4-16

4

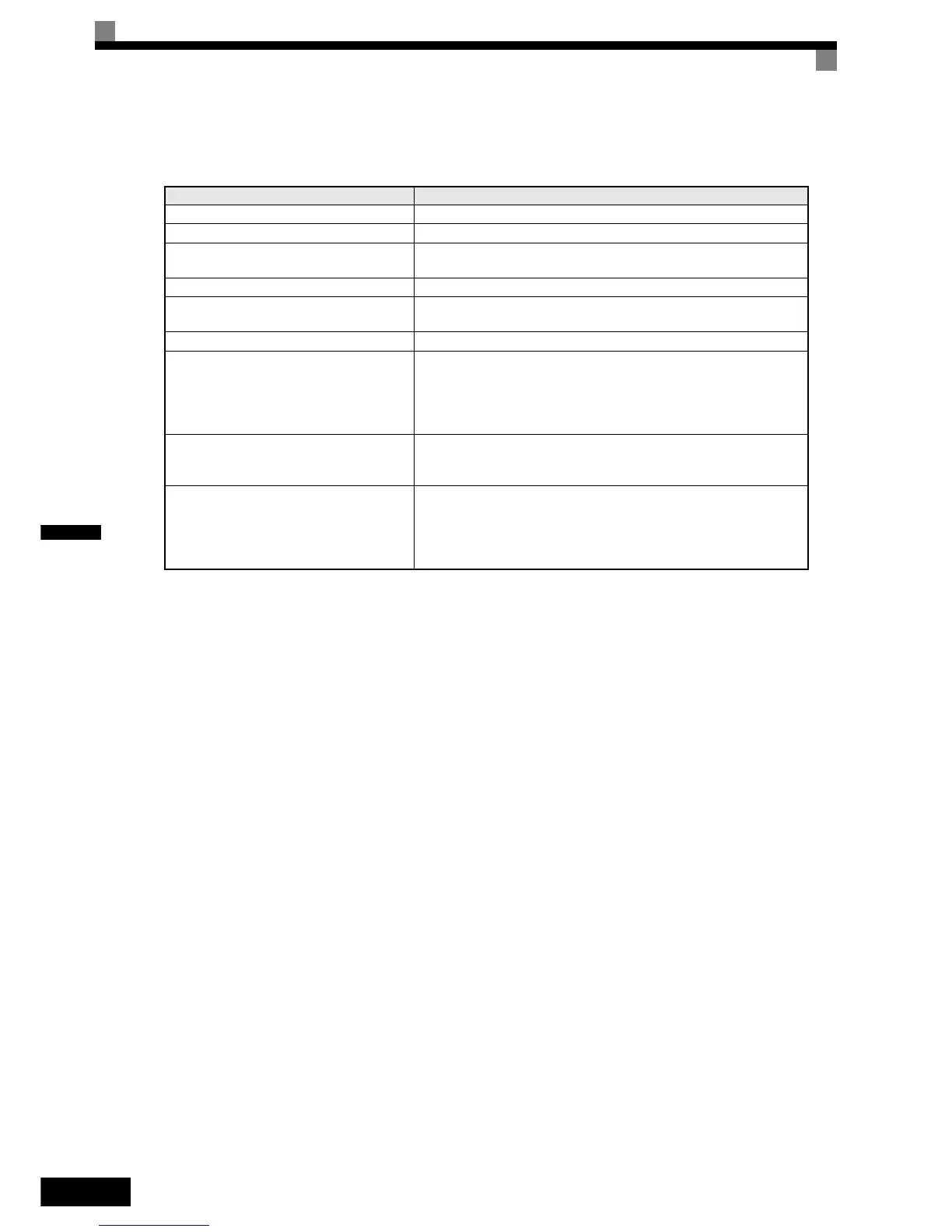

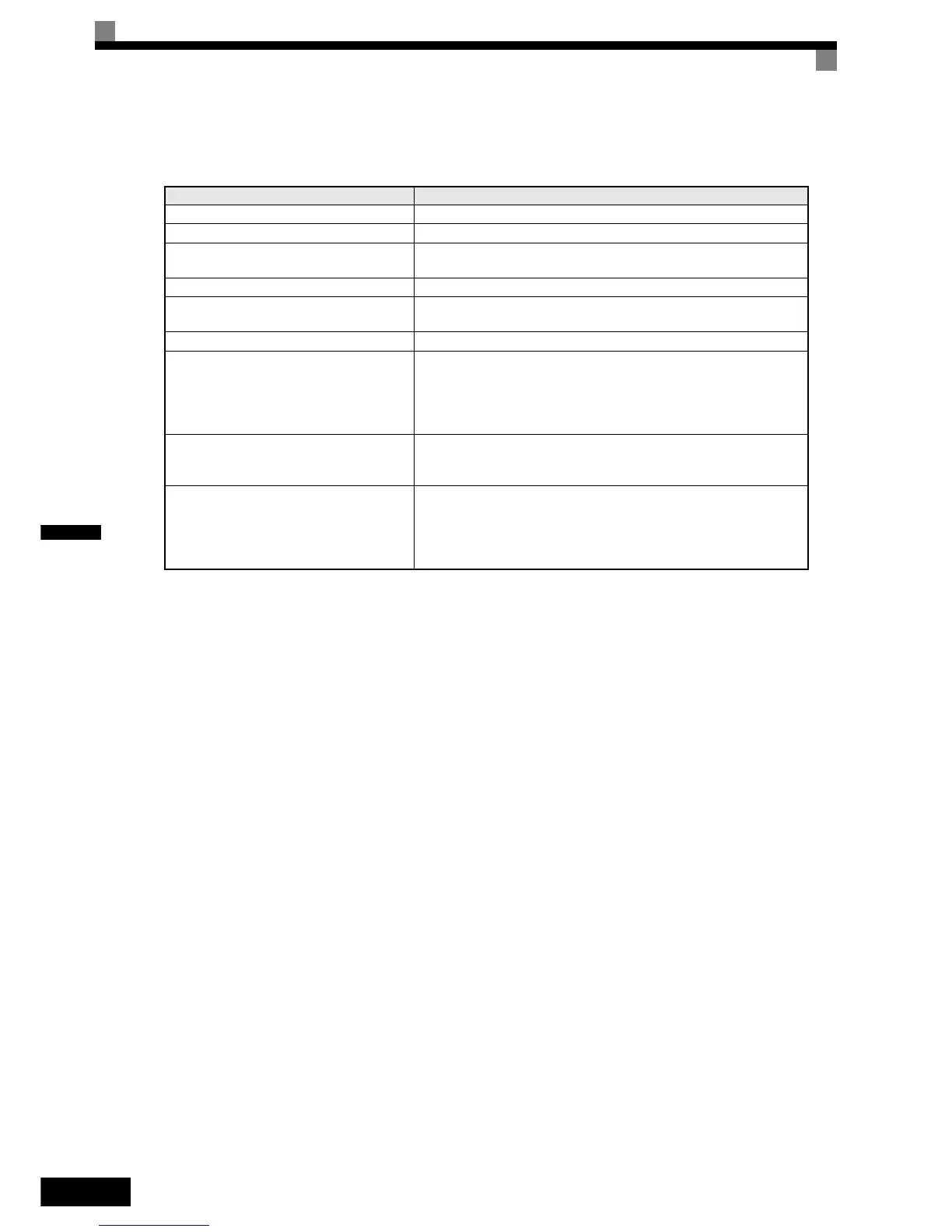

The following parameters will also affect the control system indirectly.

Table 4.5 Parameters Which Affect Control and Applications Indirectly

Name (Parameter Number) Application

Heavy/Normal Duty selection (C6-01) Sets the maximum torque and overload capability.

DWELL function (b6-01 to b6-04) Used for heavy loads or large machine backlashes.

Acceleration/deceleration times

(C1-01 to C1-11)

By adjusting the acceleration and deceleration times the torque is influ-

enced indirectly.

S-curve characteristics (C2-01 to C2-04) Used to prevent shock at the acceleration/deceleration start and end.

Jump frequencies (d3-01 to d3-04)

Used to avoid continuous operation at possible machine resonance fre-

quencies.

Analog input filter time constant (H3-12) Used to prevent fluctuations in analog input signals caused by noise.

Stall prevention (L3-01 to L3-06)

Used to prevent OV (overvoltage faults) and motor stalling for heavy

loads or rapid acceleration/deceleration. Stall prevention is enabled by

default and the setting normally has not to be changed. When using a

braking resistor disable the stall prevention during deceleration by setting

L3-04 to 0 or set it to 3 (enabled with braking resistor).

Torque limits (L7-01 to L7-04)

Sets the maximum torque during Open Loop and Closed Loop Vector

control. If a setting is reduced too much, stalling can occur under heavy

loads.

Feed forward control (n5-01 to n5-03)

Used to increase response for acceleration/deceleration or to reduce over-

shooting when there is low machine rigidity and the gain of the speed

controller (ASR) cannot be increased. The inertia ratio between the load

and motor and the acceleration time of the motor running unloaded must

be set.

Loading...

Loading...