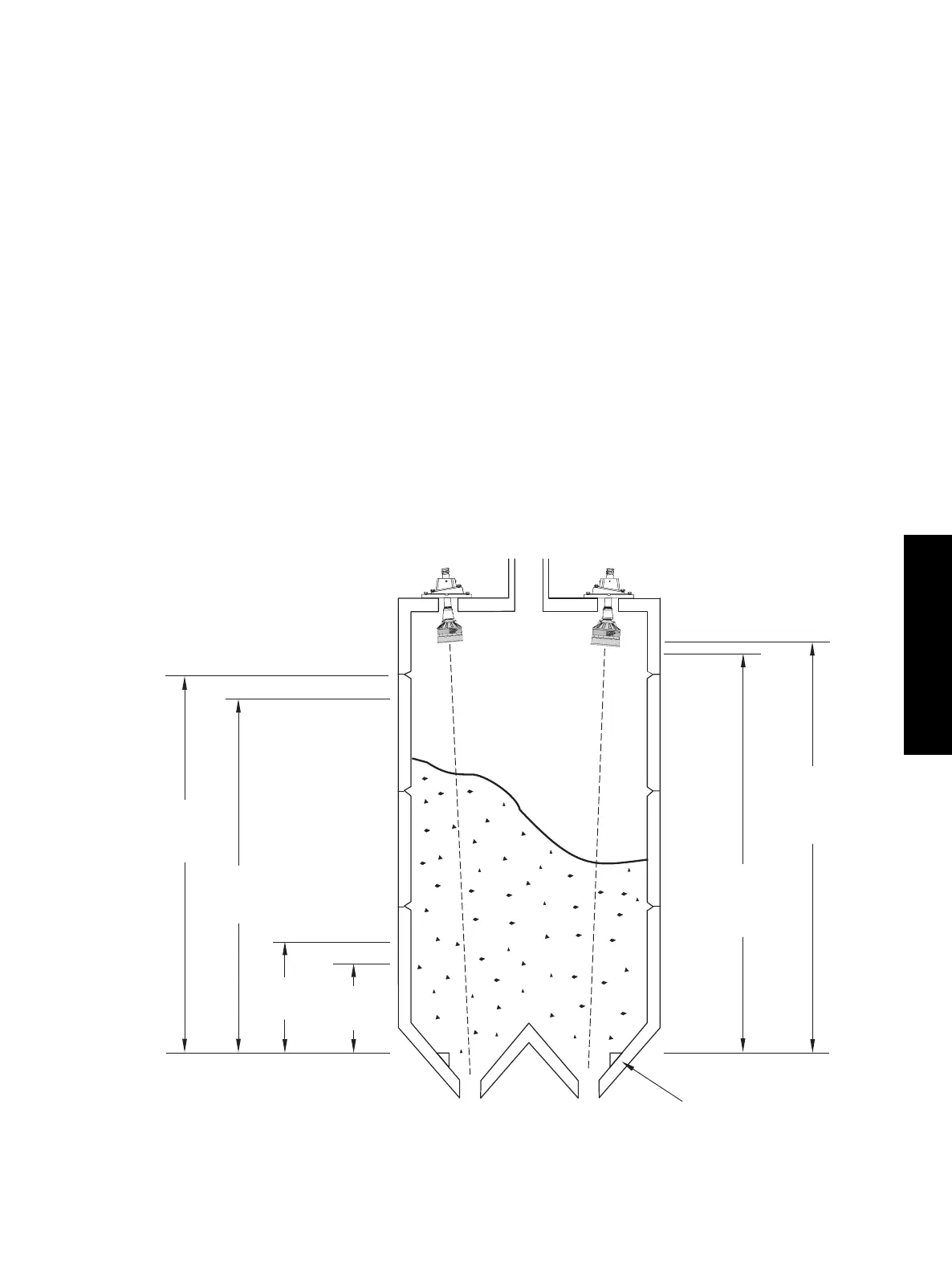

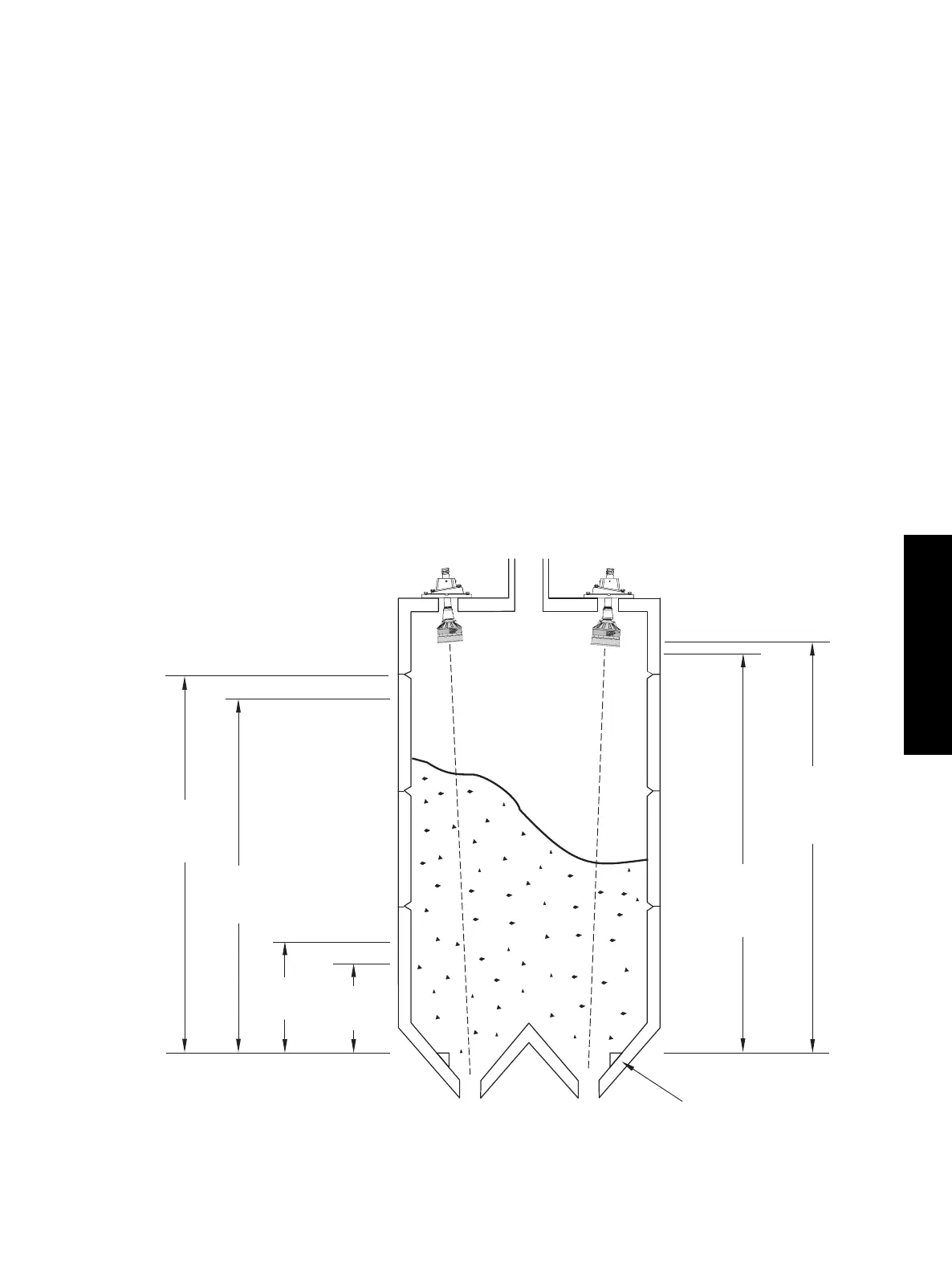

EXAMPLE 5 - DUAL POINT AVERAGE

This mode of operation is commonly used for a dual discharge or wide vessel, where the material profile

within the vessel may vary substantially depending upon vessel filling/emptying activity.

By averaging the measurement results obtained from two transducers aimed at different portions of the

material level profile, an average material level can be attained.

For this example we’ll assume the following:

» a 75 ft tall vessel is used to hold grain outside of an animal feed production plant.

» the vessel discharges into two separate blenders.

» the maximum vessel filling/discharge rate is 6 inches per minute.

» 2 XPS-30 transducers are mounted at the top of the vessel, aimed at each discharge point.

» 2 alarms are required outside to warn of near full and full when the vessel is being filled.

» 2 alarms are required in the production managers office to warn of near empty and empty.

» if a measurement difficulty occurs, the full alarm is to be activated to advise the filling operator.

» if a measurement difficulty occurs, the empty alarm is to be activated to advise the manager.

APPROVED

FM

APPROVED

FM

72.20 ft

(P007)

74.00 ft

(P006)

empty vessel target

4.00 ft

(P104)

6.00 ft

(P102)

68.00 ft

(P101)

70.00 ft

(P 103)

TECHNICAL REFERENCE

PL-508 89

Loading...

Loading...