The distance calculation may be converted to space, material level, material volume, remaining vessel

capacity, differential level, or average level Readings. The Reading chosen (and operating data) for each

vessel is displayed on the

Liquid Crystal Display

(LCD).

The relays and mA outputs may be used as preset (or programmed as desired) to activate alarms and/or

operate remote monitoring equipment and/or process control equipment.

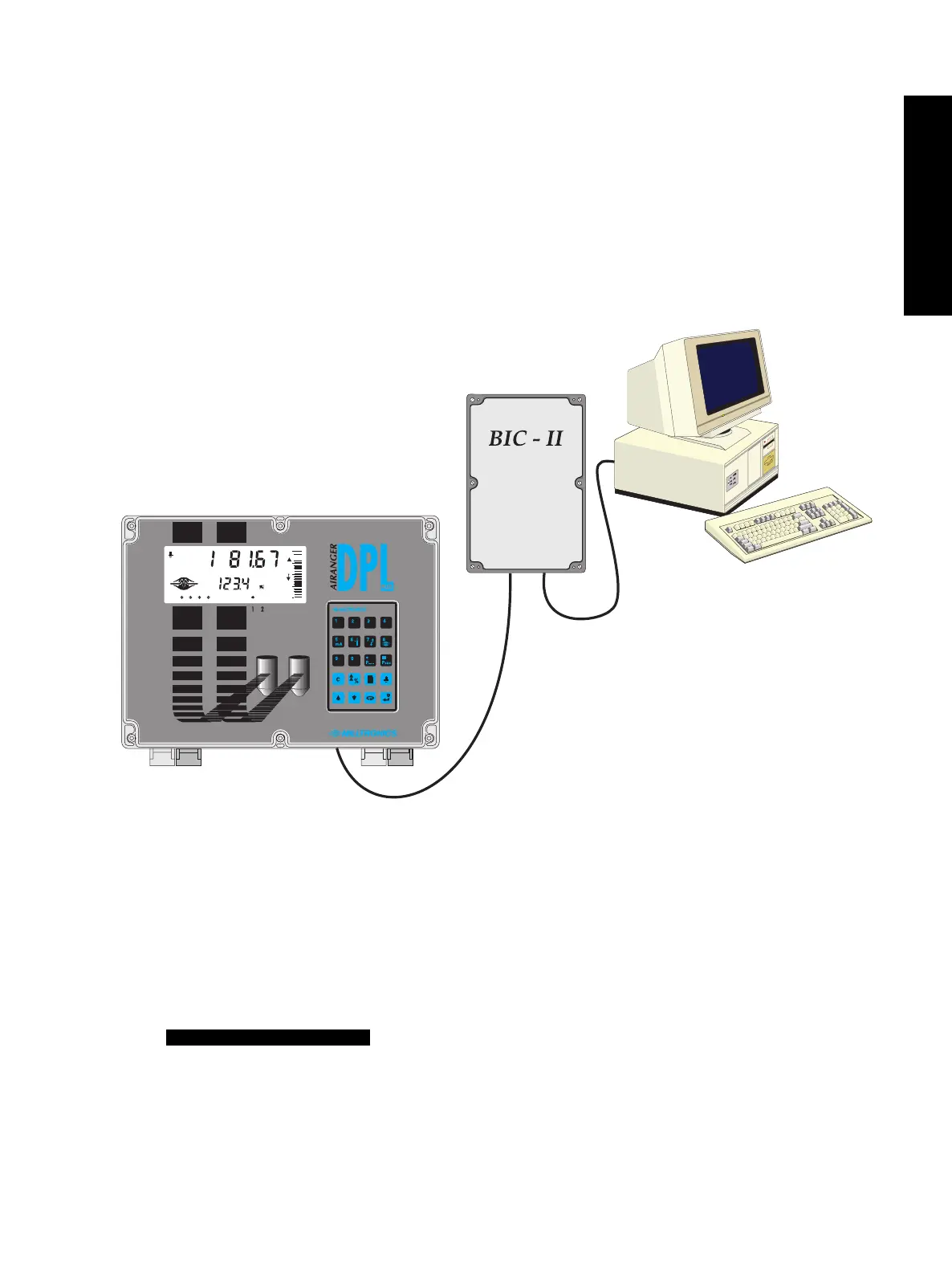

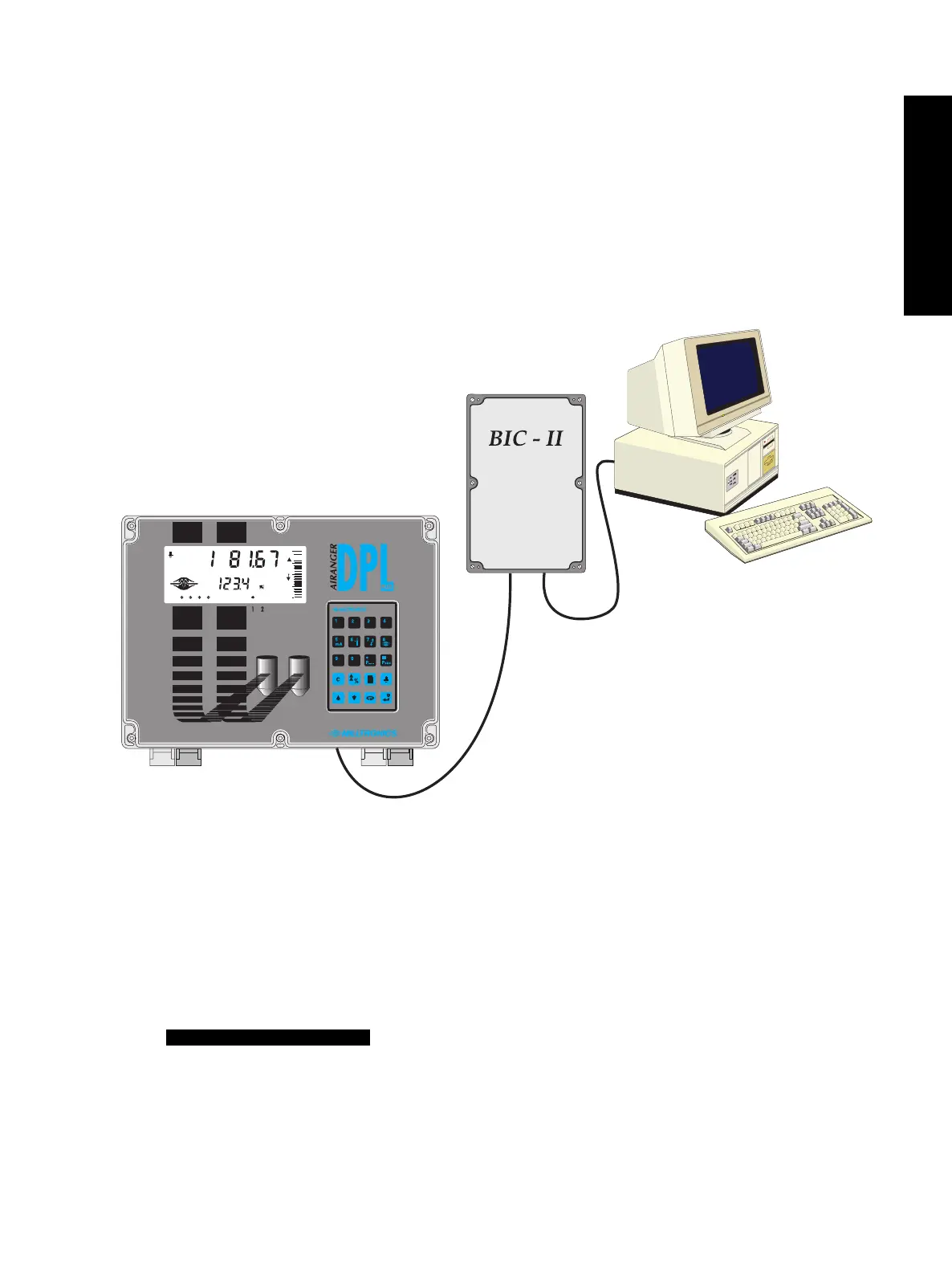

As well, the DPL+ may be connected to a Milltronics

BIC-II

(Buffered Interface Converter) to provide

RS-232C and/or RS-422 communications for host computers, Distributed Control Systems, and

special

(capable of operating as a host device) Programmable Logic Controllers.

Operator programming is accomplished using a Milltronics infrared programmer and is stored in non-volatile

memory, unaffected by power interruption. The infrared interface permits one programmer to be used for any

number of DPL+ level monitors. Upon programming completion, the removable programmer may be locked

away, thereby securing all programming.

While the DPL+ is typically used to monitor material level in open or closed vessels, any process which

requires a distance measurement (within the system range) is a candidate for DPL+ application.

Refer to Application Examples for detailed descriptio ns of a small sample of

process measurement requirements to which the DPL+ may be applied. If process or equipment position

monitoring at distances greater than 60 m (200 ft) is required, refer to Example - 6, Tripper Measurement.

Throughout this manual (unless stated otherwise) references to material level also apply to any material or

object surface to be monitored by the DPL+.

TECHNICAL REFERENCE

%

100

0

%

1

234

INTRODUCTION

PL-508 7

Loading...

Loading...