Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

Unidrive M Regen Design Guide 139

Issue Number: 4

7 Getting started

7.1 Regen parameter settings

7.1.1 Switching frequency Pr 05.018 (Pr 00.041)

Set the switching frequency on the Regen drive to the required value

(3 kHz default value).

A higher switching frequency setting has the following advantages:

• Line current ripple at the switching frequency is reduced, giving

improved waveform quality.

• Acoustic noise produced by the line inductors is reduced.

• Dynamic DC bus voltage response is improved.

N

In some cases, setting the switching frequency to a value greater than

the default 3 kHz results in current derating. Refer to Chapter 10

Technical data on page 276.

7.1.2 DC bus voltage set point

The table below defines the DC Bus voltage set point levels, assuming a

tolerance of ±10 % on the given supply voltage. The minimum value is

defined as the peak input voltage plus some headroom. Headroom is

required by the drive to allow correct control of the current. It is advisable

to set the voltage below the maximum value to give more allowance for

transient voltage overshoots.

Table 7-1 DC bus voltage set point - Pr 03.005 (Pr 00.001)

The DC bus voltage set point, see Pr 03.005 (Pr 00.001), should be set

to a level that is suitable for the AC supply voltage being used. It is very

important that the Regen drive DC bus voltage set point Pr 03.005

(Pr 00.001) is set above the peak AC supply voltage by at least 50 Vac.

7.2 Regen drive sequencing

When a Regen drive is enabled, it goes through a line synchronization

sequence. During this procedure, test pulses are applied to the incoming

line to determine the voltage and phase. When it has been successfully

synchronized to the line, the DC bus voltage controller is enabled and

the DC bus voltage rises to the target voltage.

Only when all of these stages have been completed successfully is the

motoring drive enabled. If at any time there is a fault, or the Regen drive

is disabled, the motoring drive will also be disabled.

This sequence of events is important to prevent damage to the Regen

drive, motoring drive or external power circuit components.

The sequence of events is as follows:

Power applied and power removed 400 V system

(refer to Figure 4-4 on page 42)

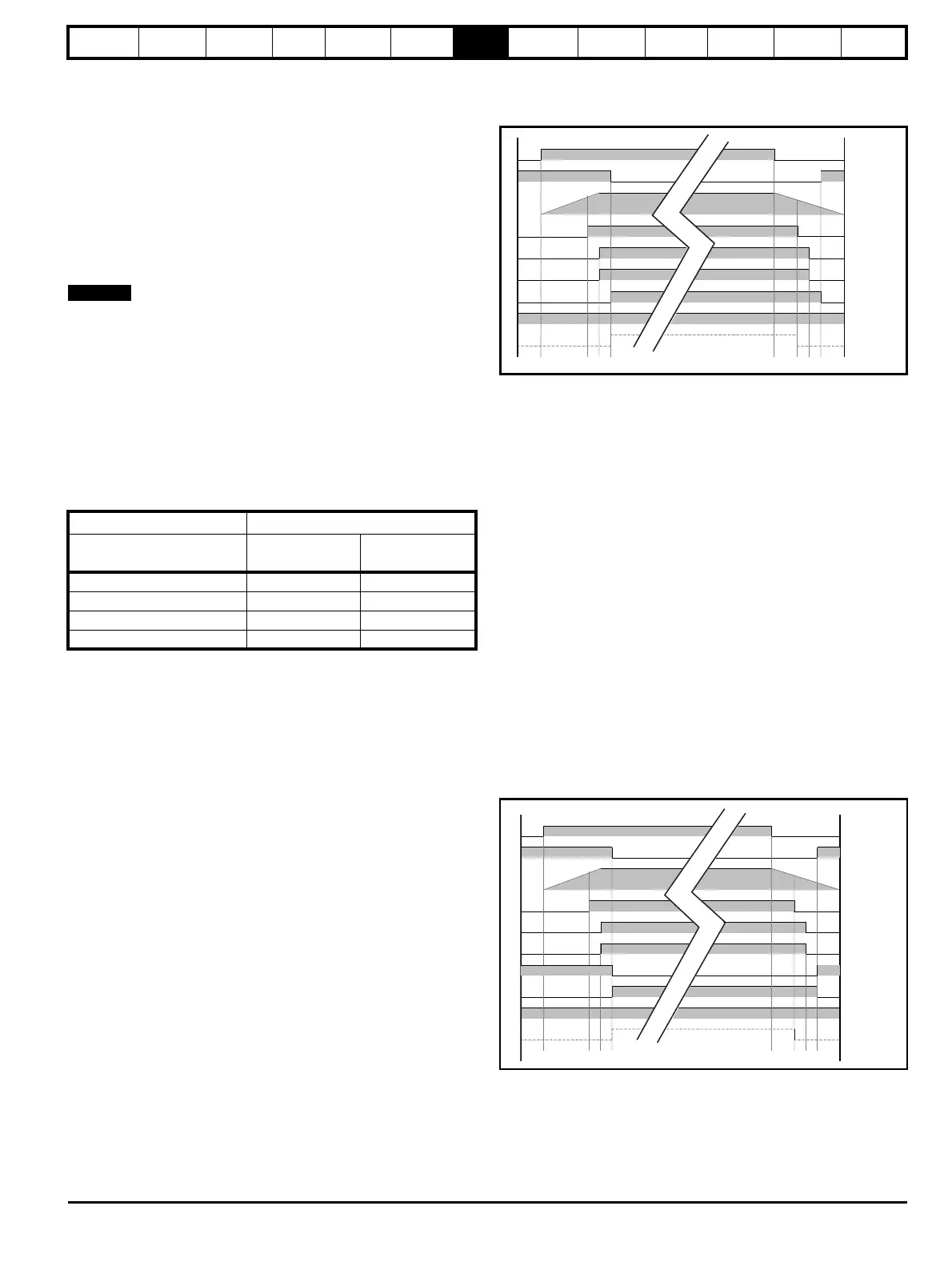

Figure 7-1 Single Regen: Single Motoring

1. K1 (main supply contactor / isolator / disconnect) is closed with

charging circuit active (K3 closed).

2. DC bus charges through the Regen drives Vac inputs L1, L2, L3

(charging circuit).

3. If the DC Bus > the UV threshold then K2 Regen drive main

contactor and Aux.2a are closed via Regen drives relay, control

terminals 41, 42.

4. K3 charging contactor is opened via K2 (Regen drive main contactor

as Aux.2b opens) and Aux.3 closes. The Regen drive enable, S1

can now be applied.

5. The Regen drive and motoring drives can be enabled (enable signal

from Regen drive to motoring drives active, control terminal 24).

6. K1 (main supply contactor / isolator / disconnect) is opened

removing power from the Regen system.

7. DC bus discharges to the UV threshold at which point the drive OK

relay becomes in-active. The Regen drives enable is removed.

The motoring drives enable signal from Regen drive becomes in-

active.

8. Regen drive main contactor, K2 is opened via the drive OK relay,

control terminals 41, 42. Aux.2a opens informing the drive that the

Regen drives main contactor K2 is open.

9. K3 charging contactor is closed and Aux.3 opens.

Power applied and power removed 400 V system

(refer to Figure 4-5 on page 44)

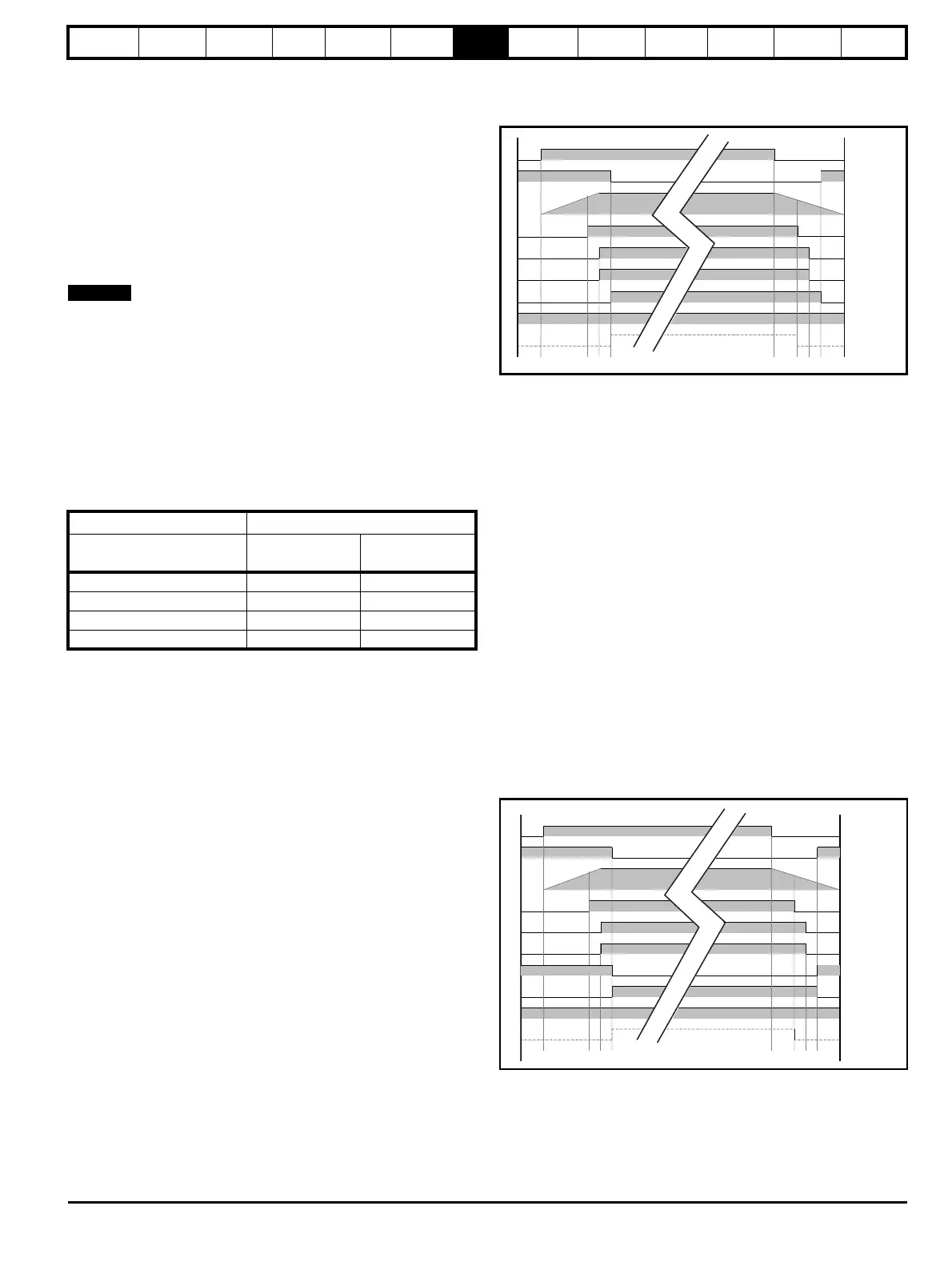

Figure 7-2 Single Regen: Multiple Motoring (Unidrive M Rectifier)

1. K1 (main supply contactor / isolator / disconnect) is closed with

charging circuit active (K3 closed).

2. DC bus charges through Unidrive M Rectifier (charging circuit).

3. If the DC Bus > the UV threshold then K2 Regen drive main

contactor and Aux.2a are closed via Regen drives relay, control

terminals 41, 42.

Voltage levels DC Bus voltage set-point

Supply voltage

Vac

Default

Vdc

Minimum

Vdc

200 350 350

400 700 700

575 835 835

690 1100 1100

K1

K3

Vdc

Drive OK

K2

Aux.3

Aux.2a

Aux.1

1 234 5 6 78

S1

9

K1

K3

Vdc

Drive OK

K2

Aux.3

Aux.2a

Aux.1

1 234 5 6 78

S1

9

Aux.2b

Loading...

Loading...