3-16

CHAPTER 3 REPAIR PROCEDURES

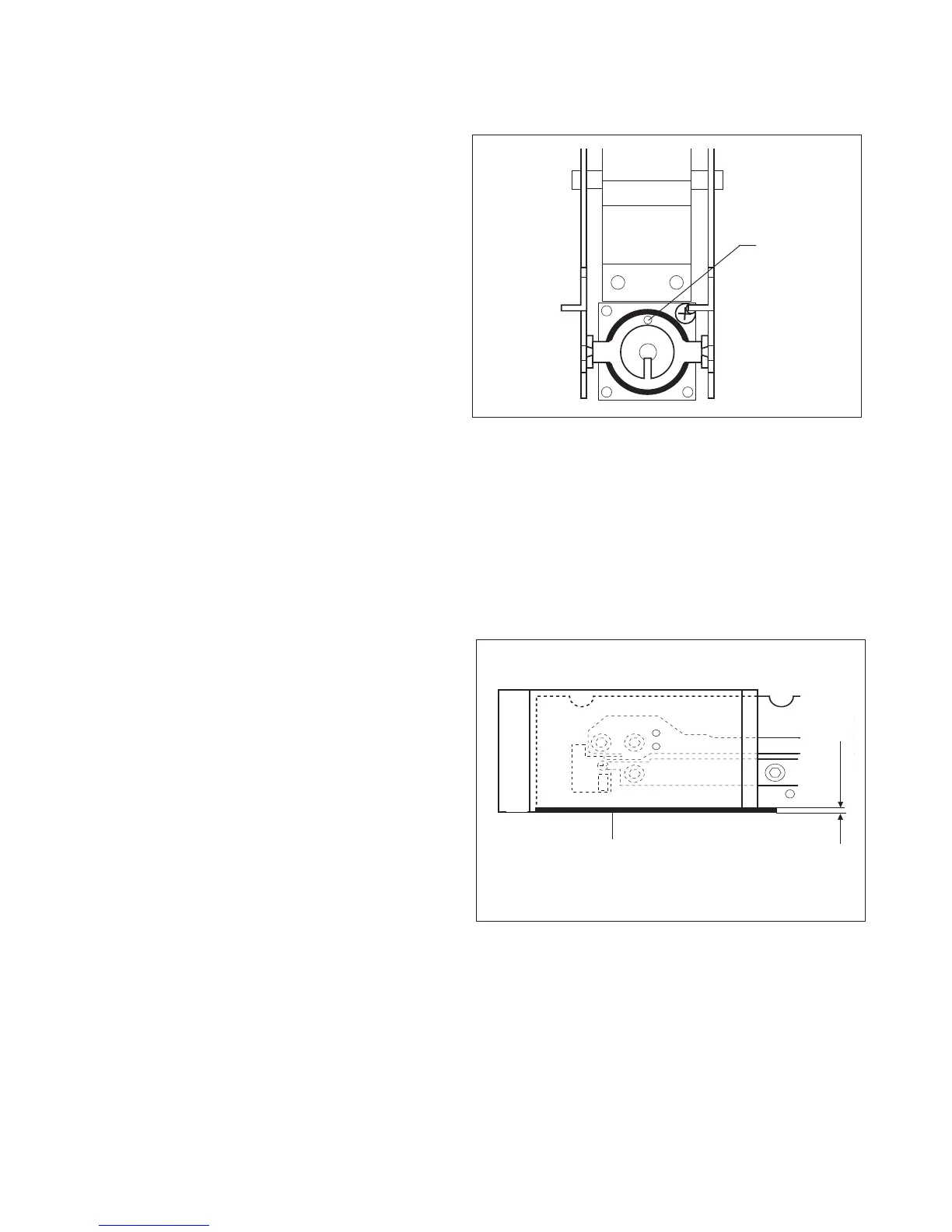

3.1.24 Installing the Force Coil Lever Assembly in Monoblock for High Capacity Top

Loader Balance

Figure 3-22. Force Coil Lever Installation.

1.Place Lever in designated position: check that

the aluminum sleeves are properly positioned.

2.Turn back height adjustment screw to original

position.

3.Insert Centering Pins in holes provided.

4.Insert Lever fastener screws and tighten care-

fully. Ensure that the Lever remains in the

middle at the front.

5.Mount Cover Plate (align at centering pin (g)).

6. Place Position Sensor on the Coil housing.

7.Insert the three screws and tighten with the

nuts.

8.Adjust Position Sensor as described in 3.1.27.

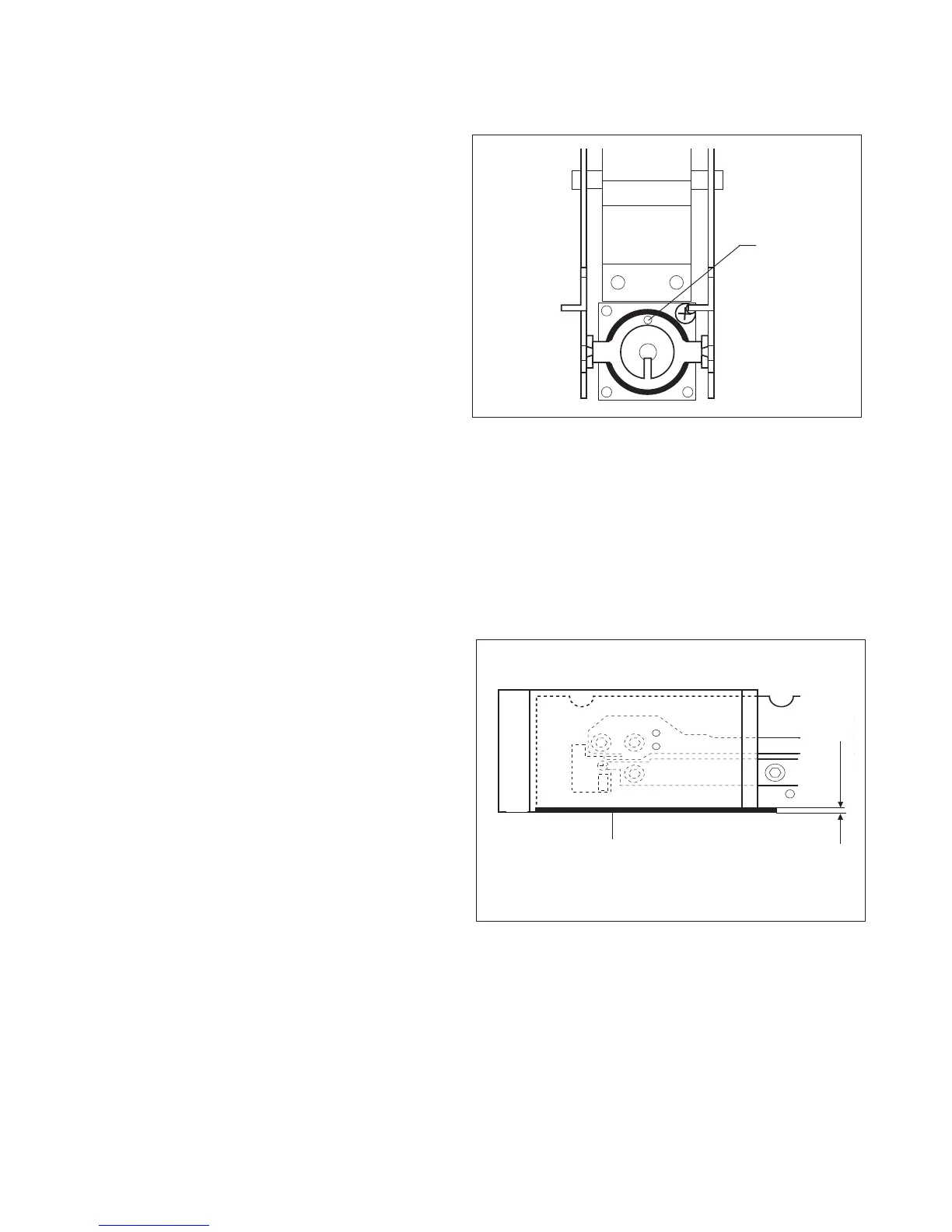

3.1.25 Installing Monoblock and Assembling Position Sensor for High Capacity Top

Loader Balance

1.Place Monoblock and formed chassis turned

by 180 degrees on a flat and clean bench

surface.

2.Screw Monoblock to formed chassis. Ensure

top edge of formed chassis is flush with the top

of the Monoblock. See Figure 3-23.

NOTE:

Tightening torque: 4.0 Nm.

3.Install Calibration Motor (eccentric in top posi-

tion) and Calibration Bracket. During installa-

tion, ensure that there is sufficient play be-

tween the eccentric of the Motor and the Cali-

bration Bracket.

4.Ensure that the Calibration Motor is in the top

position, then insert Calibration weights. Align

Calibration Weight Holders parallel with the

edge of the frame profile and screw firmly so

that a slight pressure causes the Holders to rest

on the Weights.

Figure 3-23. Installation Monoblock and

Position Sensor.

g

i

h

0.5 mm

Loading...

Loading...