4-15

4

* The setting is given for 200 V Class Inverters. Double the voltage for 400 V Class Inverters.

• Do not change the Torque Compensation Gain (C4-01) from its default setting of 1.00 when using Open

Loop Vector control.

• If speeds are inaccurate during regeneration in Open Loop Vector control, enable Slip Compensation dur-

ing regeneration (C3-04 = 1).

• Use slip compensation to improve speed control during V/f control (A1-02 = 0).

Set the Motor Rated Current (E2-01), Motor Rated Slip (E2-02), and Motor No-load Current (E2-03), and

then adjust the Slip Compensation Gain (C3-01) between 0.5 and 1.5. The default setting for V/f control is

C3-01 = 0.0 (slip compensation disabled).

• To improve speed response and stability in V/f control with a PG (A1-02 = 1), set the ASR parameters

(C5-01 to C5-05) to between 0.5 and 1.5 times the default value. (Normally it is not necessary to adjust this

setting.)

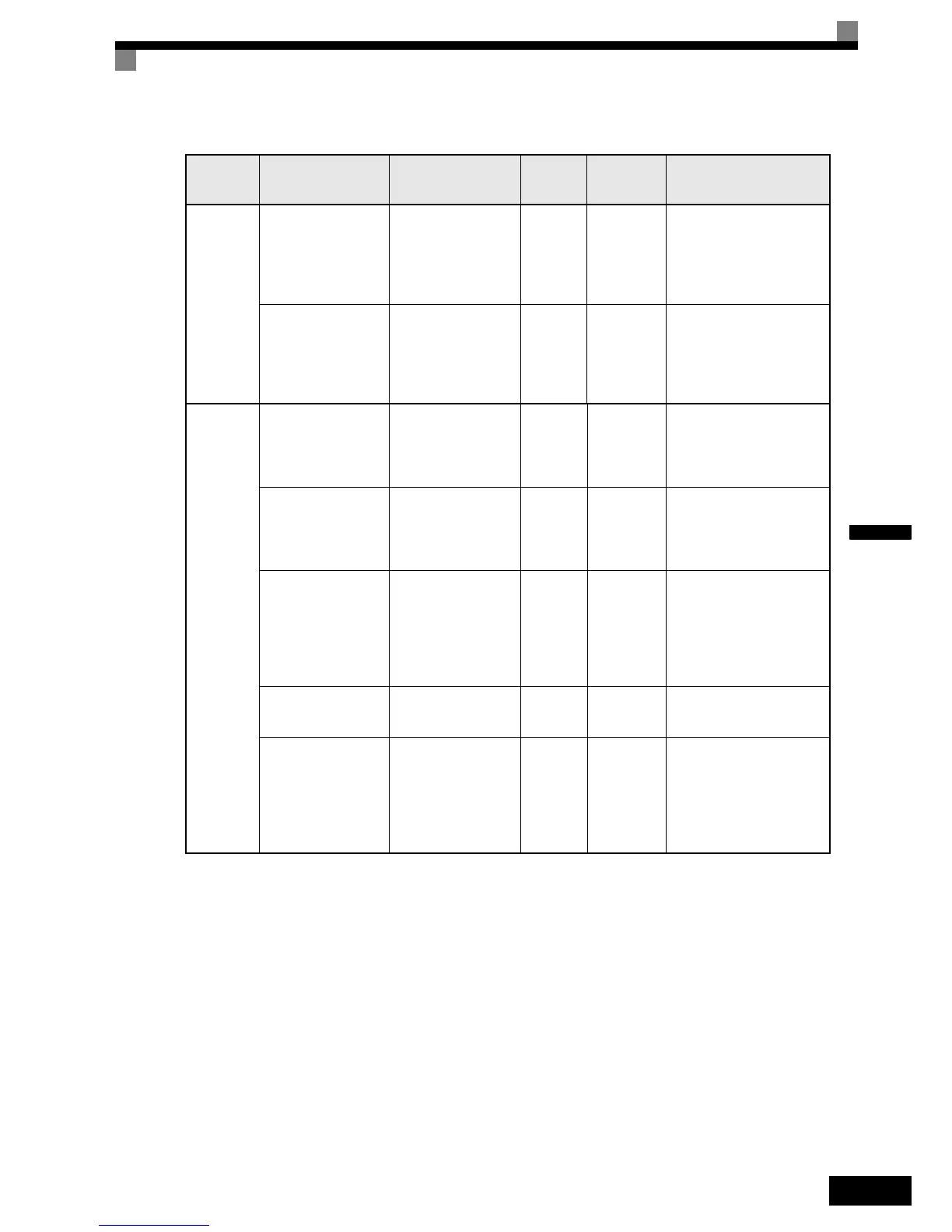

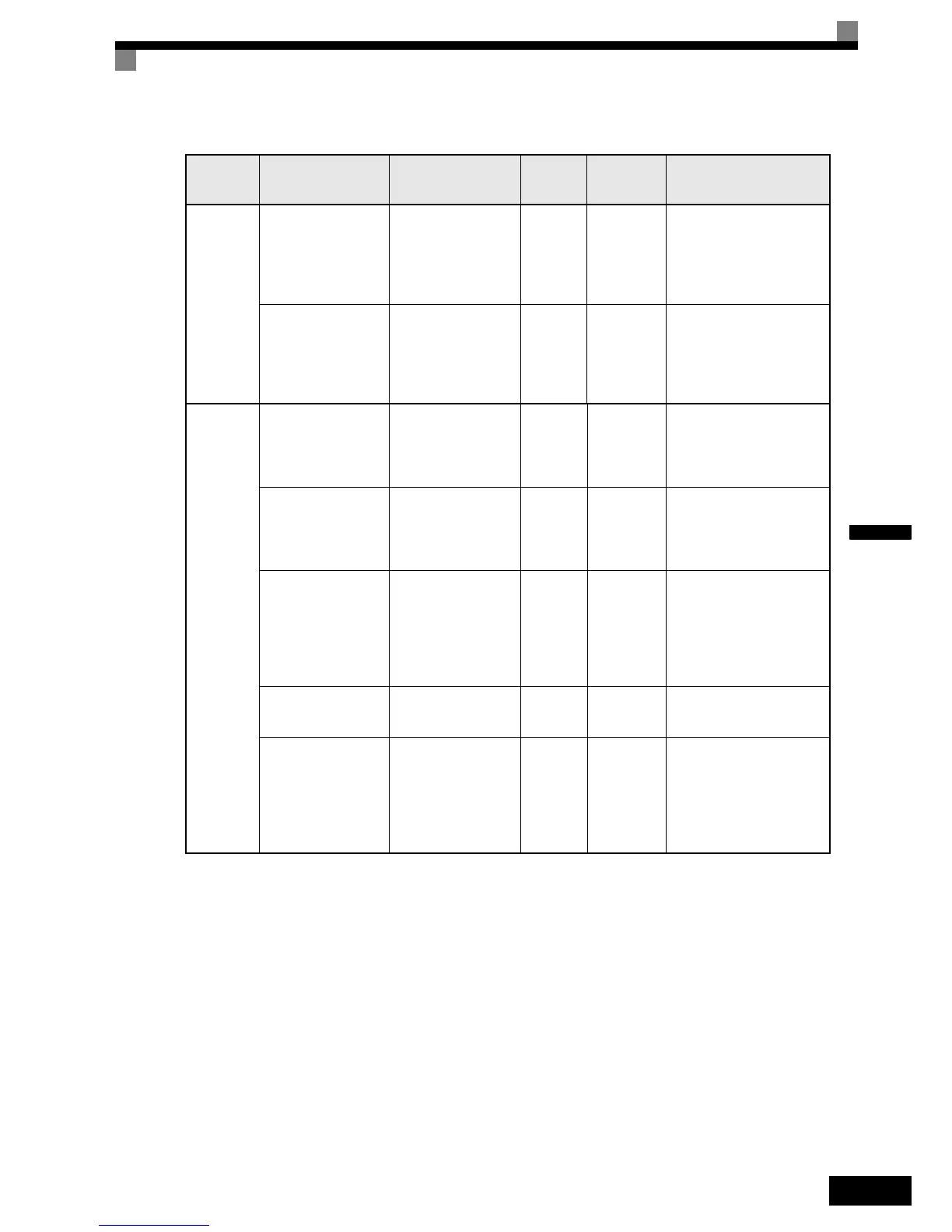

Open Loop

Vector con-

trol (A1-02

= 2)

Carrier frequency

selection (C6-02)

• Reducing motor

magnetic noise

• Controlling hunting

and vibration at low

speeds (10 Hz or

less)

Depends

on capac-

ity

0 to

default

• Increase the setting if

motor magnetic noise is

high.

• Reduce the setting if hunt-

ing or vibration occurs at

low speeds.

Middle output fre-

quency voltage

(E1-08)

Minimum output fre-

quency voltage

(E1-10)

• Improving torque at

low speeds

• Controlling shock at

startup

Depends

on capac-

ity and

voltage

Default to

Default +

5V

*

• Increase the setting if

torque or speed response is

low.

• Reduce the setting if shock

at startup is large.

Closed

Loop Vec-

tor control

(A1-02 = 3)

ASR proportional gain

1 (C5-01) and

ASR proportional gain

2 (C5-03)

• Torque and speed

response

• Controlling hunting

and vibration

20.00

10.00 to

50.00

• Increase the setting if

torque or speed response is

low.

• Reduce the setting if hunt-

ing or vibration occurs.

ASR integral time 1

(high-speed) (C5-02)

and

ASR integral time 2

(low-speed) (C5-04)

• Torque and speed

response

• Controlling hunting

and vibration

0.500 s

0.300 to

1.000 s

• Reduce the setting if

torque or speed response is

low.

• Increase the setting if hunt-

ing or vibration occurs.

ASR switching fre-

quency (C5-07)

Switching the ASR

proportional gain and

integral time accord-

ing to the output fre-

quency

0.0 Hz

0.0 to max.

output fre-

quency

Sets the output frequency at

which to change the ASR

proportional gain and inte-

gral time when the same val-

ues cannot be used for high-

speed and low-speed opera-

tion.

ASR primary delay

time (C5-06)

• Controlling hunting

and vibration

0.004 s

0.004 to

0.020

Increase the setting if

machine rigidity is low and

the system vibrates easily.

Carrier frequency

selection (C6-02)

• Reducing motor

magnetic noise

• Controlling hunting

and vibration at low

speeds (3 Hz or less)

Depends

on the

capacity.

2.0 kHz to

default

• Increase the setting if

motor magnetic noise is

too high.

• Reduce the setting if hunt-

ing or vibration occurs at

very low to middle-range

speeds.

Table 4.4 Adjusted Parameters (Continued)

Control

Method

Name (Parameter

Number)

Influence

Factory

Setting

Recom-

mended

Setting

Adjustment Method

Loading...

Loading...