Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization

Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

144 Unidrive M Regen Design Guide

Issue Number: 1

The peak of the resulting transient is

Vdc = 191680 x Pd / (vll x Kp x Kc) Volts

and the time constant of the recovery is Kp / 30520 seconds.

where:

Pd is the transient change of power flow

vll is the line to line supply voltage

Kp = Voltage Controller Proportional Gain Kp (03.006)

Kc = Full Scale Current Kc (11.061)

For example, if Pd = 7.5 kW, vll = 400 V, Kp = 4000, Kc = 38.222 A then

Vdc = 23.5 V and the time constant is 131 ms.

In the example given there is a very rapid change of power flow.

The transient DC bus voltage change can be substantially reduced by

introducing a time constant into the power transient. For example a filter

could be included between the speed controller and current controller in

the motor drive with Current Reference Filter 1 Time Constant (04.012).

A time constant of 20 ms reduces the voltage transient by 25 % and a

time constant of 40 ms reduces the voltage transient by 50 %. In most

cases it is not desirable to reduce the performance of the motor drive,

and so as already mentioned the best solution is to use a power feed

forward term from the motor drive.

So far the discussion has been related to the DC bus voltage controller

gain, however, the controller provides the real current reference to the

Regen drive current controllers, and so the current controller gains affect

the response of the voltage controller. If the default voltage controller

gain is used and it is possible to obtain a stable response from the

current controllers with their default gains then the voltage controller

response will be stable. However, in some cases it will be necessary to

reduce the current controller gains to make these controllers stable,

in which case it is likely that the voltage controller gain will need to be

reduced to make this controller stable.

It is possible to disable the DC bus voltage controller by setting Voltage

Controller Proportional Gain Kp (03.006) to zero. This sets both the

proportional and integral gains to zero. Once the controller is disabled

the flow of power through the Regen drive can be defined using the

power input parameters (Power Input 1 (03.010), Power Input 2

(03.013), Power Input 3 (03.014), Power Input kW (03.018)) or

Active Current (04.002). This method of control can only be used if the

DC bus voltage is defined at a voltage above the level of the rectified AC

supply to the Regen drive by another system connected to the DC

terminals.

8.5 Power factor correction (Pr 04.008)

Reactive Current Reference (04.008) can be used to define a level of

reactive current other than the default value of zero, so that the Regen

drive can be made to produce or consume reactive power.

Reactive Current Reference (04.008) defines the level of reactive

current as a percentage of the Rated Current (05.007). Positive reactive

current produces a component of current flowing from the supply to the

Regen that lags the respective phase voltage, and negative reactive

current produces a component of current that leads the respective

voltage.

The variable maximum applied to Reactive Current Reference (04.008)

is used to ensure that the total current does not exceed the maximum

allowed. If the current limits are at their maximum values then no

reactive current is allowed and

VM_REGEN_REACTIVE_REFERENCE[MIN] = 0 and

VM_REGEN_REACTIVE_REFERENCE[MAX] = 0. As the Final Current

Limit (04.018) is reduced then more reactive current is allowed.

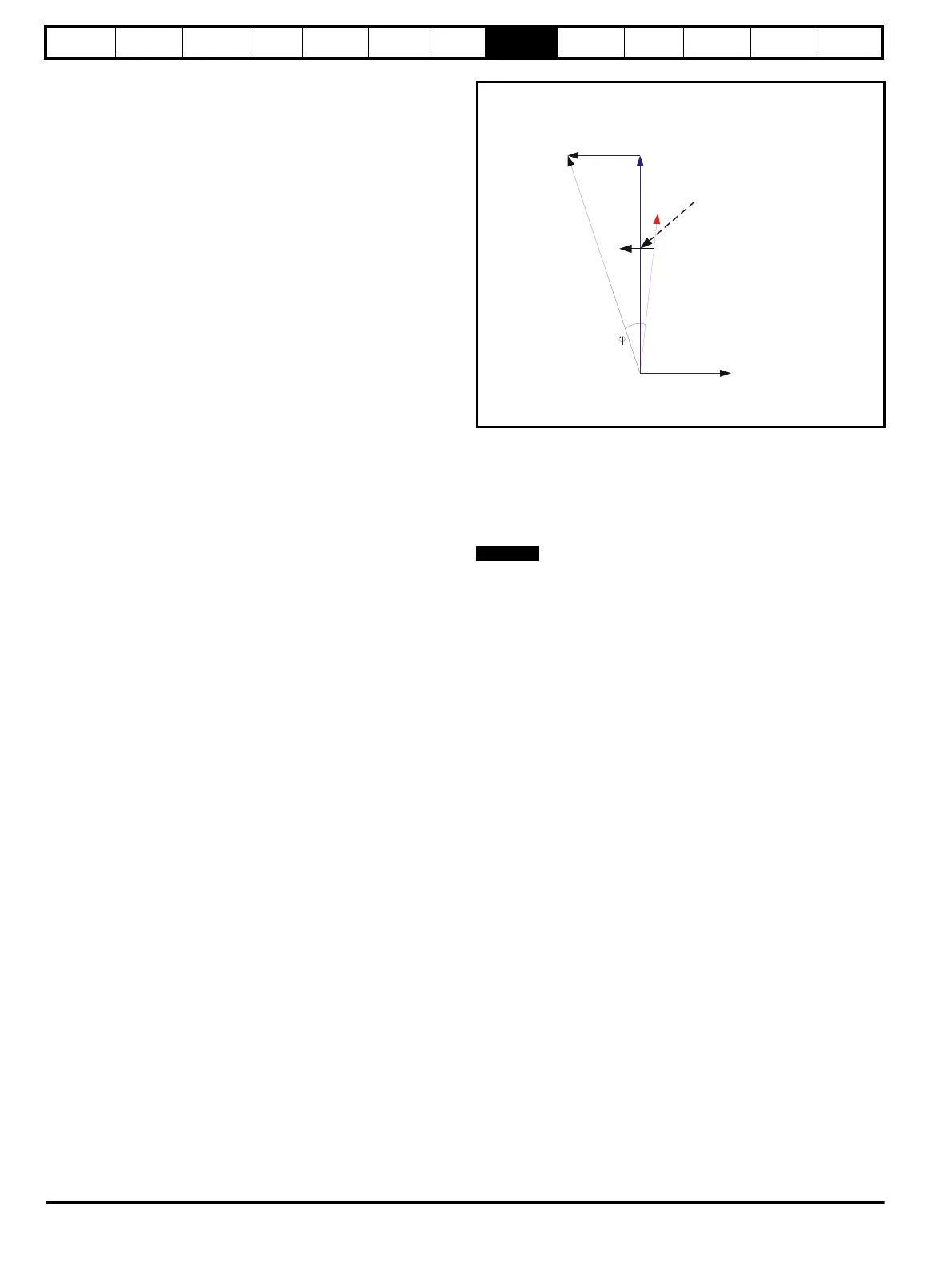

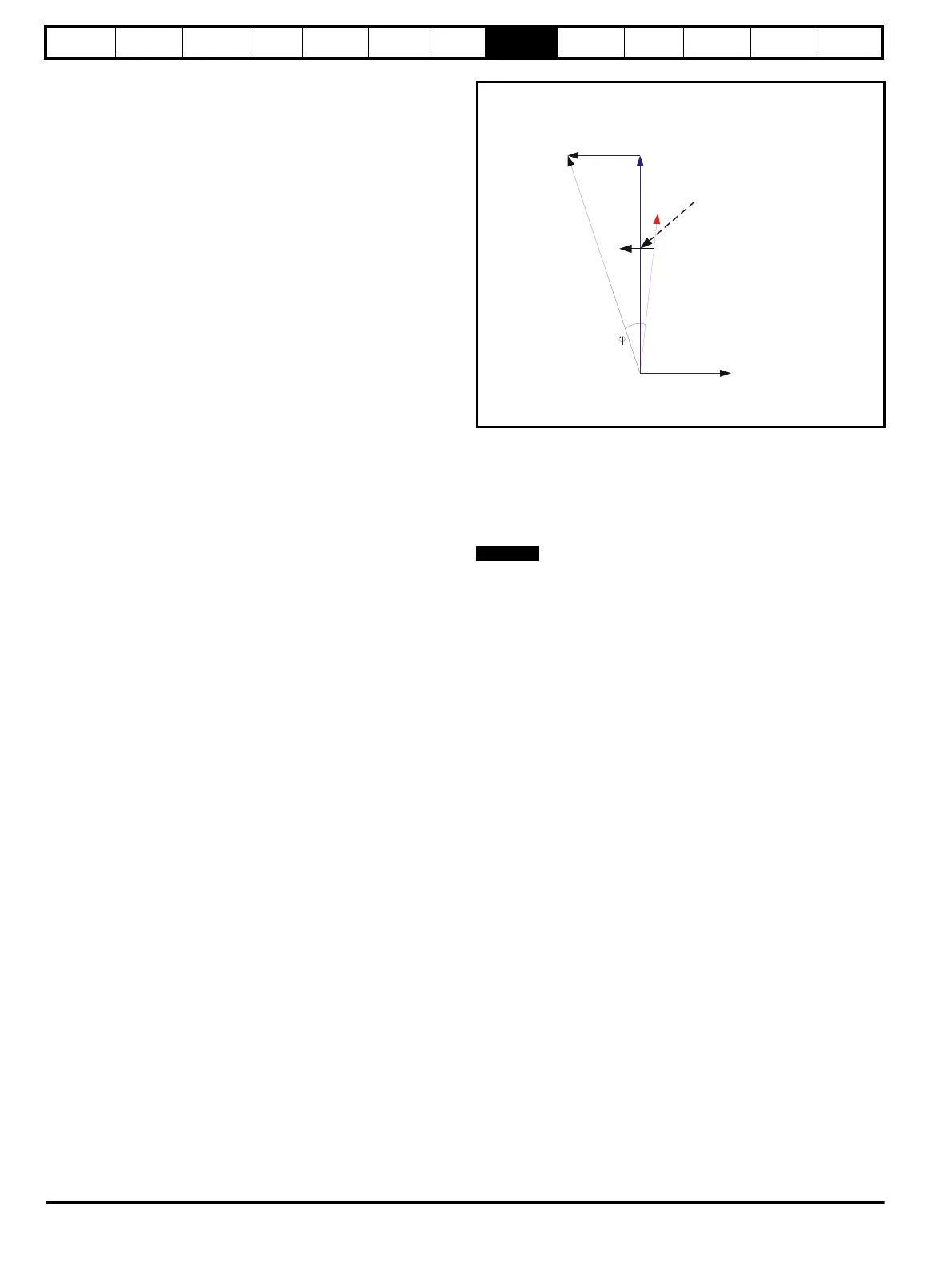

Figure 8-4 Power flow from supply to Regen drive

Vs Supply voltage

Vr Voltage at Regen drive terminals

Ir Total current at Regen drive terminals

JwLIr Voltage across Regen inductor

Power factor

The drive can control the reactive current / power, but not the real power.

8.6 Current trimming

A current feedback trimming routine runs before the Regen drive is

enabled to minimise offsets in the current feedback. If Current Trim

Mode (03.011) = 0 the current offset trim is only carried out once when

the drive comes out of the under voltage state and is not repeated unless

the supply is removed and re-applied. The current offset trim is only

carried out when the charge system is enabled (contactor open) as this

minimizes current flowing into the inverter terminals due to noise on the

supply that may disturb the current offset trimming.

Current Trim Mode (03.011) should be set to one if the current offset trim

is required each time when the Regen drive is enabled. To ensure that

the current offset trim is not disturbed by noise on the supply, the charge

system is enabled before the current offset trim and then disabled again

before the Regen drive goes into its active state. This causes the charge

system contactors to switch each time the Regen drive is enabled.

8.7 Voltage ramp time control (Pr 03.022)

When a Regen drive is enabled and has synchronized to the supply, the

DC bus voltage is at a level equal to the peak line to line voltage.

The voltage controller is then enabled and attempts to raise the DC bus

voltage to the set-point defined by Voltage Set Point (03.005).

The voltage reference is ramped up to the requried level at a rate

defined by Voltage Ramp Time (03.022) in V/ms. The default value of

1.0 V/ms ensures limited over-shoot when the DC bus voltage reaches

the required level. If a shorter synchronization time is required then the

ramp rate can be increased, however care must be taken to avoid over-

voltage trips particularly if a high level is used for the DC bus voltage set-

point. If a faster ramp rate and high set-point are required it may be

necessary the increase Voltage Controller Proportional Gain Kp (03.006)

to minimise over-shoot.

Voltage across

regen inductor

Isx

JwLIr

Vs

Vr

Ir

X axis componen

current

Power

factor

Modifying Ir directly

affects power factor

Loading...

Loading...