Safety

information

Introduction

Product

Information

System

design

Mechanical

Installation

Electrical

Installation

Getting

started

Optimization

Parameters

Technical

data

Component

sizing

Diagnostics

UL

Information

Unidrive M Regen Design Guide 143

Issue Number: 1

8.2 Regen controllers

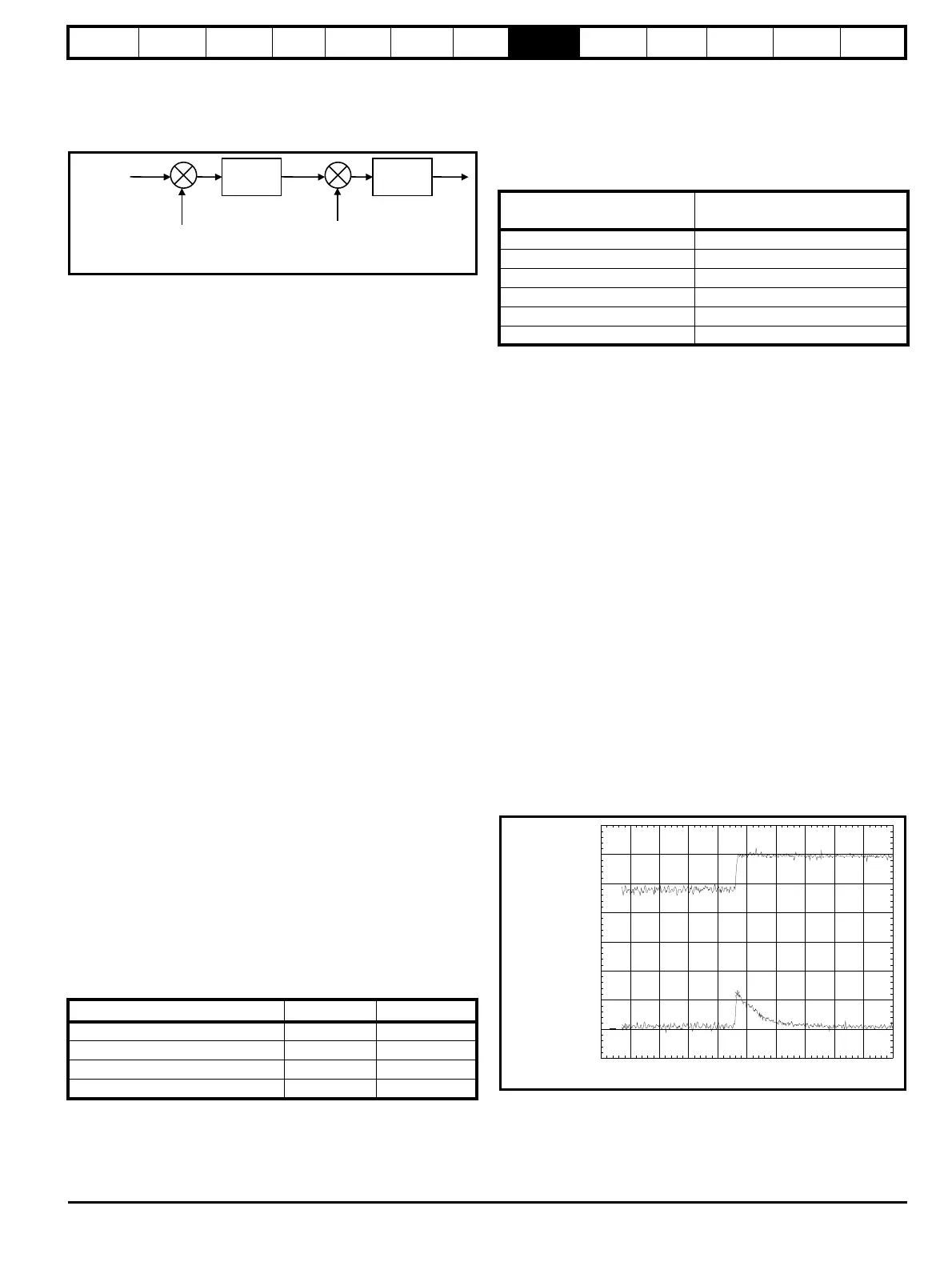

The Regen drive uses a DC bus voltage controller with inner current

controllers as shown in Figure 8-2:

Figure 8-2 Regen controllers

The gains of the voltage and current controllers affect the stability of the

Regen system, with incorrect settings resulting in over-voltage or over-

current trips.

8.3 Current loop gains

The defaults current loop gains (Kp, Pr 04.013 and Ki, Pr 04.014) are

suitable for most standard Regen systems. However if the input

inductance is significantly higher the proportional gain may need to be

adjusted as described following.

The most critical parameter for stability is the current controller

proportional gain, Pr 04.013. The required value for this is dependent

upon the Regen drives input inductance. If the inductance of the supply

is a significant proportion of the recommended Regen inductor

i.e. 60/I

DR

mH per phase,

Where:

I

DR

is the drive rated current

then the proportional gain may need to be increased.

The supply inductance is likely to be negligible compared to the Regen

inductor value with small drives, but is likely to be significant with larger

drives. The proportional gain, Pr 04.013 should be adjusted as

described following using the total inductance per phase.

The proportional gain, Pr 04.013 can be set by the user so that

Pr 04.013 = Kp = (L / T) x (I

fs

/ V

fs

) x (256 / 5)

Where:

T is the sample time of the current controllers. The drive compensates

for any change of sample time, and so it should be assumed that the

sample time is equivalent to the lowest sample rate of 167 s.

L is the total input inductance.

I

fs

is the peak full-scale current feedback

I

fs

= Full Scale Current Kc (11.061) x 2

Vfs is the maximum DC bus voltage.

Therefore:

Pr

04.013

= Kp = (L / 167 s) x (Kc x 2 / Vfs) x (256 / 5)

= K x L x Kc

Where:

K = [2 / (Vfs x 167 s)] x (256 / 5)

There is one value of the scaling factor K for each drive voltage rating as

shown in the table below.

This set-up will give a step response with minimum overshoot after a

step change of current reference. The approximate performance of the

current controllers will be as given below. The proportional gain can be

increased by a factor of 1.5 giving a similar increase in bandwidth,

however, this gives a step response with approximately 12.5 %

overshoot.

Table 8-1 Current loop sample times

As previously detailed the current controller integral gain, Pr 04.014 is

not so critical with the recommended value being the default setting.

8.4 Voltage controller proportional gain

Kp (Pr 03.006)

The DC bus voltage is controlled by a PI controller, which provides the

reference for the real component of current from the inverter terminals to

the supply. The power input parameters (Power Input 1 (03.010),

Power Input 2 (03.013), Power Input 3 (03.014) or Power Input kW

(03.018)) are provided to give a power feed forward term, at the output

of the PI controller, from the motor drives connected to the DC bus.

If possible the power feed forwards should be used so that the PI

controller is simply providing a trim to the DC bus voltage. In most cases

the default voltage controller gains can be used, however the effect of

the gains and the response of the voltage controller is discussed below.

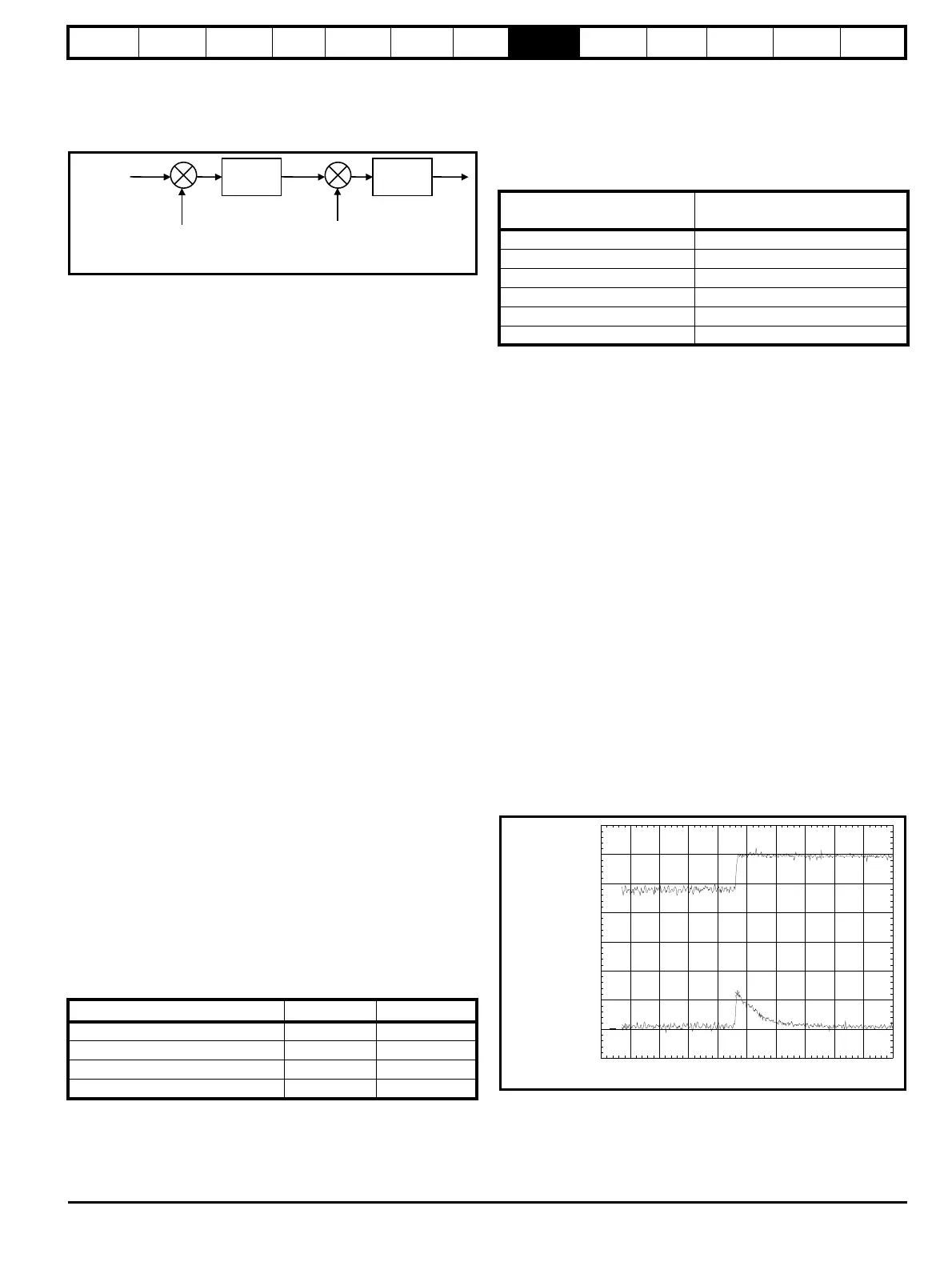

For the purpose of analyzing the voltage controller response it is

assumed that a power feed-forward term is not provided. If the power

flow from the DC bus is increased (i.e. motor is accelerated by a motor

drive connected to the DC bus) the DC bus voltage will fall, but the

minimum level will be limited to just below the peak rectified level of the

supply provided the maximum rating of the unit is not exceeded. If the

power flow to the DC bus is increased (i.e. motor is decelerated by a

motor drive connected to the DC bus) the DC bus voltage will rise. If the

peak of the DC bus voltage reaches the over voltage level the Regen

drive will trip. A rapid transient where power into the DC bus is increased

is shown below in Figure 8-3.

Figure 8-3 DC Bus transient

The example shown is for a very rapid load change where the torque

reference of the motor drive has been changed instantly from one value

to another.

Drive voltage rating (11.033) Vfs K

200 V 415 V 1045

400 V 830 V 522

575 V 990 V 438

690 V 1190 V 364

Voltage

controller

Current

controllers

-

-

DC bus

voltage

feedback

Current

feedback

Pr DC03.005

bus voltage

set point

Switching frequency kHz

Current control sample time (T)

s

3 167

4 125

683

8 62.5

12 83

16 62.5

Regen unit

DC bus voltage

Real current

100ms/div

Loading...

Loading...