WHEEL DRIVE SYSTEM 71Service Manual – Advenger, 2800ST, 3800ST, BR 755, BR 855

Inspecting/Replacing the Drive Wheel Assembly Carbon Brushes

IMPORTANT!

To remove/replace/inspect the Carbon Brushes, observe the following:

1 The motor must come off of the machine.

2 The motor assembly must be kept vertical while being disassembled to prevent loss of gear oil.

WARNING!

Park the machine on a dry at surface, turn the main key

switch (J) to the Off position and disconnect the battery

pack at the red Anderson connectors inside the battery

compartment.

1 Follow the instructions in “Replacing the Drive Wheel

Assembly”.

2 Place the motor assembly upright, motor side up, as shown.

CAUTION!

To prevent gear oil from draining from the gearbox,

disassemble the motor with the Drive Wheel assembly in a

vertical position. If some oil is lost, drain completely and rell

the oil as indicated at the bottom of the page.

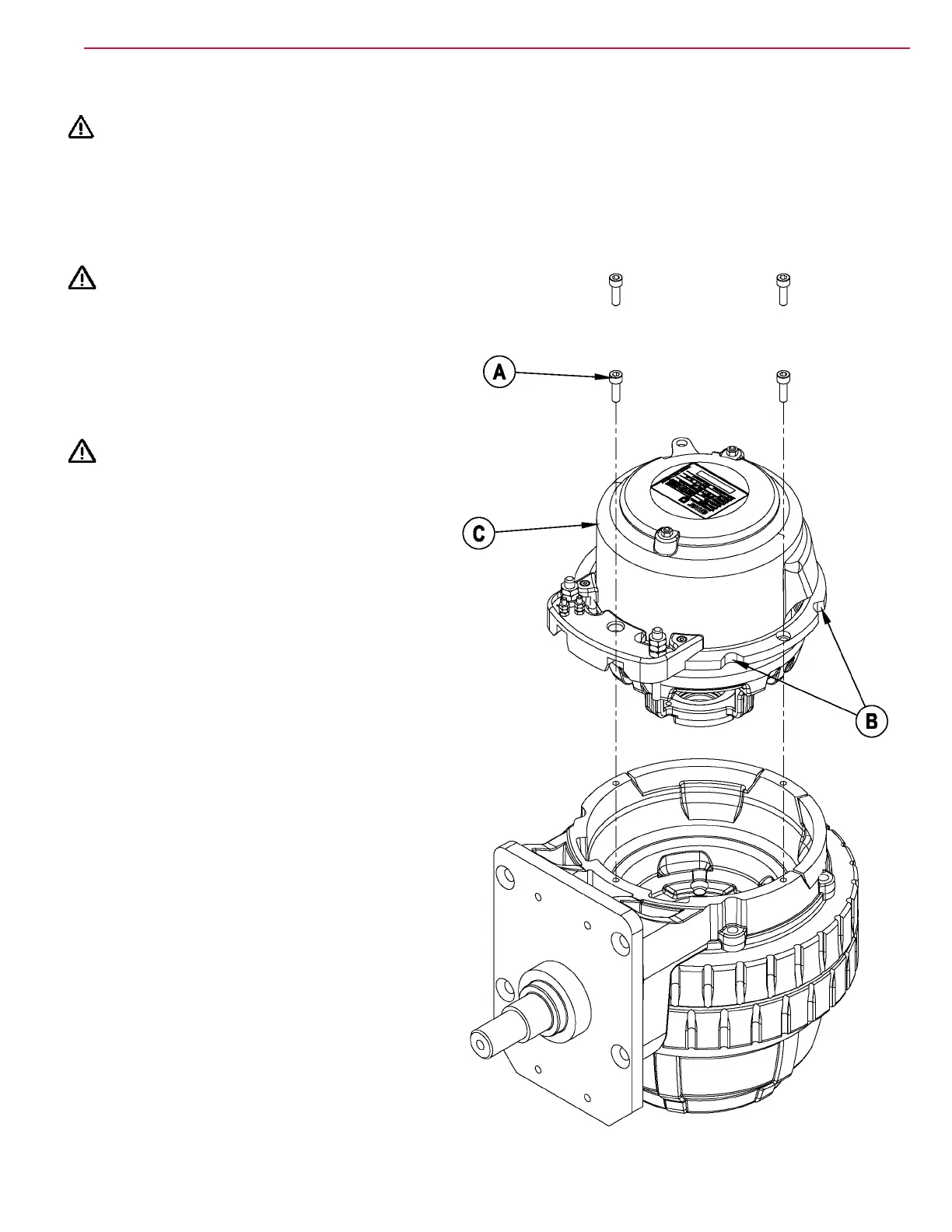

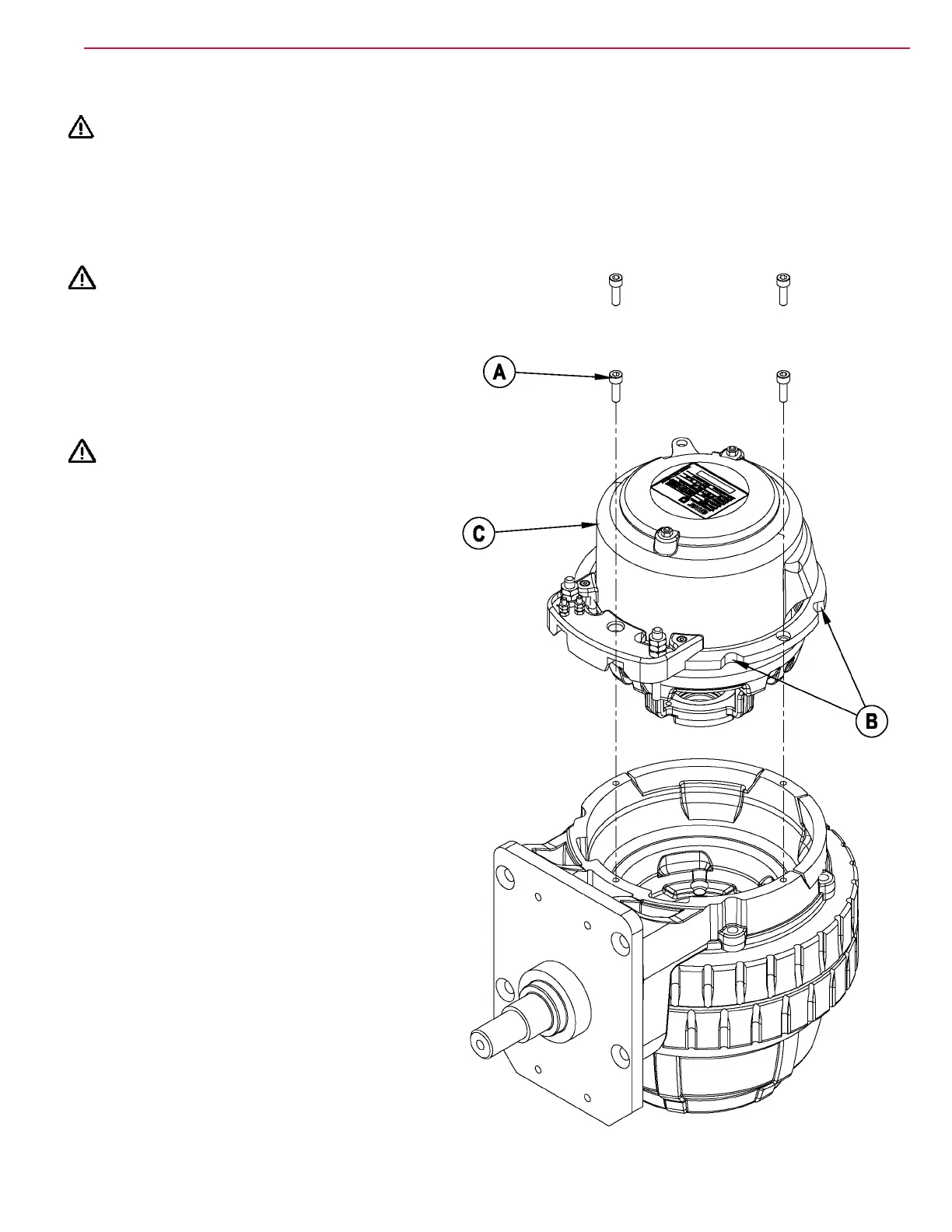

3 See Figure 37. Remove the four metric socket head cap

screws (A) securing the electric motor to the casting.

4 Use a hard piece of wood or a brass drift punch to tap the

motor mounting ange (3 notched locations (B)) to loosen.

5 Grip the motor/brake end bell and pull the motor (C) up and out

of its housing.

6 Inspect the 4 carbon brushes and springs. A new carbon brush

measures 3/4”. If less than 1/4”, replace.

7 Clean the foam lters, and blow out the motor.

8 If gear oil has been lost, drain and replace with 4.5856 oz (130

g) of Mobilgear 600 XP 150 or AGIP BLASIA 150 gear oil.

FIGURE 37

Loading...

Loading...