4-2

4

Trial Operation Procedure

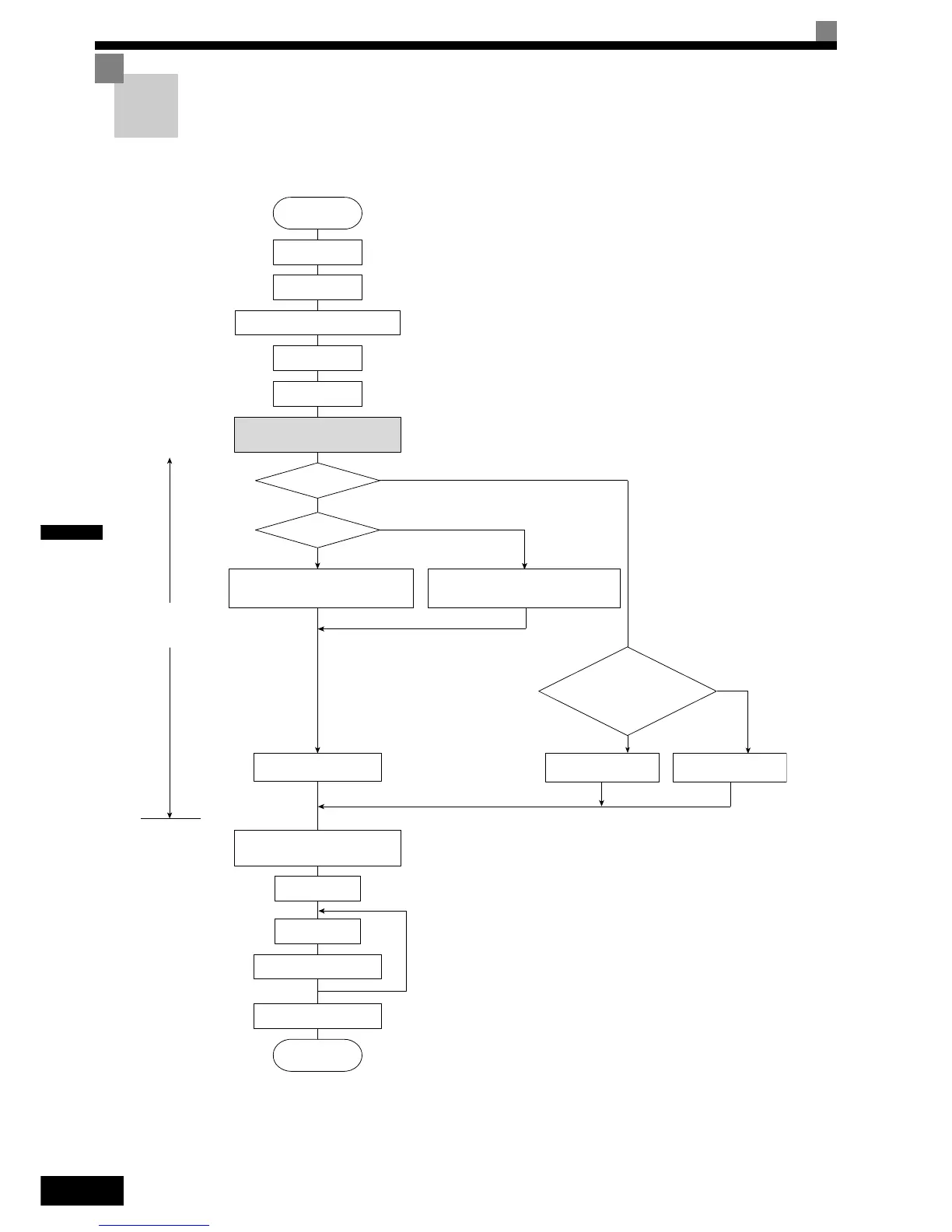

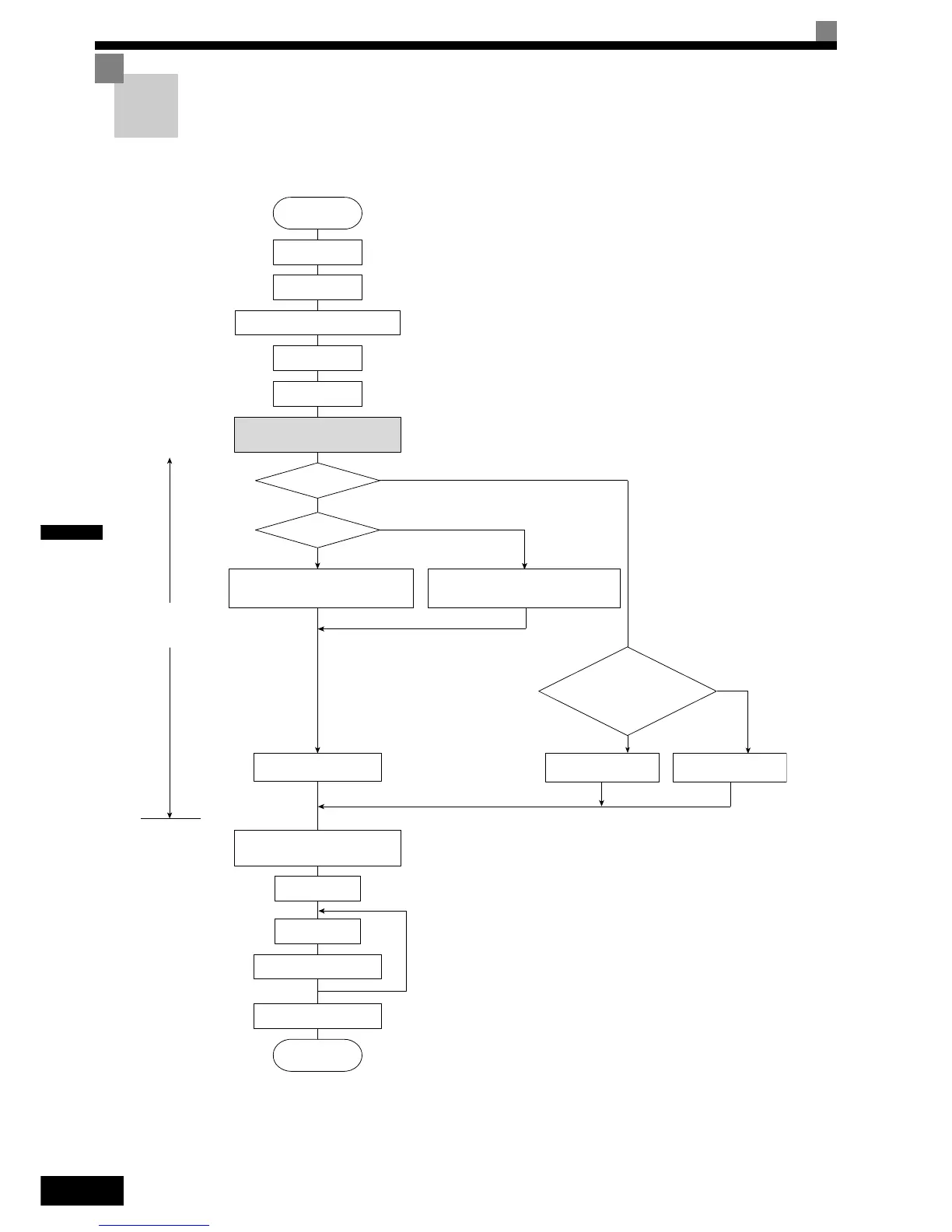

Perform trial operation according to the following flowchart. When setting the basic parameters, always set

C6-01 (Heavy/Normal Duty Selection) according to the application.

Fig 4.1 Trial Operation Flowchart

V/f Control with PG (A1-02=1)

START

Installation

Wiring

Turn ON power.

Confirm status.

Basic settings

(Quick programming mode)

Set power supply voltage jumper.

Select operating

method.

Settings according

to control mode

Application settings

(Advanced programming mode)

No-load operation

Loaded operation

Optimum adjustments and

parameter settings

Check/record parameters.

END

YES

V/f control

Vector Control (A1-02=2 or 3)*5

Set E1-03.

V/f default: 200V/50Hz(400V/50Hz)

Set E1-03, E2-04, and F1-01.

V/f default: 200V/50Hz (400V/50Hz)

YES

NO

V/f control?

PG?

Motor operation during

autotuning possible?

Non-rotating autotuning

for line-to-line resistance

Rotating

autotuning

Non-rotating

autotuning

*3

*4

*2

*1

*6

*6

NO

NO

YES

1. Set for 400 V Class Inverter for 75 kW or more.

2. If there is a reduction gear between the motor and PG, set the

reduction ratio in F1-12 and F1-13 in advanced programming

mode.

3. Use rotational autotuning to increase autotuning accuracy when-

ever it is okay for the motor to be operated.

4. If the motor cable changes to 50 m or longer for the actual instal-

lation, perform non-rotating autotuning for the line-to-line resis-

tance only on site.

5. The default control mode is Open Loop Vector control

(A1-02=2).

6. If the maximum output frequency and the base frequency are dif-

ferent, set the maximum output frequency (E1-04) after autotun-

ing.

Loading...

Loading...