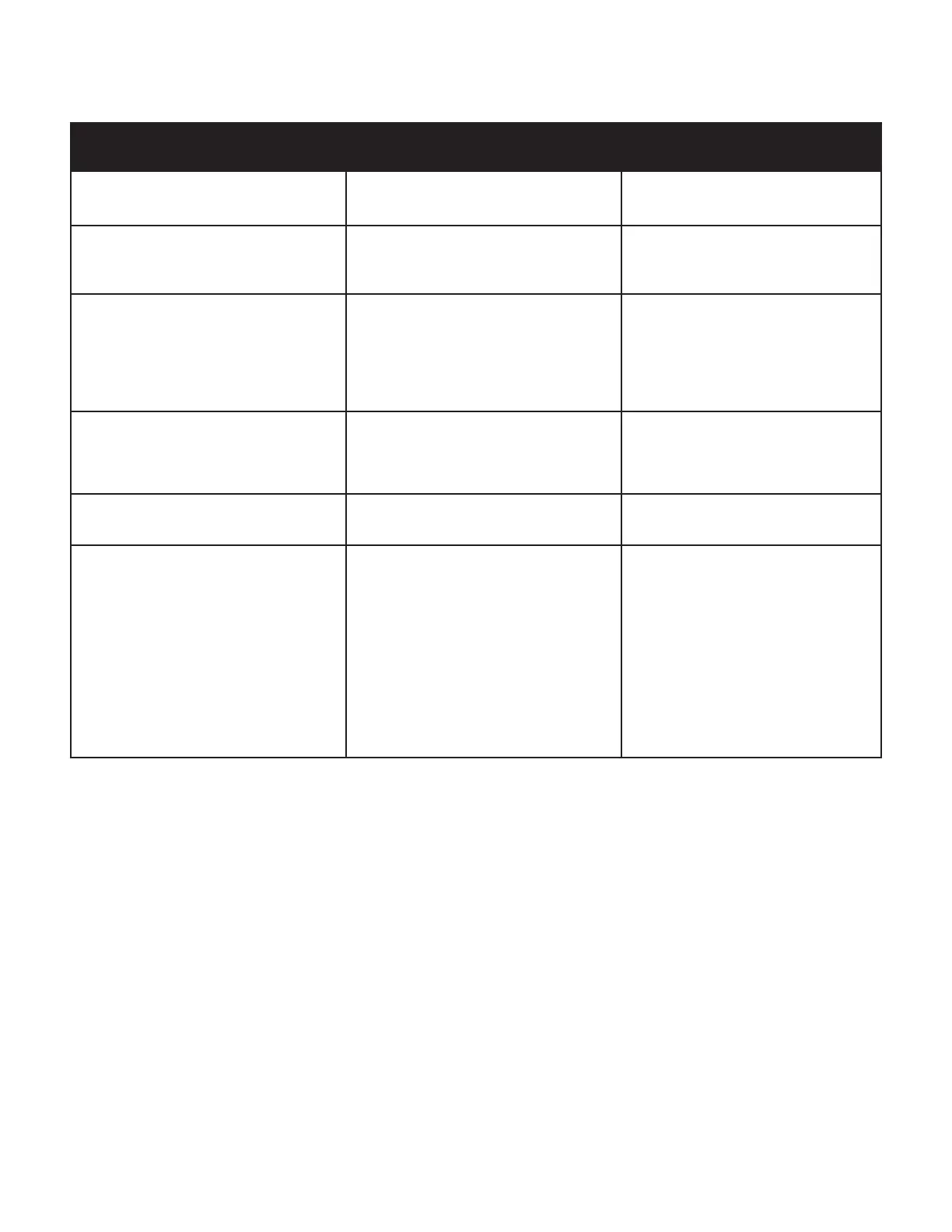

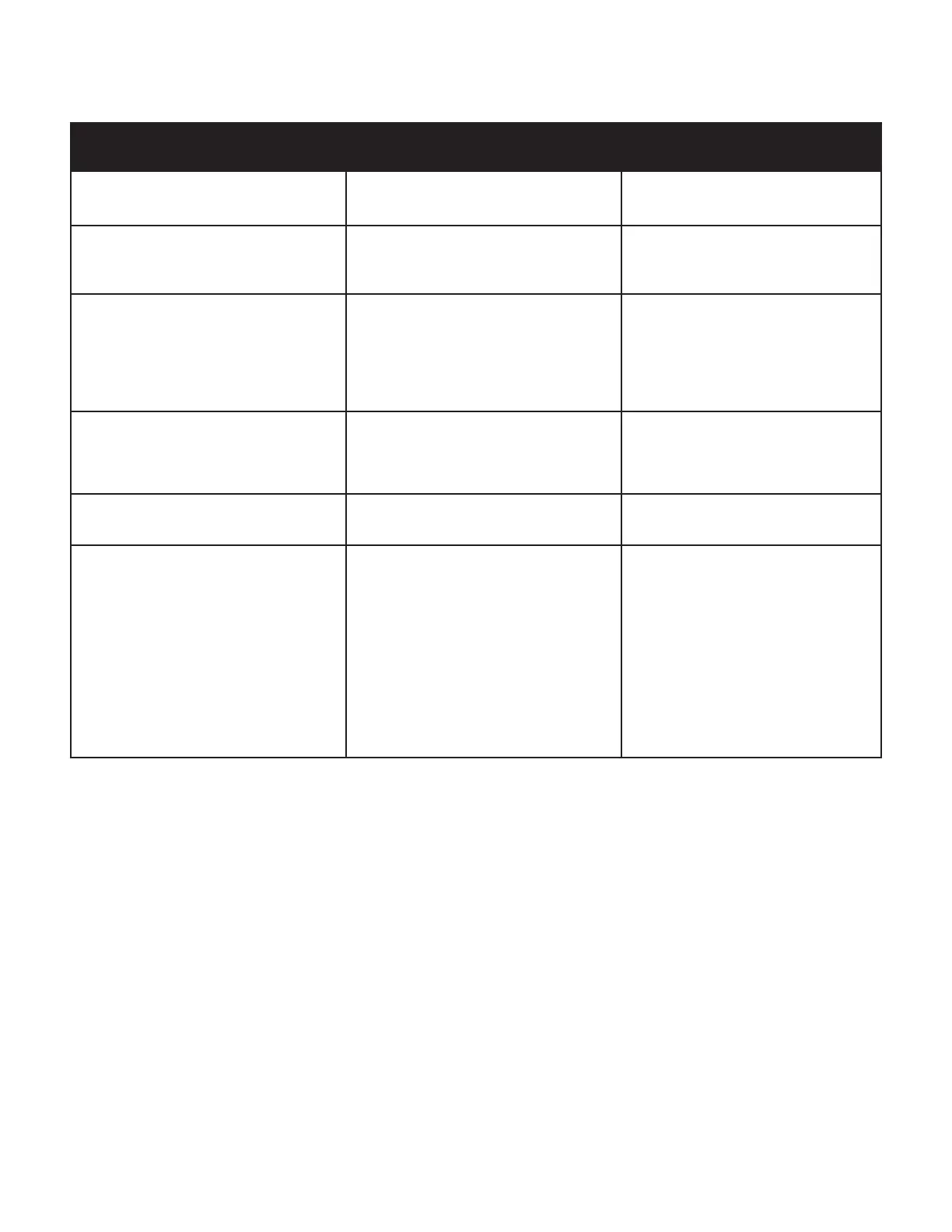

Plumbing Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE POSSIBLE SOLUTION

Loses pressure in MAN Pump Airlock Clean strainer

Larger hoses

Little or no pressure Too much restriction Larger hoses and fittings

a

djustment in MAN in servo loop

No sharp bends

Pressure won’t go high Pump starved or too small Larger hoses

enough in MAN

Too much agitation Reduce agitation

Throttle, range adjust Adjust

or pressure relief valves

Pressure, speed and spray Inaccurate pressure reading Use a different gauge

rate don’t check out and check each boom

according to tip charts

Dirty or worn tips Clean or replace

Pressure always goes Minimum flow rate too high Recalibrate

too high in AUTO Online/bypass setting Set appropriately

Pressure fluctuates Sagging or kinked hoses Support or replace hoses

greatly in AUTO

Throttle valve too far closed Adjust throttle

and range valves

Pump starved or too small Larger hoses

Larger pump

Clean strainer

Valve response speed set too high Reduce valve speed setting

(Special Cal)

Loading...

Loading...