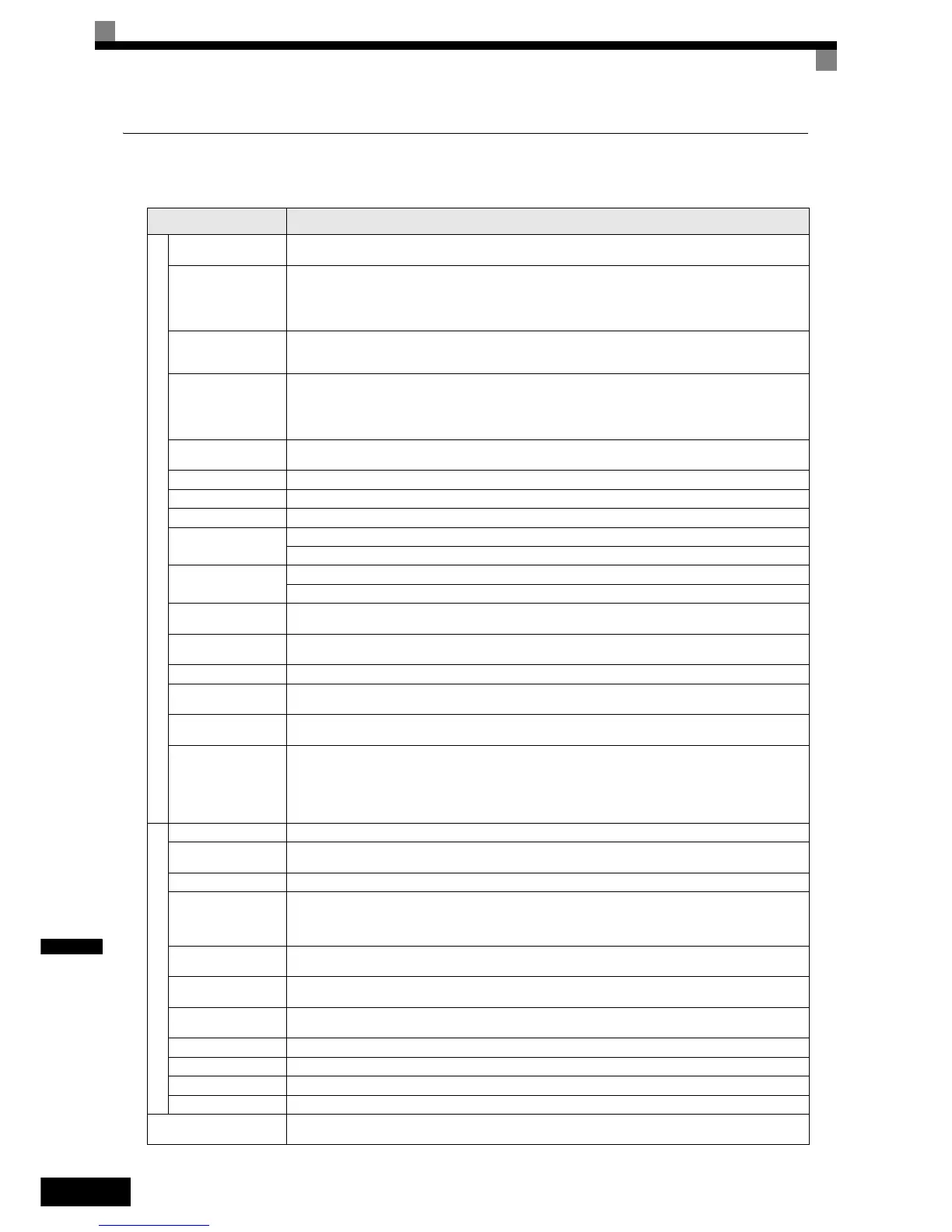

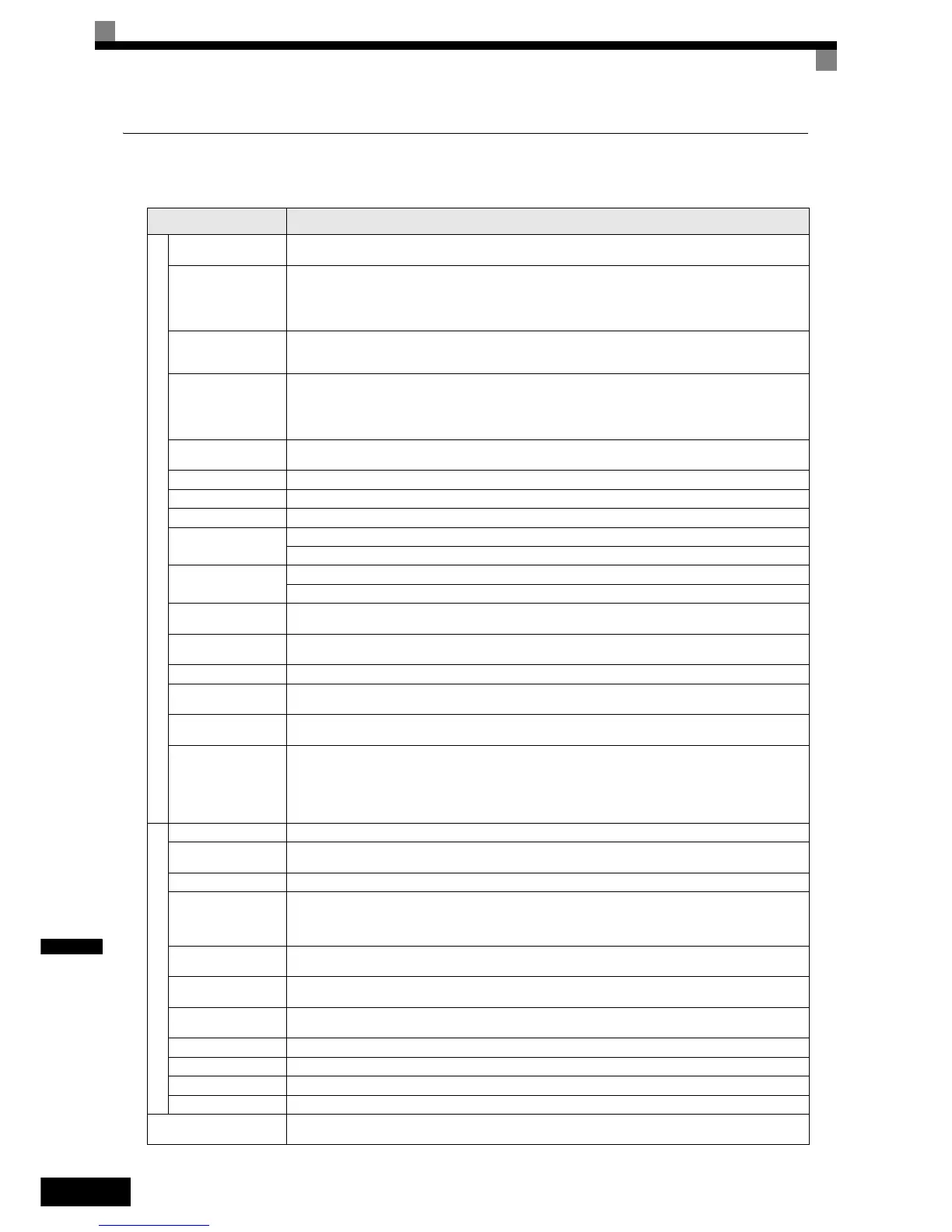

9-4

9

Common Specifications

The following specifications apply to both 200 V and 400 V class Inverters.

Model Number

CIMR-F7Z

Specification

Control method

Sine wave PWM

Closed Loop Vector control, Open Loop Vector control, V/f control, V/f with PG control

Torque characteristics

Heavy Duty (low carrier, constant torque applications): 2 kHz carrier frequency, 150% overload for 1 minute,

higher carrier frequency possible with current derating.

Normal Duty 1 (high carrier, variable torque applications): maximum carrier frequency, depending on inverter capacity,

120% overload for 1 minute.

Normal Duty 2 (variable torque applications): carrier frequency reduced, continuous overload capability increased

Speed control range

1:40 (V/f control)

1:100 (Open Loop Vector control)

1:1000 (Closed Loop Vector control)

Speed control accuracy

± 3% (V/f control)

± 0.03% (V/f control with PG)

± 0.2% (Open Loop Vector control)

± 0.02% (Closed Loop Vector control)

(25°C ± 10°C)

Speed control response

5 Hz (control without PG)

30 Hz (control with PG)

Torque limits Provided (4 quadrant steps can be changed by parameter settings.) (Vector control)

Torque accuracy ± 5%

Frequency range 0.01 to 150 Hz (Heavy Duty), 0.01 to 400 Hz (Normal Duty 1 or 2)

Frequency accuracy (tem-

perature characteristics)

Digital references: ± 0.01% (-10°C to +40°C)

Analog references: ± 0.1% (25°C ±10°C)

Frequency setting resolu-

tion

Digital references: 0.01 Hz

Analog references: 0.025/50 Hz (11 bits plus sign)

Output frequency resolu-

tion

0.01 Hz

Overload capacity and

maximum current

Heavy Duty (low carrier, constant torque applications): 150% of rated output current for 1 minute

Normal Duty 1 or 2 (high/reduced carrier, variable torque applications): 120% of rated output current for 1 minute

Frequency setting signal 0 to +10V, –10 to +10 V, 4 to 20 mA, pulse train

Acceleration/Decelera-

tion time

0.01 to 6000.0 s (4 selectable combinations of independent acceleration and deceleration time settings)

Braking torque

Approximately 20% (Approximately 125% with Braking Resistor option,

braking transistor built into Inverters of 18.5 kW or less)

Main control functions

Restarting after momentary power loss, speed search, overtorque/undertorque detection, torque limits, 17-speed control (max-

imum), 4 acceleration and deceleration times, S-curve acceleration/deceleration, 3-wire control, auto-tuning (rotational or sta-

tionary), dwell function, cooling fan ON/OFF control, slip compensation, torque compensation, auto-restart after fault, jump

frequencies, upper and lower limits for frequency references, DC braking for starting and stopping, high-slip braking,

advanced PID control, energy-saving control, MEMOBUS communications (RS-485/422, 19.2 kbps maximum), 2 motor

parameter sets, fault reset and parameter copy function.

Motor protection Protection by electronic thermal overload relay.

Instantaneous overcurrent

protection

Stops at approx. 200% of rated output current.

Fuse blown protection Stops for fuse blown.

Overload protection

Heavy Duty (low carrier, constant torque applications): 150% of rated output current for 1 minute

Normal Duty 1 (high carrier, variable torque applications): 120% of rated output current for 1 minute

Normal Duty 2 (high carrier, variable torque applications): 120% of rated output current for 1 minute,

increased continuous output current.

Overvoltage protection

200 Class Inverter: Stops when main-circuit DC voltage is above 410 V.

400 Class Inverter: Stops when main-circuit DC voltage is above 820 V.

Undervoltage protection

200 Class Inverter: Stops when main-circuit DC voltage is below 190 V.

400 Class Inverter: Stops when main-circuit DC voltage is below 380 V.

Momentary power loss

ride through

By selecting the momentary power loss method, operation can be continued if power is restored within 2 s.

Cooling fin overheating Protection by thermistor.

Stall prevention Stall prevention during acceleration, deceleration and running independently.

Grounding protection Protection by electronic circuits.

Charge indicator Glows when the main circuit DC voltage is approx. 10 VDC or more.

Protective structure

Enclosed wall-mounted type (NEMA 1): 18.5 kW or less (same for 200 V and 400 V class Inverters)

Open chassis type (IP00): 22 kW or more (same for 200 V and 400 V class Inverters)

Loading...

Loading...