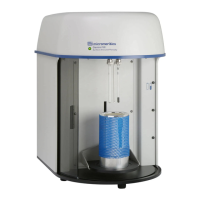

The SmartPrep 065 is a degasser designed to prepare samples for adsorption analysis by removing adsorbed contaminants from their surface and pores. It features six independently controlled heating stations, allowing for simultaneous degassing of up to six samples.

Function Description:

The primary function of the SmartPrep 065 is to degas samples using a flowing gas method. Each heating station has individual gas flow controls, enabling users to adjust the gas flow rate to each station. Status indicators on the front panel provide real-time information on the current state of each heating station. The device is controlled by SmartPrep software, which allows users to define degas conditions, initiate automatic or manual degas operations, and monitor the progress of these operations. The software can be run as an embedded program within Micromeritics TriStar 3000 analysis system software or as a standalone program for degassing samples prior to analysis on any system.

Important Technical Specifications:

- Degas Method: Flowing gas

- Number of Stations: Six

- Temperature Range: Ambient to 425 °C, with 1 °C increments. Each station is controlled separately.

- Temperature Accuracy:

- ±5 °C for set points up to 100 °C

- ±10 °C for temperatures between 100 °C and 300 °C

- ±15 °C for temperatures over 300 °C

- Soak Time: 0 to 999 minutes, in 1-minute increments

- Ramp and Soak Cycles: Up to 5 ramp and soak cycles

- Ramp Rate: From 5 °C/min. to 20 °C/min.

- Electrical:

- Voltage: 85 to 265 VAC

- Power: 500 VA Maximum

- Frequency: 50/60 Hz

- Environment:

- Operating Temperature: 10 to 35 °C

- Non-operating Temperature: 0 to 50 °C

- Humidity: 20 to 80% relative, noncondensing

- Gases Used: Nitrogen and other inert gases

- Gas Flow Rate: 0 - 500 cm³/min.

- Physical Dimensions:

- Height: 50 cm (20 in.)

- Width: 50 cm (20 in.)

- Depth: 40 cm (16 in.)

- Weight: 15 kg (33 lbs)

- Connectivity: Two RS-232 serial ports. One for connection to the control module, and the other for connecting an additional SmartPrep unit. Up to four SmartPreps can be connected, providing up to 24 heating stations.

Usage Features:

- Independent Station Control: Each of the six heating stations can be controlled independently for gas flow and temperature.

- Gas Flow Control Knobs: Allow manual adjustment of gas flow to each station. When pressure is set to 15 psi (103 kPa) and a valve is fully opened, the flow rate is approximately 100 cm³/min.

- Status Indicators: Each heating station has three lights (green, yellow, red) to indicate its current status:

- Ready (Green): Set point temperature below 30 °C and actual temperature below 60 °C (idle and not hot).

- Cooling (Yellow): Set point temperature less than 30 °C and actual temperature greater than 60 °C.

- Heating (Red): Set point temperature greater than 30 °C and heat is being applied.

- Lights flash when gas is flowing through the heating station.

- Sample Information Files: Users can create and manage sample information files, which include sample identification and degas conditions. These files can be in Basic or Advanced format, with the Advanced format offering more detailed parameter editing.

- Degas Conditions Files: Degas conditions (Soak Temperature, Temperature Ramp Rate, Soak Time) can be saved as separate files and reused across multiple sample files. Up to five stages of degas conditions can be entered.

- Heating Station Adapters: The SmartPrep supports various sample tubes (TriStar 3000, ASAP 2000, ASAP 2010, Gemini) through specific heating station adapters. Isothermal shields are used with ASAP/TriStar tubes to maintain uniform temperature.

- Automatic and Manual Degas Operations: The software allows for both automated degas operations based on predefined conditions and manual control of temperature and gas flow.

- Monitoring: The SmartPrep Status dialog box provides real-time monitoring of degas operations, including sample name, current status (Idle, Ramping, Soaking, Cooldown), current temperature, and gas valve status.

- Reports: The system can generate log reports detailing degas operations.

- User Interface: The SmartPrep software features a menu-driven interface (File, SmartPrep, Reports, Options, Windows, Help) for easy navigation and control.

Maintenance Features:

- Power Supply Dust Filter Replacement: The power supply dust filter, located on the back of the unit, should be checked every 30 days (or more frequently in dusty environments) and replaced if accumulated with dust. Filters are provided in the accessories kit.

- Flow Rate Verification: The gas flow rate for each port should be verified every 3 to 6 months to ensure proper gas flow. This can be done by observing bubbles in water or using a precision flow meter, and adjusting the gas flow control knob as needed.

- Cleaning Sample Tubes: Sample tubes and filler rods must be thoroughly cleaned and dried before use, following a recommended procedure involving ultrasonic cleaning, rinsing with isopropyl alcohol or acetone, and drying in an oven.

- Safety Precautions: The manual emphasizes safety warnings, particularly regarding hot heating stations and adapters, advising the use of proper gloves and tools to prevent burns. It also warns against piercing the sample bed with the gas delivery tube to avoid clogging.