Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

76 Unidrive M Regen Design Guide

Issue Number: 4

5 Mechanical Installation

This chapter describes the installation of the Regen drive components.

Key features of this chapter include:

• Regen component dimensions

• Enclosure sizing and layout

• Enclosure ventilation

• Enclosure design with high ambient temperatures

Refer to the Mechanical Installation sections in the relevant Unidrive M

Power Installation Guide for drive mechanical information.

5.1 Safety information

5.2 Planning the installation

The following considerations must be made when planning the

installation:

5.2.1 Access

Access must be restricted to authorised personnel only. Safety

regulations which apply at the place of use must be complied with.

The IP (Ingress Protection) rating of the drive is installation dependent.

For further information, please refer to the relevant Unidrive M Power

Installation Guide.

5.2.2 Environmental protection

The drive must be protected from:

• moisture, including dripping water or spraying water and

condensation. An anti-condensation heater may be required, which

must be switched off when the drive is running.

• contamination with electrically conductive material.

• contamination with any form of dust which may restrict the fan, or

impair airflow over various components.

• temperature beyond the specified operating and storage ranges.

During installation it is recommended that the vents on the drive are

covered to prevent debris (e.g. wire off-cuts) from entering the drive.

5.2.3 Cooling

The heat produced by the drive / additional components must be

removed without its specified operating temperature being exceeded.

Note that a sealed enclosure gives much reduced cooling compared with

a ventilated one, and may need to be larger and/or use internal air

circulating fans.

For further information, please refer to section 5.5.2 Enclosure sizing on

page 102.

Through hole mounting is possible for all Unidrive M modules and the

Unidrive M Rectifier which can reduce cubicle heating and cooling

requirements. Refer to relevant Unidrive M Power Installation Guide or

Unidrive M Modular Installation Guide.

5.2.4 Electrical safety

The installation must be safe under normal and fault conditions.

Electrical installation instructions are given in Chapter 6 Electrical

Installation on page 105.

5.2.5 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided.

For installation in the USA, a NEMA 12 enclosure is suitable.

For installation outside the USA, the following (based on IEC 62109-1,

standard for PV inverters) is recommended.

Enclosure can be metal and/or polymeric, polymer must meet

requirements which can be summarized for larger enclosures as using

materials meeting at least UL 94 class 5VB at the point of minimum

thickness.

Air filter assemblies to be at least class V-2.

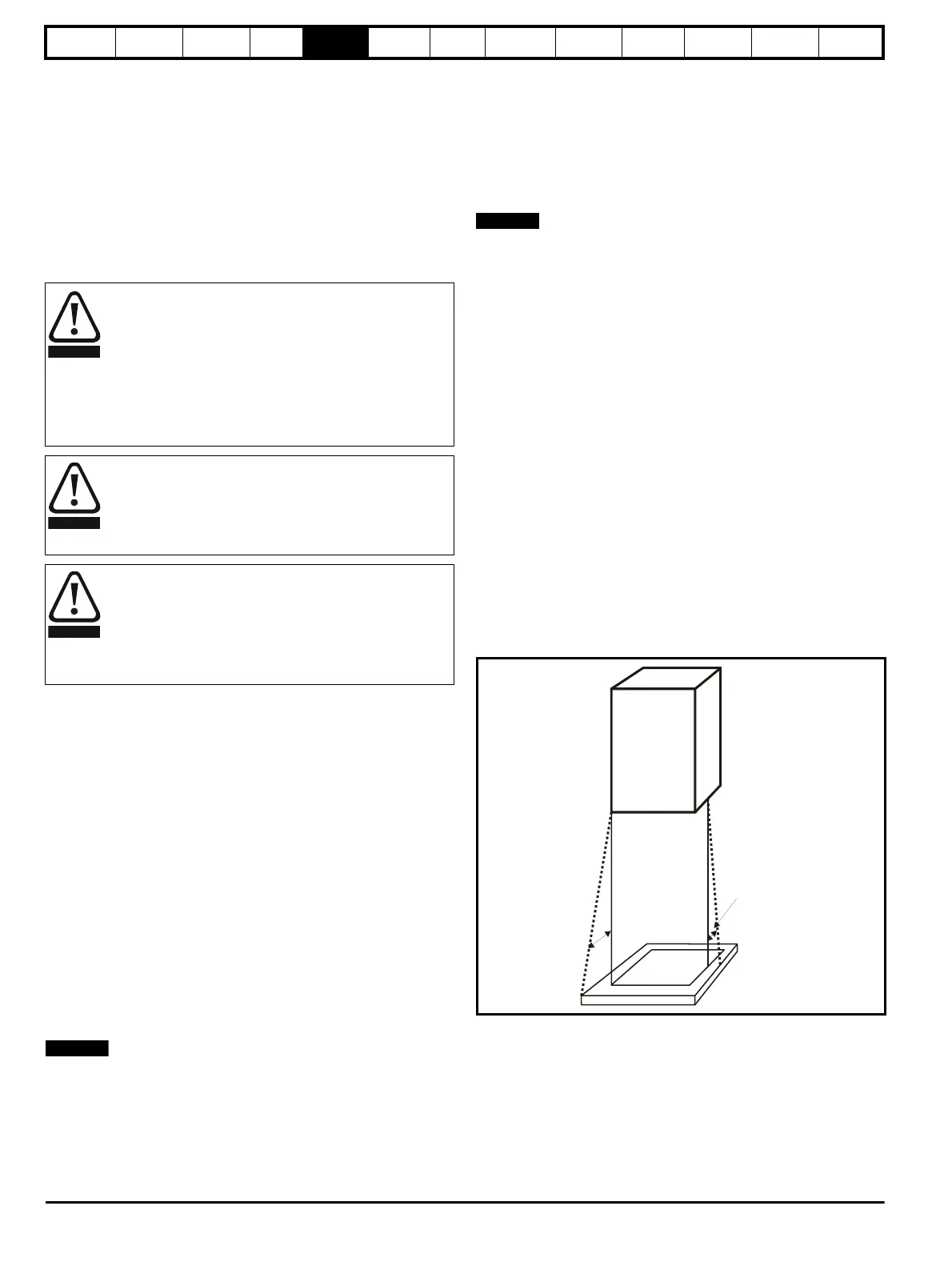

The location and size of the bottom shall cover the area shown in

Figure 5-1. Any part of the side which is within the area traced out by the

5° angle is also considered to be part of the bottom of the fire enclosure.

Figure 5-1 Fire enclosure bottom layout

The bottom, including the part of the side considered to be part of the

bottom, must be designed to prevent escape of burning material - either

by having no openings or by having a baffle construction.

This means that openings for cables etc. must be sealed with materials

meeting the 5VB requirement, or else have a baffle above.

See Figure 5-2 for acceptable baffle construction. This does not apply

for mounting in an enclosed electrical operating area (restricted access)

with concrete floor.

Follow the instructions

The mechanical and electrical installation instructions must

be adhered to. Any questions or doubt should be referred to

the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and

any external option unit, and the way in which they are

operated and maintained, comply with the requirements of

the Health and Safety at Work Act in the United Kingdom or

applicable legislation and regulations and codes of practice in

the country in which the equipment is used.

Competence of the installer

The drive must be installed by professional assemblers who

are familiar with the requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or

system complies with all the relevant laws in the country

where it is to be used.

Enclosure

The drive is intended to be mounted in an enclosure which

prevents access except by trained and authorized personnel,

and which prevents the ingress of contamination. It is

designed for use in an environment classified as pollution

degree 2 in accordance with IEC 60664-1. This means that

only dry, non-conducting contamination is acceptable.

Loading...

Loading...