43

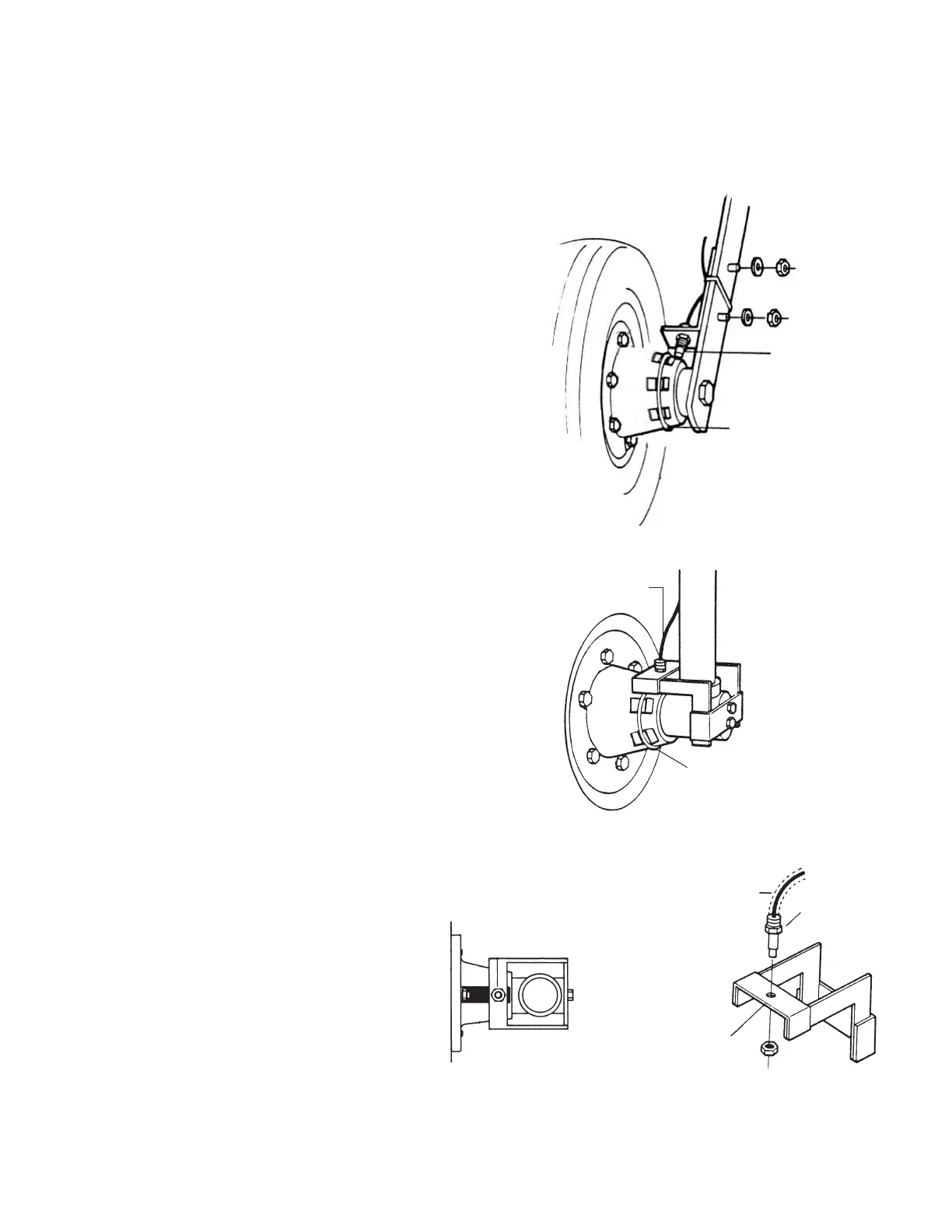

Implement Wheels

1. Secure magnets mechanically or with epoxy.

2. Rigidly mount sensor mounting bracket to the wheel

assembly. Cut or bend “L” bracket as required for proper

positioning of sensor.

3. Install sensor, adjust to correct spacing (1/4" to 1/2 " or 6 to

13 mm is recommended), and secure with 3/8" locking nuts.

See Illustration at right.

Cable tie

Speed Sensor

1/4" bolts,

lockwashers

a

nd nuts

Speed Sensor

and Bracket

Front Tractor Wheel

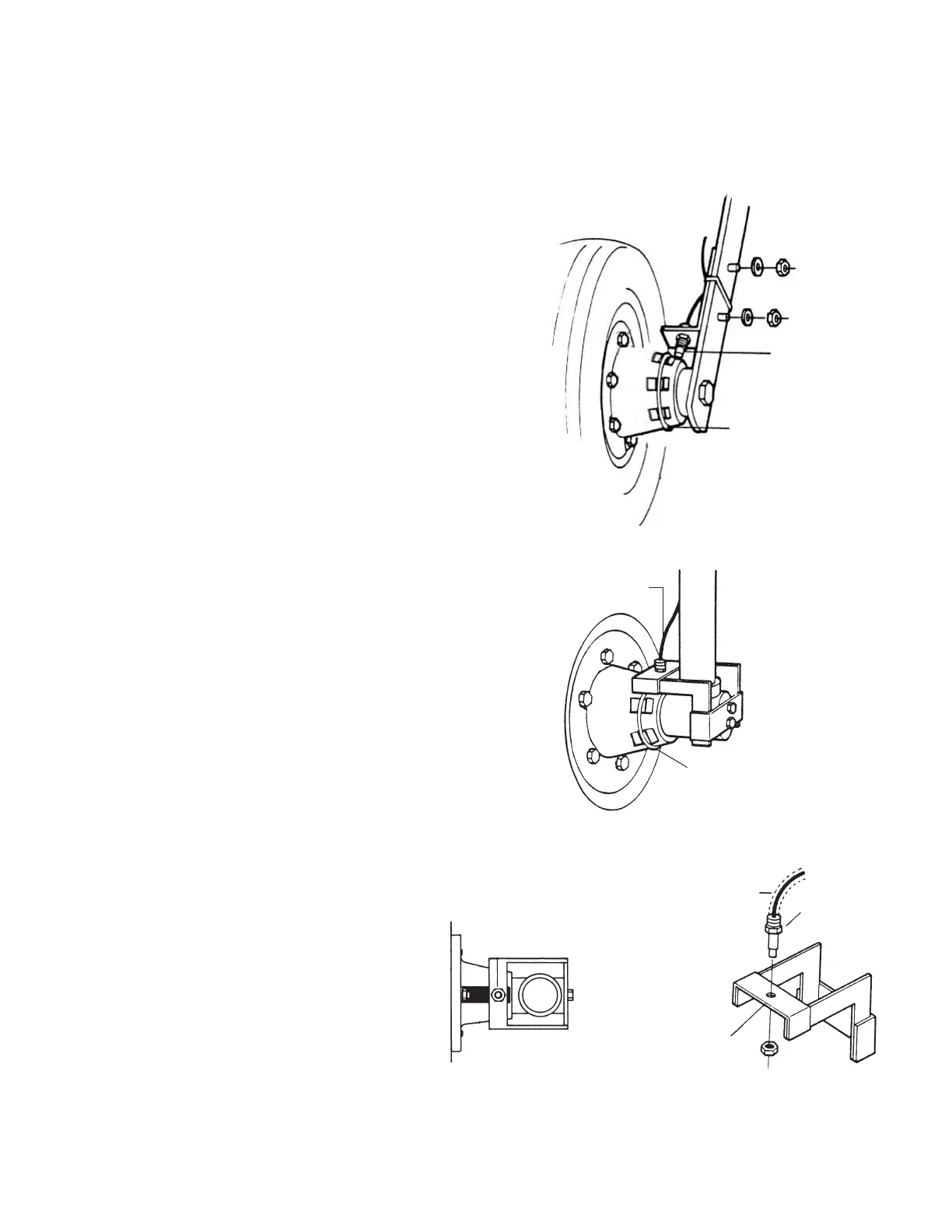

1. Magnets may also be secured with a cable tie and an

adhesive such as epoxy.

2. Mount the speed sensor bracket to a part of the wheel

assembly that does not change position to the hub when the

wheels are turned. If the “L” bracket provided cannot be bent

and mounted to properly position the sensor, make a bracket

similar to the one shown at right.

3. Install sensor, adjust to correct spacing (1/4" to 1/2 " or 6 to

13 mm is recommended), and secure with 3/8" locking nuts.

Tap thread for

bolts, or weld

Fabricated Bracket

S

ensor

3/8" nut

Top view

Speed Sensor

Cable tie

Hub

Optional section of hose

to protect cable.

3/8" nut

3/8" hole

for Sensor

Appendix A:

Optional Speed Sensor Mounting Installation

Loading...

Loading...