Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization

Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

142 Unidrive M Regen Design Guide

Issue Number: 1

8 Optimization

The following section covers optimization of the Regen system which can be carried out by the user.

8.1 Power feed-forward compensation (Pr 03.010)

Power feed-forward compensation can be used to reduce the transient DC bus voltages produced when a fast load transient occurs on the motoring

drives connected to the Regen drive.

If Power Output (07.033) from a motor drive is routed to an analog output with unity scaling it will produce full scale output when the power is equal to

3 x (VM_DC_VOLTAGE[MAX] / 22) x Full Scale Current Kc (11.061). If this signal is connected to an analog input on the Regen drive, the input is

routed to Power Input 1 (03.010) and Power Input 1 Scaling (03.015) is set to the ratio of the current scaling values for the motor drive and Regen

drives (i.e. Motor drive Full Scale Current Kc (11.061) / Regen drive Full Scale Current Kc (11.061)) then the correct power feed-forward term will be

provided. The default value for Power Input 1 Scaling (03.015) is 1.000, and so unless the Regen and motor drives are the same size this parameter

will need to be adjusted.

Up to 3 motor drives connected to the Regen drive DC terminals can use this system to provide power feed-forward as each of the power inputs are

summed to give the final power feed-forward term. (It should be noted that a maximum of two analog inputs are provided on the drive with 250 µs

update rate. If the third input is used the update rate is 4 ms, and so this should only be used for a motor drive with limited dynamic performance.)

If more motor drives are connected to the DC terminals of the Regen drive, or a digital power feed-forward system is required, then Power Input kW

(03.018) should be used. The power in kW can be transferred from each motor drive using fast synchronous communications to an application

module in the Regen drive. The total power in kW should be calculated by the applications module and then written to the Power Input kW (03.018).

For the power feed-forward to be effective data should be transferred every 250 µs with the minimum delay (i.e. 500 µs) and the total power written to

Power Input kW (03.018) every 250 µs.

It should be noted that the polarity of all the power feed-forward parameters is that positive values cause power to flow from the supply and negative

values cause power to flow into the supply.

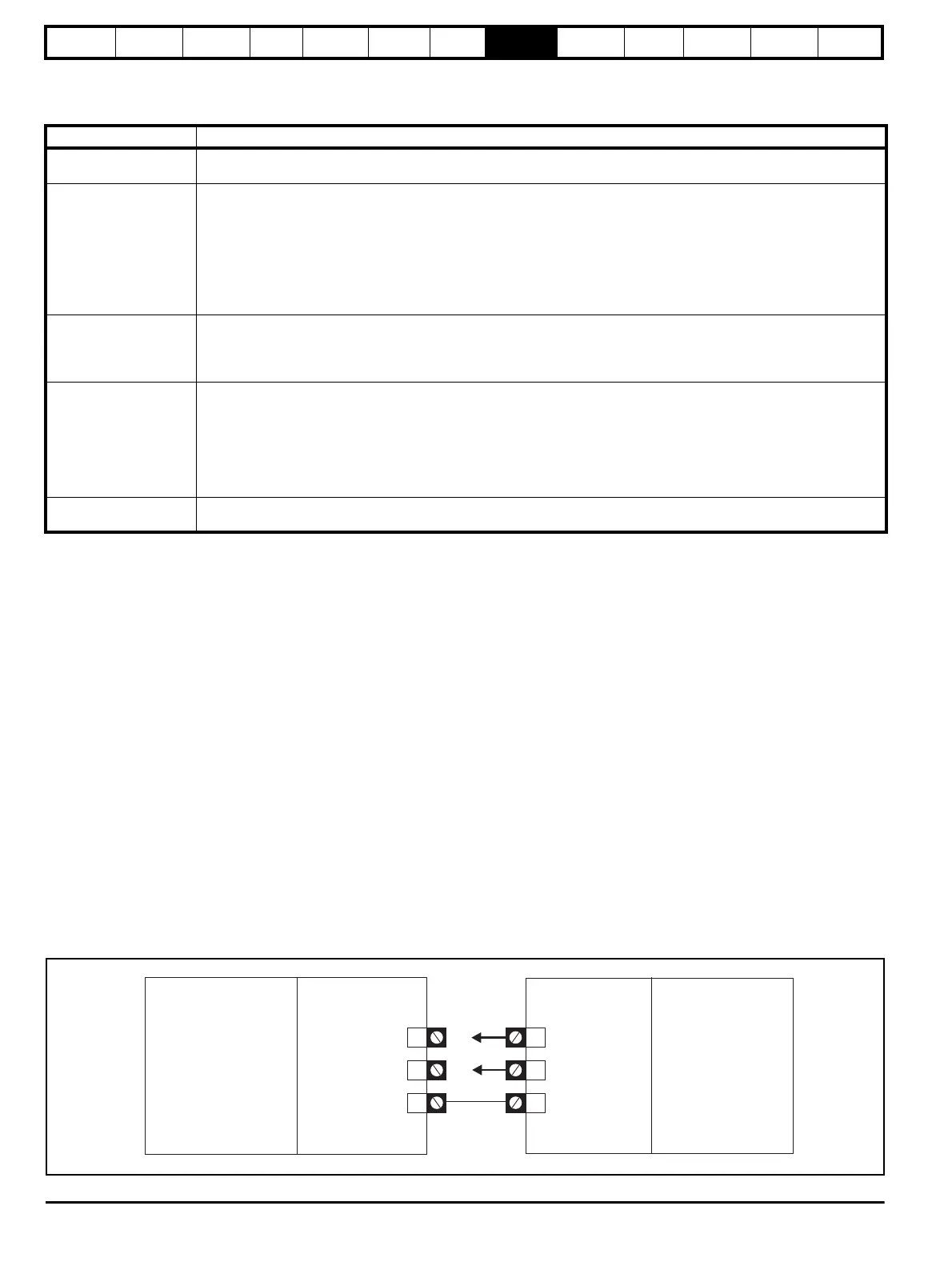

Figure 8-1 shows the Regen drives analog inputs and motoring drives analog outputs which can be used to pass Pr 05.003 (motoring drive output

power) to the Regen drive which is then used for the power feed-forward.

Only one analog output from the motoring drive and one analog input to the Regen drive is required to configure the power feed-forward term.

Figure 8-1 Power Feed-forward configurations

Feature Detail

Power feed-forward

Power feed-forward can be used to reduce fast transient DC bus voltage effects produced by transient load conditions on

motoring drives mainly in Dynamic applications where spurious over-voltage and/or over-current trips are experienced.

Voltage controller gain

The voltage controller gain can be implemented to overcome instability in the DC voltage on the common DC bus in the

following conditions,

• A brake resistor replacement system where the ratio between Regen brake drive and motoring drive(s) DC bus

capacitance is large

• With multiple motoring drive(s) where the ratio between the Regen drive(s) and motor drive(s) DC bus capacitance is

large.

Ensure the voltage controller gain is not increased too high as this can also introduce excessive ripple and instability on

the DC bus.

Current loop gains

The current loop gains can be optimized to overcome spurious over-current trips during either synchronization to the

power supply, or during operation.

The default gain settings are sufficient for most applications however these can be modified with the proportional (Kp)

being the most critical for stability.

Power factor correction

This does not optimize the Regen system but improves the power factor of the supply that is connected to the Regen

system.

• Will introduce cost saving (electricity bill), compensate for inductive loads on the same supply, and overcome voltage

drops due to “soft supplies”.

• A separate power factor correction unit may not be required.

• The symmetrical current limit must be below its maximum in order for power factor correction to work (therefore may

be limited due to Regen drive size).

Voltage ramp time

The ramp time for the DC bus voltage to reach the Voltage Set Point (03.005) can be controlled by Voltage Ramp Time

(03.022) which allows a shorter synchronization time if required.

Analog input 2

7. 14Destination Pr 00

=3.1000

Scaling Pr 7. 1200

Analog input 3

7. 18Destination Pr 00

=3.1000

Scaling Pr 7. 1600

Regen drive

Analog I/P 2

Pr set-up

Analog I/P 3

0V common

Pr set-up

Analog O/P 1

Analog O/P 2

0V common

Motoring drive

Analog output 1

7. 19Source Pr =00

5.0 300

Analog output 2

7. 22Source Pr =00

005.0 3

7

8

11

9

10

11

Loading...

Loading...