Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

Unidrive M Regen Design Guide 11

Issue Number: 4

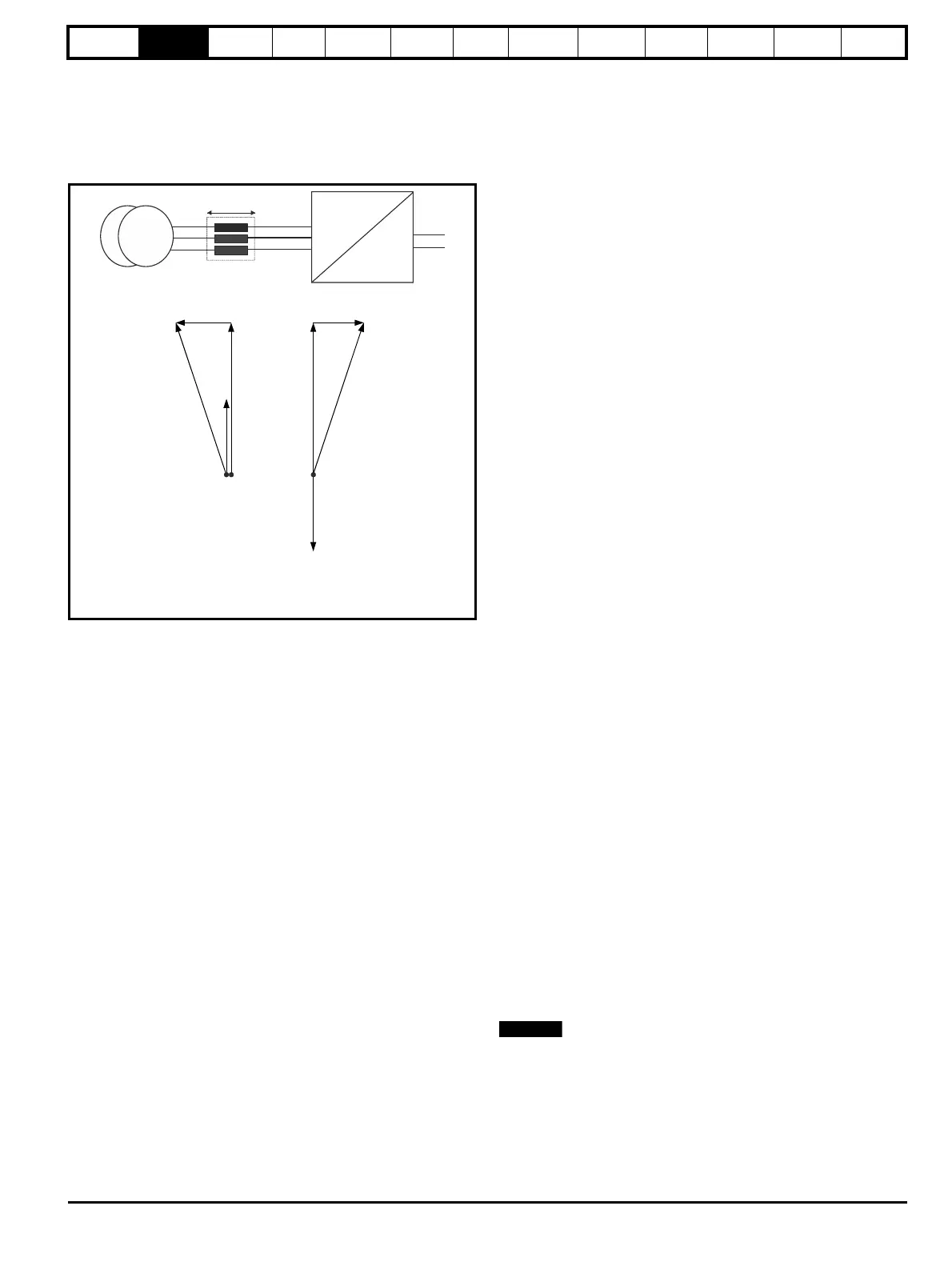

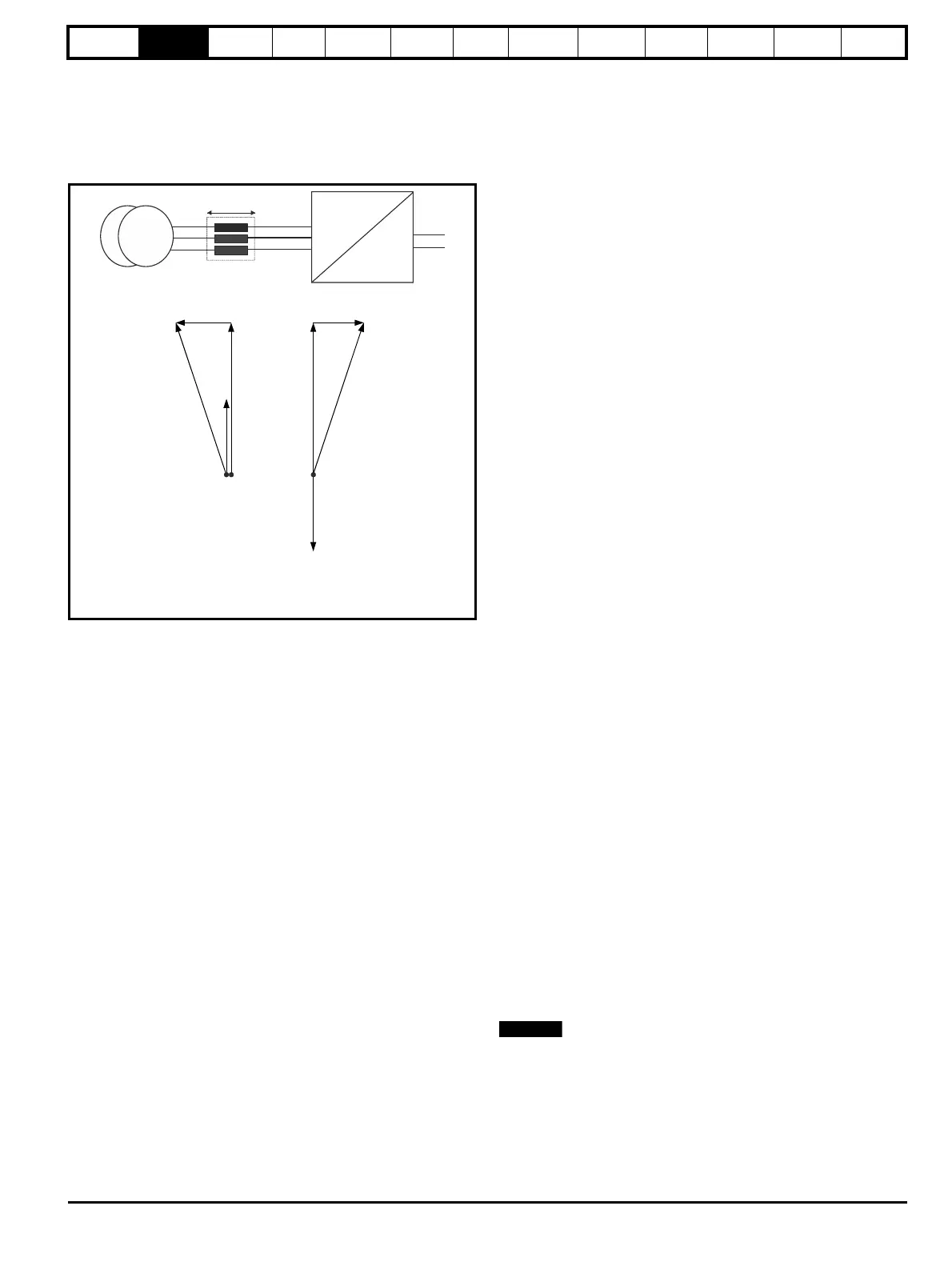

2.4 Power flow

The following phasor diagram illustrates the relationship between the

supply voltage and the Regen drive voltage. The angle between the two

voltage vectors is approximately 5° at full load, this can result in a near

unity power factor of 0.996, depending on the grid supply conditions.

Figure 2-1

The direction of the power flow can be changed relative to the supply

voltage, by making small changes to the Regen drives output voltage

and phase.

2.5 Synchronization

The synchronization of the Regen drive to the supply does not require

additional hardware. The space vector modulator within the Regen drive

represents the angle and magnitude of the AC supply at all times. This

however is not the case when the AC supply is first connected or when

the Regen drive is disabled.

Unless some form of synchronization is carried out the current

controllers will start with values of zero resulting in zero volts being

applied to the inverter output terminals. The phase locked loop (PLL)

would also start with zero and so would not lock onto the supply.

To overcome these problems the following information must be obtained

before the Regen drive attempts to start:

1. The mains supply voltage vector magnitude

2. The angle of the supply voltage vector

3. The frequency of the supply

These values are obtained by carrying out a synchronization on enable

• The first stage of the pre-start tests is to measure the initial DC bus

voltage, which by default, is assumed to be equal to the peak line-to-

line voltage of the supply.

• The second stage of the pre-start test is to apply two short pulses of

zero volts at the converter input. These pulses must be short enough

so that the peak current is less than the over current trip level of the

converter. The time between the pulses must also be long enough

so that the current built up in the input inductors during the first pulse

has decayed to a low level before the second pulse is applied.

These are used to calculate the instantaneous angle of the supply

voltage vector during the first test pulse. The second test pulse is

then applied at time Td later to allow the supply frequency to be

calculated.

At this stage the supply inductance is also calculated.

• Once the synchronization is complete the phase locked loop (PLL) is

set-up. At this point the whole control system could be started and

should operate without any large transients.

• To improve the robustness of the start-up phase a further short test

pulse voltage vector, with the same magnitude and phase as the

estimated supply voltage vector is applied. This is to detect

measurement errors that could have occurred because of supply

distortion present during the pre-start tests. The Regen drive may

not synchronize to the supply if the grid voltage is highly distorted.

2.6 Current trimming

A current feedback trimming routine runs before the drive is enabled to

minimise offsets in the current feedback. This feature can be user

configured, for more details refer to section 8.6 Current trimming on

page 144.

2.7 Regen system configurations

The Regen drive has been designed to provide a regulated DC supply to

other motoring drives. The Regen drive gives bi-directional power flow

with sinusoidal currents and a near unity power factor.

Following are the possible configurations for Unidrive M Regen:

• Single Regen, single motoring (Figure 4-4 on page 42).

• Single Regen, multiple motoring using a Unidrive M Rectifier

(Figure 4-5 on page 44).

• Single Regen, multiple motoring using an external softstart resistor

(Figure 4-6 on page 46).

• Multiple Regen, multiple motoring using a Unidrive M Rectifier

(Figure 4-7 on page 48).

• Regen drive as brake resistor replacement (Figure 4-8 on page 52).

Refer to section 3.3 Ratings on page 17, for the Regen drive ratings.

The sizing of a Regen system must take into account the following

factors:

• Line voltage

• Motor rated current, rated voltage and power factor

• Maximum load power and overload conditions

In general, when designing a Regen system, equal Regen and motoring

drive rated currents will work correctly. However, care must be taken to

ensure that under worst case supply conditions the Regen drive is able

to supply or absorb all the required power. In multi-drive configurations,

the Regen drive must be of a sufficient size to supply the net peak power

demanded by the combined load of all the motoring drives and total

system losses.

If the Regen drive is unable to supply the full power required by the

motoring drive, the DC bus voltage will drop and in severe cases may

lose synchronization with the mains and trip. If the Regen drive is unable

to regenerate the full power from the motoring drive on the DC bus, then

the Regen and motoring drive(s) will trip on over-voltage.

2.8 Regen drive system types

2.8.1 Single Regen, single motoring system

Figure 2-2 shows a typical layout for a standard Regen system

consisting of a single Regen drive and single motoring drive. In this

configuration the Regen drive is supplying the motoring drive and

passing the regenerative energy back to the mains supply.

The power up connections to L1, L2, L3 of the Regen drive are only

made during power-up. Once both drives are powered up, this is

switched out and the main Regen supply switched in. The auxiliary on

the charging circuit to the Regen drive’s L1, L2, L3 connections for

power up must be closed (charging supply removed) before the Regen

drive can be enabled.

r

V

r

V

r

r

V

s

I

I

Power flow

from supply

Power flow

back to supply

V Supply voltage

s

V Voltage at line terminals of Regen drive

r

j LI Voltage across Regen inductor

r

I Current at line terminals of Regen drive

r

AC

DC

U

V

W

+DC

-DC

I

r

V

s

VAC

Supply

V

r

JLI

r

jLI

r

jLI

r

V

s

Loading...

Loading...