64

WIDTH

CAL

FLOW

CAL

MIN

FLOW

A

DJUST

RATE

TARGET

RATE

SPEED

CAL

INLINE

BYPASS

TEST

SPEED

V

OLUME /

MINUTE

DISTANCE

AREA /

HOUR

VOLUME

(1) (2) (3)

RATE

SPEED

AREA

(1) (2) (3)

TANK

CAL

AUTO

MAN

RESET

MANAUTO

CALHOLD

_

____

_____

H

OLD

1

S

pray

M

ate

II

This procedure is used to verify and fine-tune the

flowmeter calibration. Every flowmeter is calibrated with

water at the factory and stamped with a calibration value.Enter that

value as a starting point and use this procedure to fine-tune that

value for your specific installation and NH3 application (please refer

to Entering Flowmeter Calibration Value, page 26).

PROCEDURE:

1. Start with a full nurse tank. Make certain that you have an

accurate scaled weight of the full tank.You will want to apply a

minimum of 1,000 pounds of NH3 for this procedure.The larger

the volume of NH3 used, the more accurate the calibration will

be.

2. With Boom 1 switch turned OFF, turn the rotary selector to the

VOLUME (1) (2) (3) position. Select which pair of VOLUME/AREA

counters (1, 2, or 3) that you want to use by using the "+"

button ONLY to select the pair of counters as identified by the

small number in the lower right area of the left-hand display. If

you attempt to use the "-" button, it will clear the selected

counter pair (CLEAr will be displayed before the counters are

cleared). After you have selected the counter pair number,

press and hold the RESET button until the display reads 0.0.

3. Proceed to the field and perform actual application (turn Boom

1 switch to ON) until at least 1,000 pounds of NH3 has been

applied. (One nurse tank is preferred).The larger the volume of

NH3 applied, the more accurate the calibration will be. Obtain

an accurate scaled weight of the partially used nurse tank. The

difference between the starting and ending weight is your

calibration weight.

4. Put Boom 1 switch in the OFF position. Compare the console’s

VOLUME reading with the known amount of NH3 run. If the

two amounts are within one or two percent, no fine tuning is

required. If the two amounts are more than two or three

p

ercent different, continue with the next step.

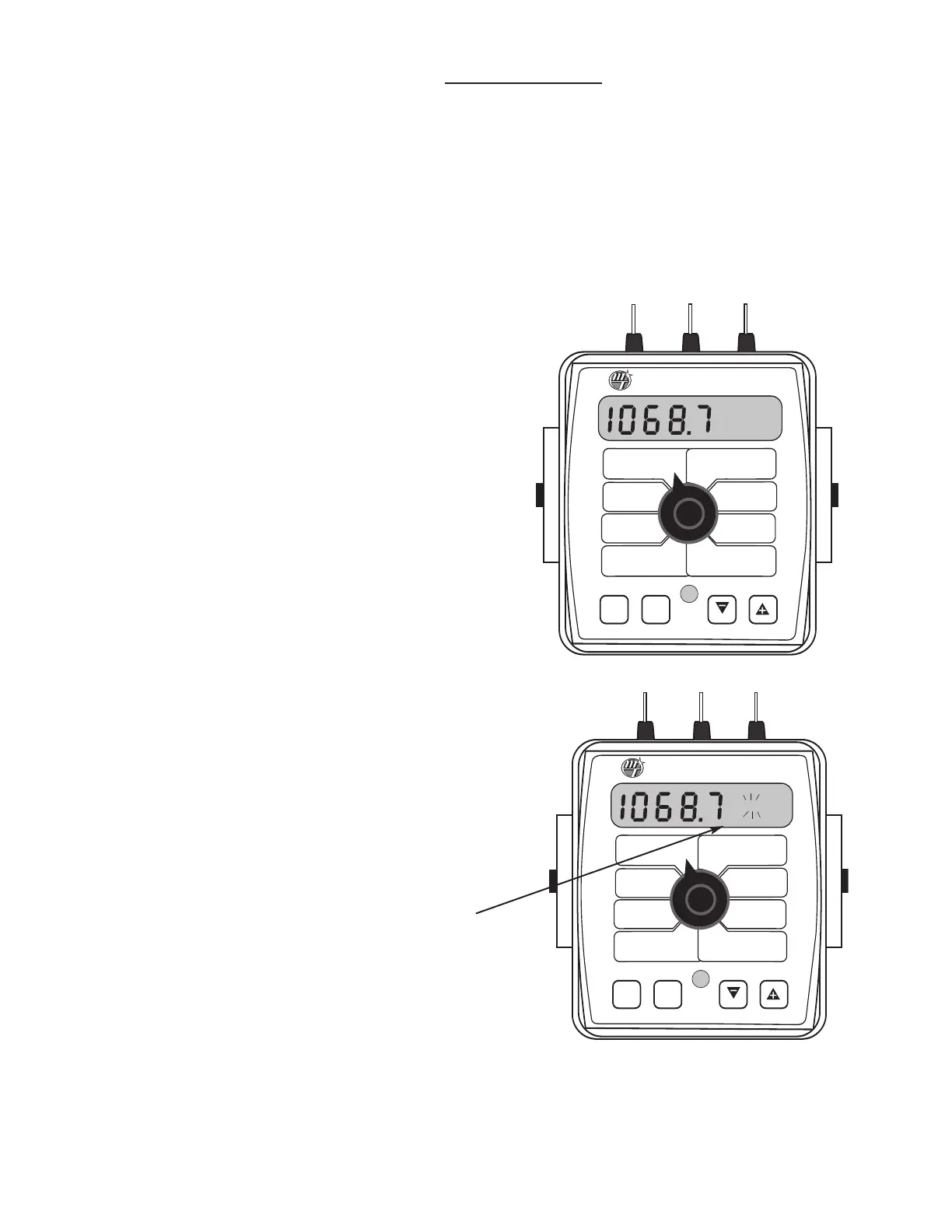

5. With the console still in the VOLUME position, enter calibration,

hold the CAL button until red warning light comes on; about

one second. The display will show the flowmeter calibration

value and the CAL icon.

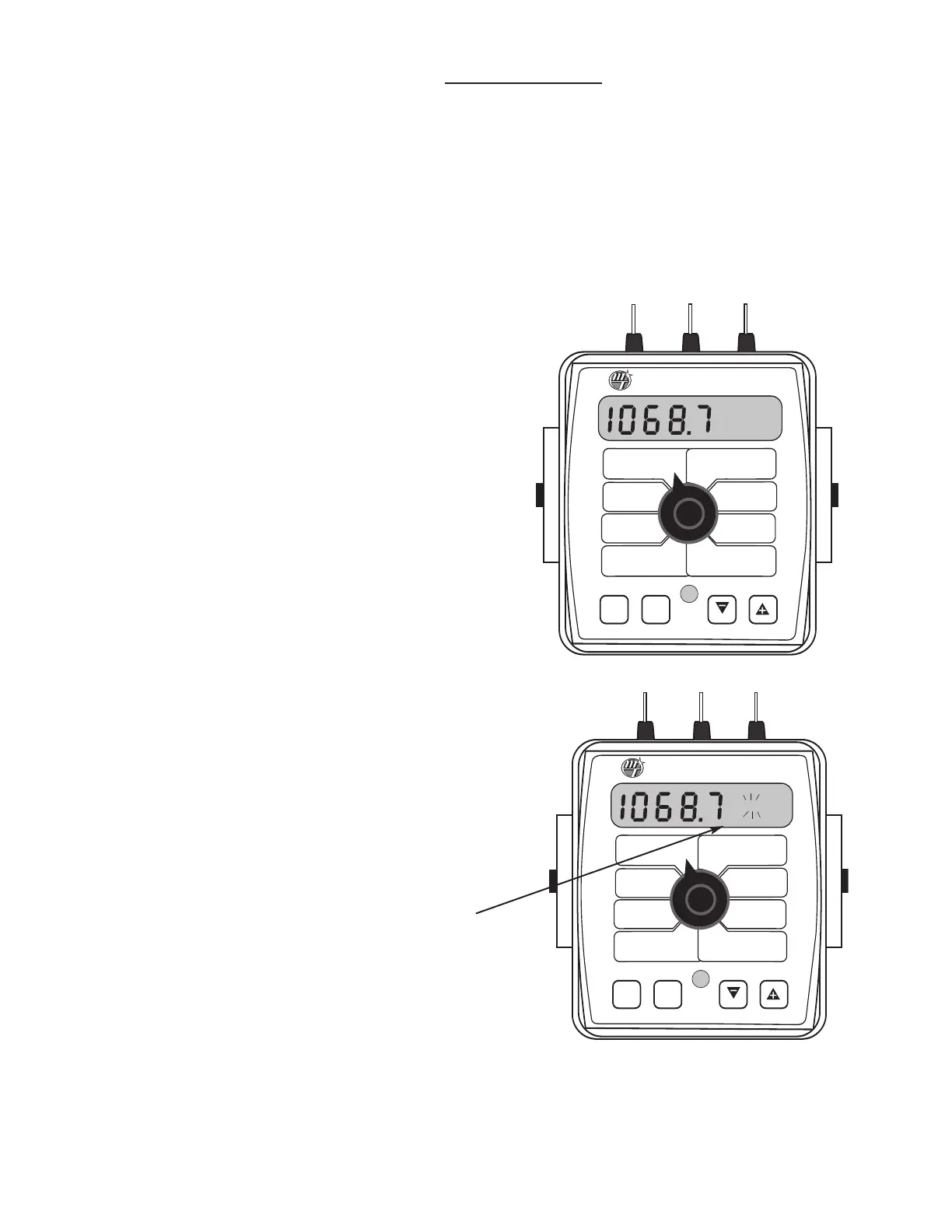

6. Momentarily press the CAL button. The CAL icon will begin to

flash and the t

otal volume will be displayed.

S

ee Illustration.

7.

W

hen the

TOTAL FLOW value is displayed, use the “+” or

“-”button to adjust the value to match the amount of NH3 run.

8.

M

omen

tar

ily pr

ess the CAL button. The CAL icon and the

flowmeter calibration number will be displayed. You will notice

that the flowmeter calibration value has changed. Write down

the new flo

wmet

er c

alibr

a

tion value. This is your “fine tuned”

calibration value, keep it for future reference.

9. Exit calibration by holding the “CAL” button until the red

w

ar

ning ligh

t go

es out (ab

out one sec

ond).

WIDTH

CAL

FLOW

CAL

MIN

FLOW

ADJUST

RATE

TARGET

RATE

SPEED

CAL

INLINE

BYPASS

TEST

SPEED

VOLUME /

MINUTE

DISTANCE

AREA /

HOUR

VOLUME

(1) (2) (3)

RATE

SPEED

AREA

(1) (2) (3)

TANK

CAL

AUTO

MAN

RESET

_____

_____

CAL HOLD

1

S

pray

M

ate

II

Appendix G: SprayMate II - NH3 Specific

Fine Tuning Flow Calibration Value - NH3

Loading...

Loading...