6-39

6

Adjusting the Torque Compensation Primary Delay Time Constant (C4-02)

The setting value of C4-02 depends on the control method. The factory settings are:

• V/f control without PG: 200 ms

• V/f control with PG: 200 ms

• Open loop vector control: 20 ms

Normally, there is no need to change this setting. If adjustments are necessary do the following:

• If the motor is vibrating, increase the set value.

• If the torque response is slow, decrease the set value.

Starting Torque Compensation Function (C4-03 to C4-05)

A starting torque compensation can be applied to speed up the torque establishment at start in Open Loop Vec-

tor control.

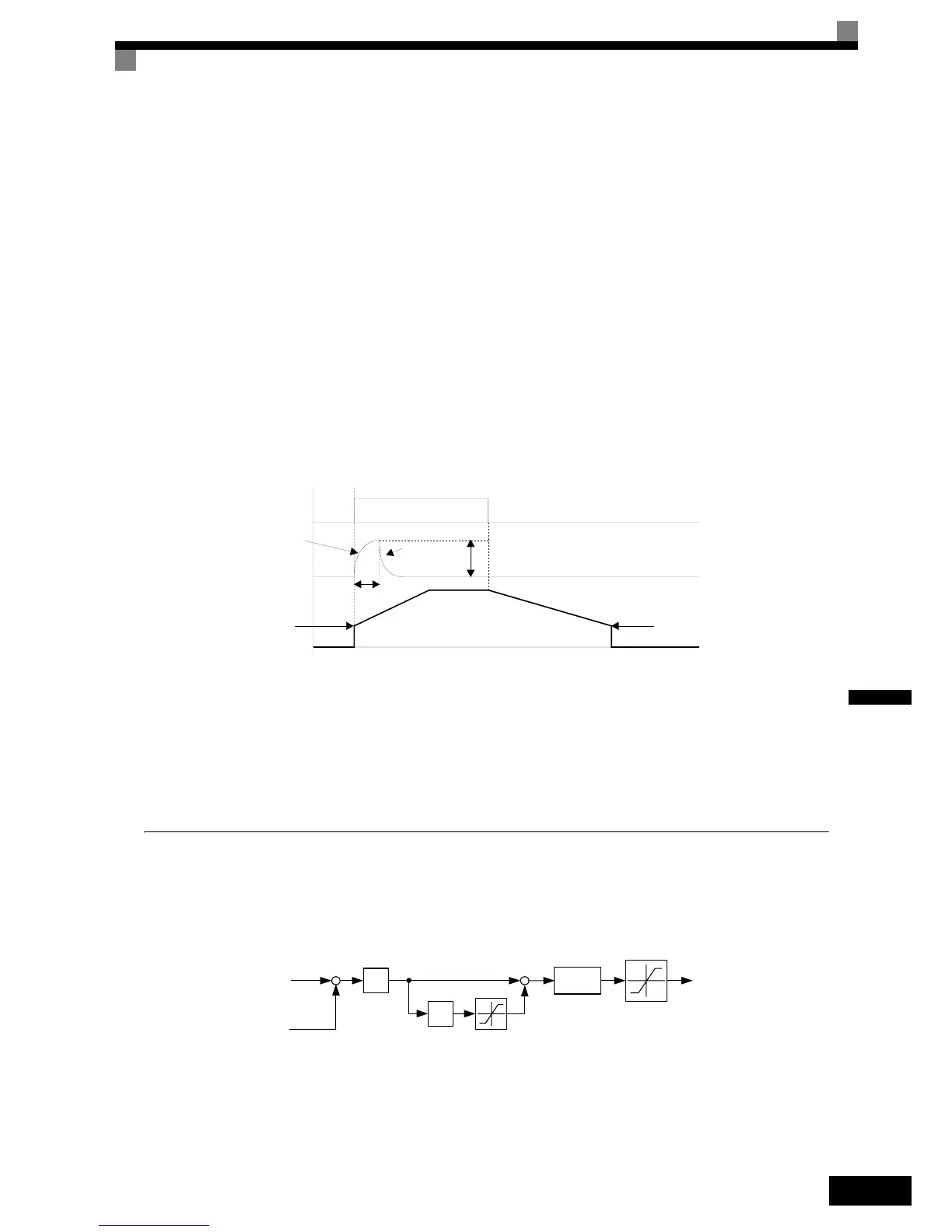

This function is effective for machinery with large friction loads and applications, where high starting torque

is required. It works like shown in the following diagram.

Fig 6.40 Time Chart for Starting Torque Frequency

When this function is used, the following should be considered:

• When the machine runs in FWD and REV direction both values, C4-03 and C4-04 have to be set.

• The compensation works for motoring operation only. It can not be used for regenerative operation.

• If the starting torque compensation is used and a large shock is generated at the start, increase the starting

torque compensation time constant (C4-05).

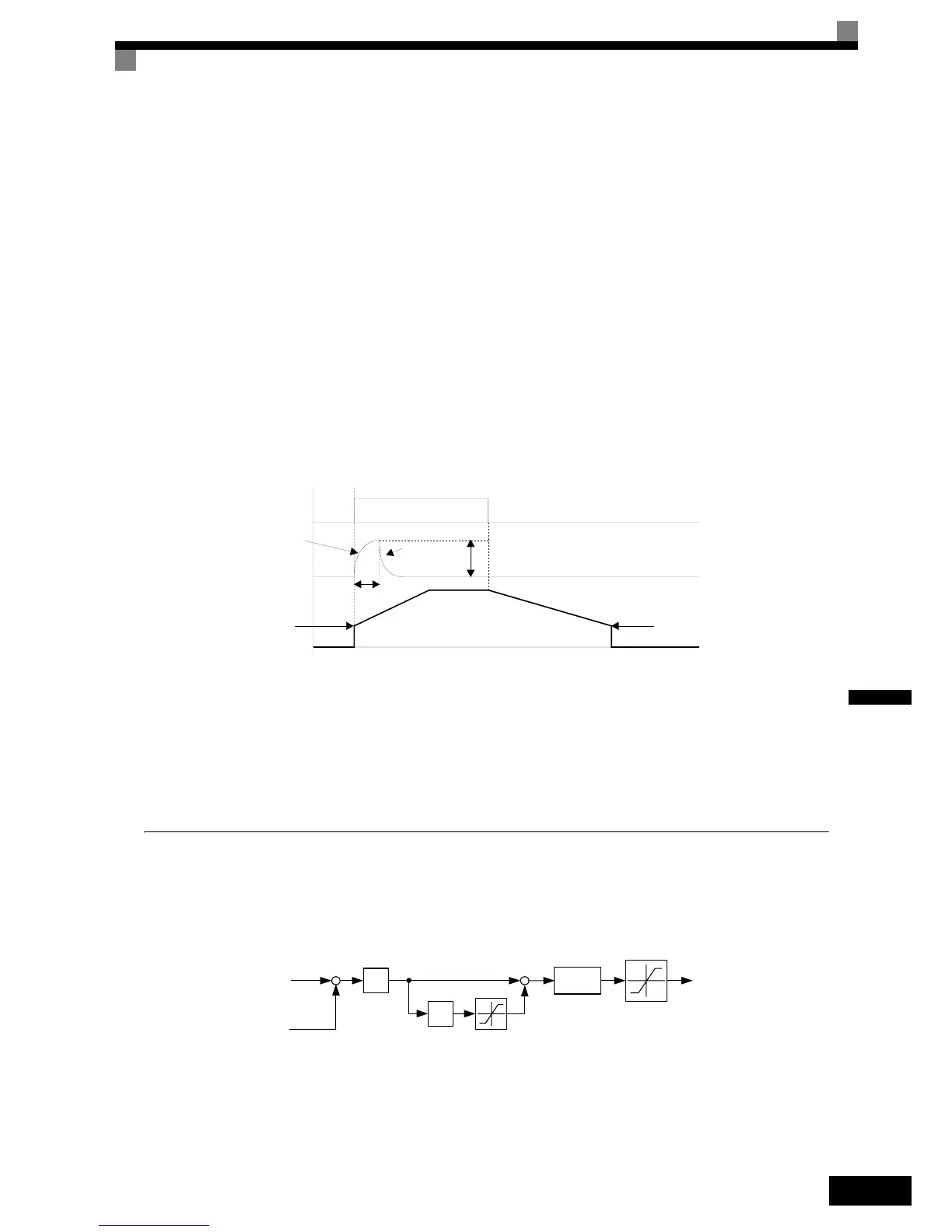

Automatic Speed Regulator (ASR)

In Closed Loop Vector control the automatic speed regulator (ASR) adjusts the torque reference in order to

eliminate the deviation between the speed reference and the measured speed (PG feedback). Fig 6.41 shows

the ASR structure for Closed Loop Vector control.

Fig 6.41 ASR Structure for Closed Loop Vector Control

OFF

ON

Forward (Reverse) Run command

Time constant: C4-05

Time constant: C4-02

C4-05 x 4

Torque compensation

volume

E1-09

Output frequency

The larger value of b2-01

and E1-09

C4-03 (forward)

C4-04 (reverse, negative polarity)

Frequency

Reference

Motor

Speed

Torque

Reference

P

I

+

-

+

+

C5-01/03

C5-02/04

Torque

Limits

Delay

Timer

C5-06

C5-08

I-Limit

Loading...

Loading...