121

Wiring CP1H CPU Units Section 3-4

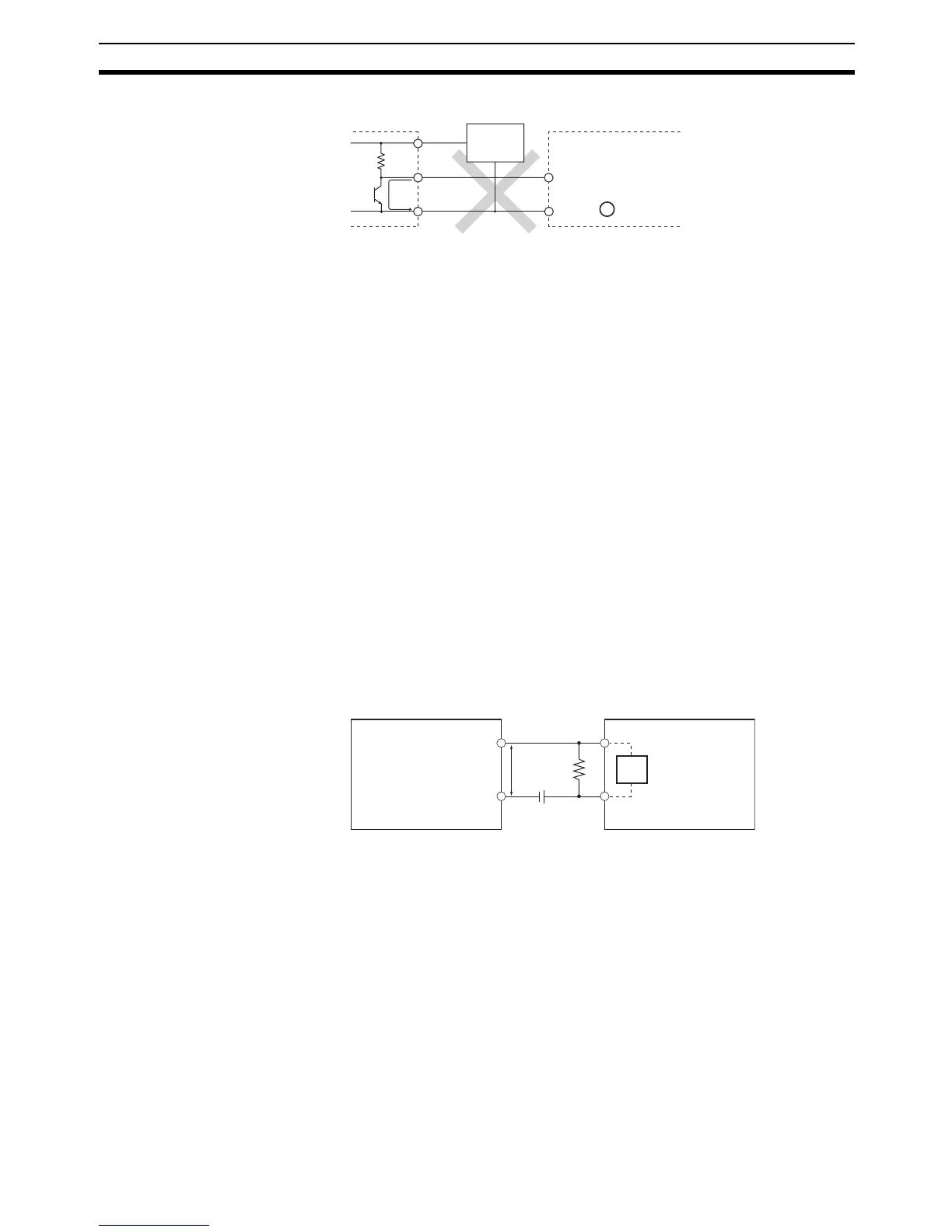

• The circuit below should not be used for I/O devices with a voltage output.

Precautions when

Connecting a Two-wire DC

Sensor

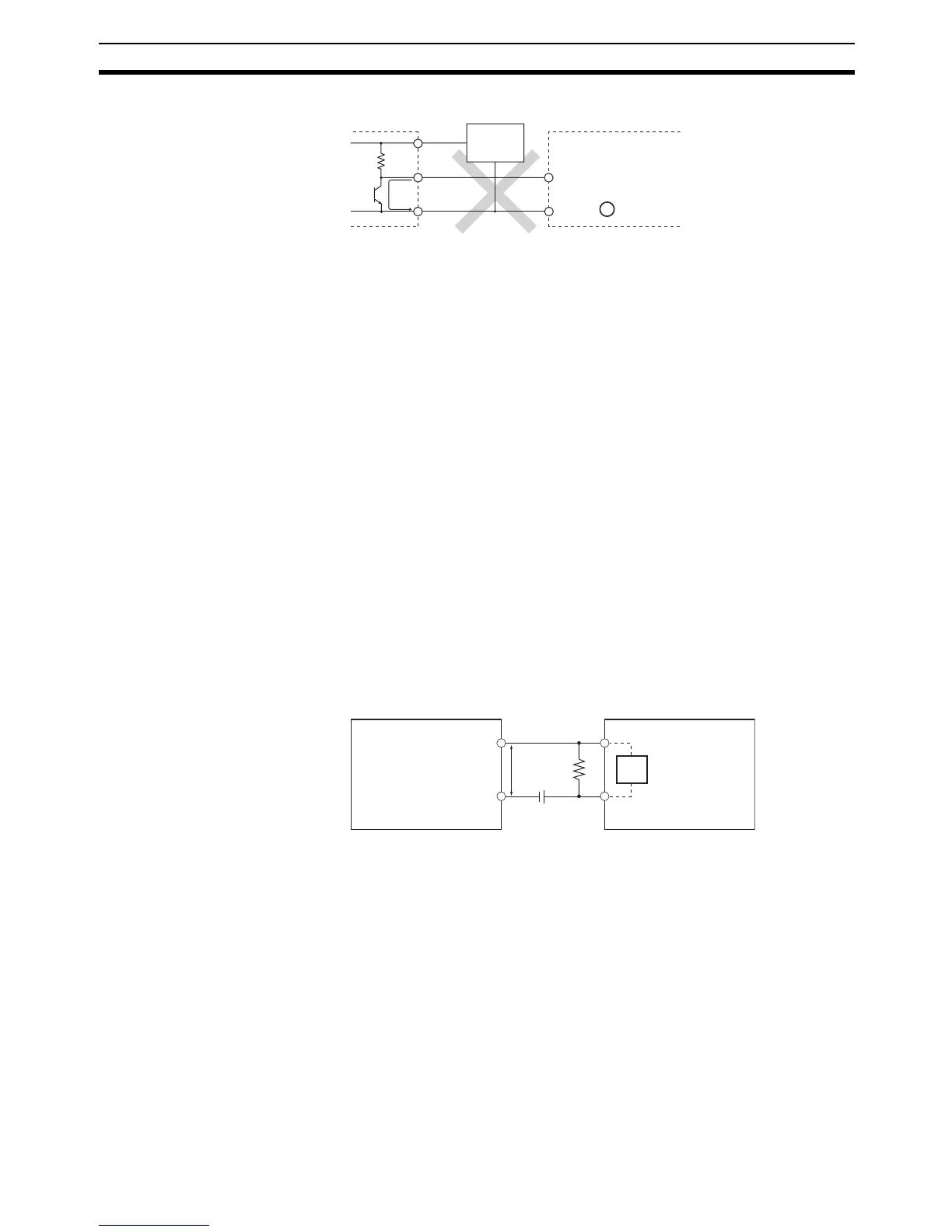

When using a two-wire sensor with a 24-V DC input device, check that the fol-

lowing conditions have been met. Failure to meet these conditions may result

in operating errors.

1,2,3... 1. Relation between voltage when the PLC is ON and the sensor residual

voltage:

V

ON

≤ V

CC

− V

R

2. Relation between current when the PLC is ON and sensor control output

(load current):

I

OUT

(min) ≤ I

ON

≤ I

OUT

(max)

I

ON

= (V

CC

− V

R

− 1.5 [PLC internal residual voltage]*)/R

IN

When I

ON

is smaller than I

OUT

(min), connect a bleeder resistor R. The

bleeder resistor constant can be calculated as follows:

R ≤ (V

CC

− V

R

)/(I

OUT

(min) − I

ON

)

Power W ≥ (V

CC

− V

R

)

2

/R × 4 [allowable margin]

3. Relation between current when the PLC is OFF and sensor leakage cur-

rent:

I

OFF

≥ I

leak

Connect a bleeder resistor if I

leak

is greater than I

OFF

. Use the following

equation to calculate the bleeder resistance constant.

R ≤ R

IN

× V

OFF

/(I

leak

× R

IN

− V

OFF

)

Power W ≥ (V

CC

− V

R

)

2

/R × 4 (allowable margin)

Vcc: Power voltage Vr: Sensor output residual current

Von: PLC ON voltage Iout: Sensor control output (load current)

Voff: PLC OFF voltage

Ion: PLC ON current Ileak: Sensor leakage current

Ioff: PLC OFF current R: Bleeder resistance

Rin: PLC input impedance

4. Precautions on Sensor Inrush Current

An incorrect input may occur due to sensor inrush current if a sensor is

turned ON after the PLC has started up to the point where inputs are pos-

sible. Determine the time required for sensor operation to stabilize after the

sensor is turned ON and take appropriate measures, such as inserting into

the program a timer delay after turning ON the sensor.

IN

CP1H

0 V

+

COM

−

Output

Sensor

power supply

RVR

VCC

RIN

Two-wire Sensor

DC Input Unit

Loading...

Loading...