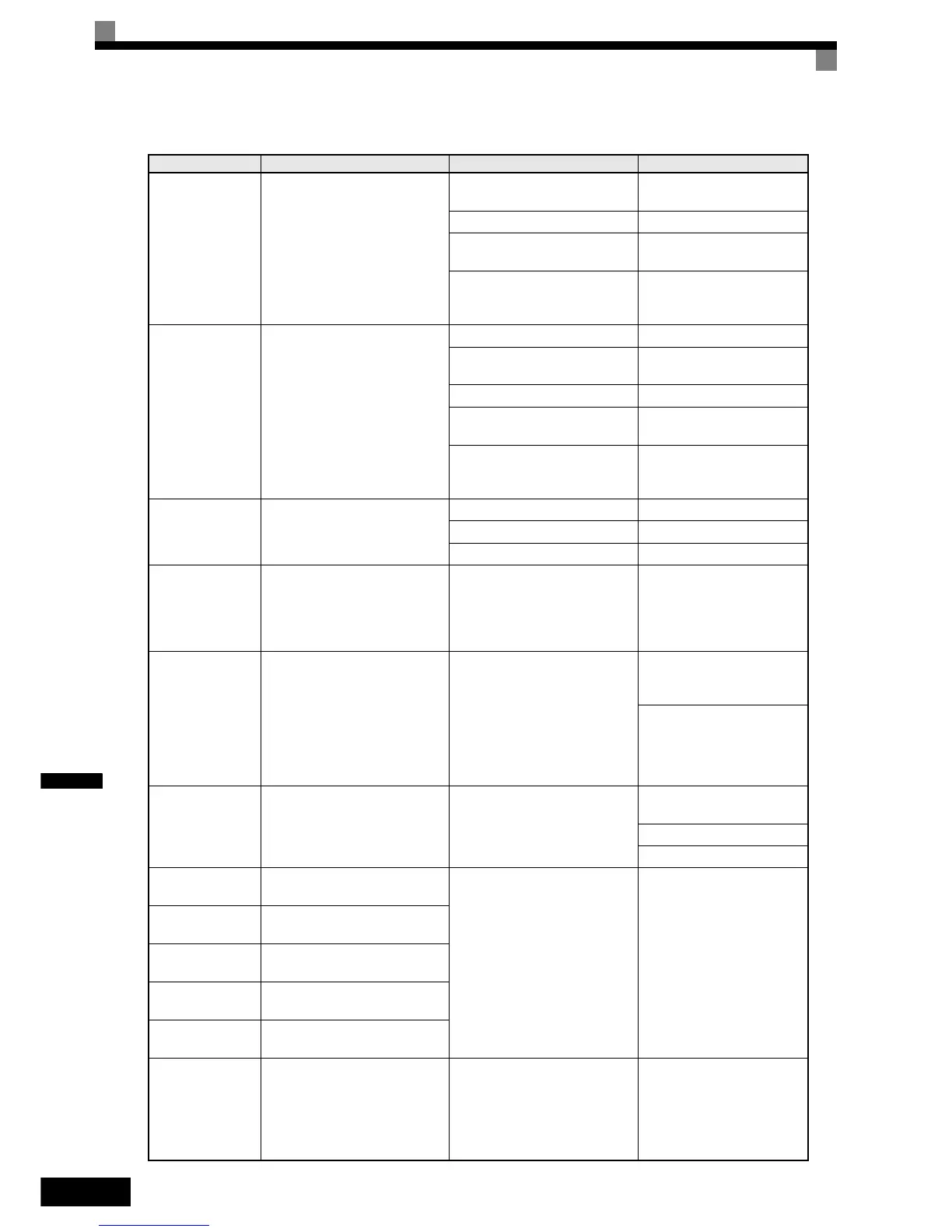

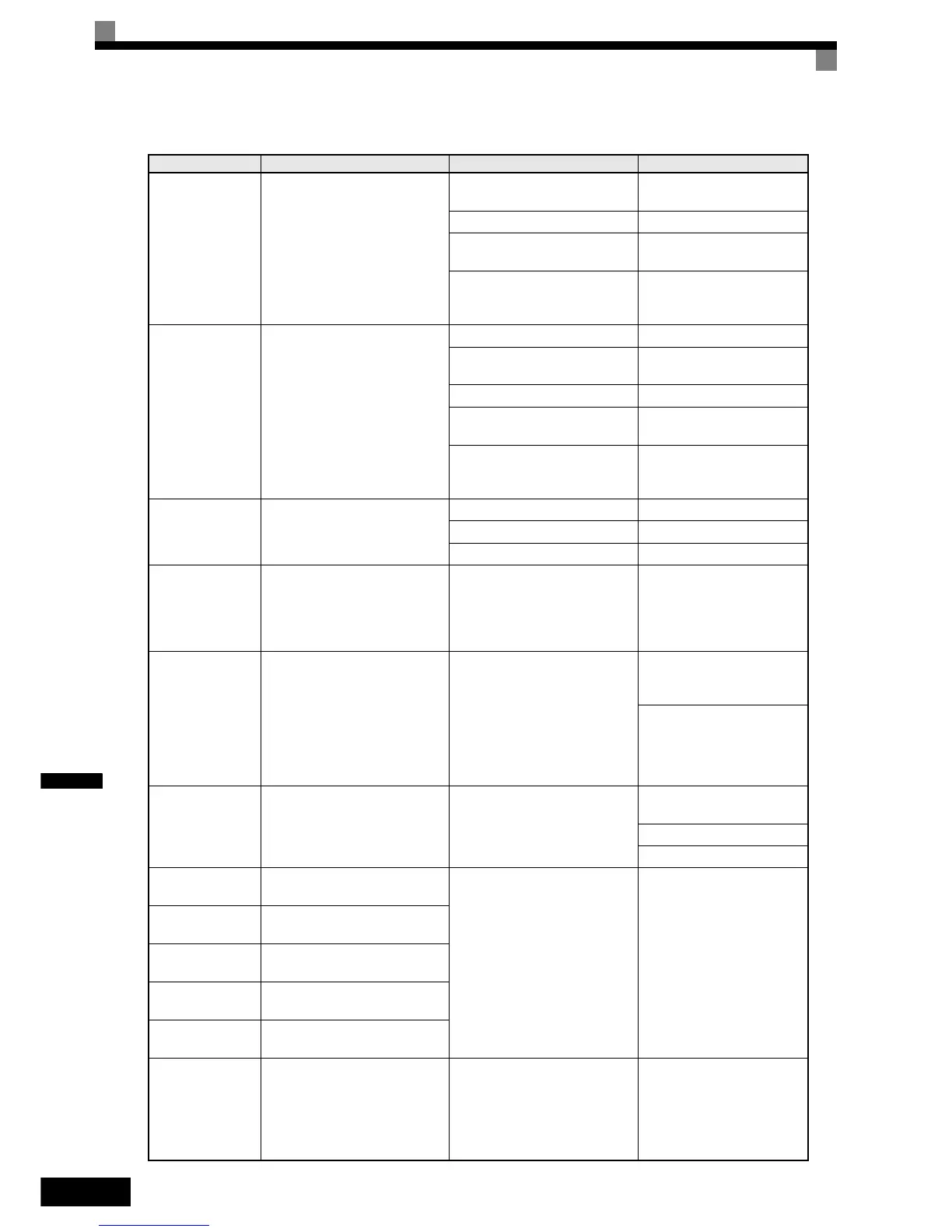

7-6

7

PGO

PG Open

PG Disconnection

Detected when F1-02 = 0 to 2 and

A1-02 = 1 or 3

Detected when no PG (encoder)

pulses are received for a time

longer than the setting in F1-14.

There is a break in the PG wiring.

Fix the broken/disconnected

wiring.

The PG is wired incorrectly. Fix the wiring.

Power is not being supplied to

the PG.

Supply power to the PG

properly.

Wrong brake control sequence

when a brake is used.

Check if the brake is opened

when the RUN command is

applied.

DEV

Speed Deviation

Excessive Speed Deviation

Detected when F1-04 = 0 to 2 and

A1-02 = 1 or 3

The speed deviation is greater

than the setting in F1-10 for a

time longer than the setting F1-11

The load is too large. Reduce the load.

The acceleration time and decel-

eration time are too short.

Lengthen the acceleration

time and deceleration time.

The load is locked. Check the mechanical system.

The settings in F1-10 and F1-11

are not appropriate.

Check the settings in F1-10

and F1-11.

Wrong brake control sequence

when a brake is used.

Check if the brake is opened

when the RUN command is

applied.

SVE

Zero Servo Fault

Zero Servo Fault

The motor position moved during

Zero Servo Operation.

The torque limit is too small. Increase the torque limit.

The load torque is too large. Decrease the load torque.

- Check for signal noise.

CF

Out of Control

Control Fault

A torque limit was reached con-

tinuously for 3 seconds or longer

during a deceleration stop in Open

Loop Vector control.

Motor parameters were not set

properly.

Check the motor parameters.

FBL

Feedback Loss

PID Feedback Lost

This fault occurs when PID feed-

back loss detection is pro-

grammed to fault (b5-12 = 2) and

the PID feedback fell below the

PID Feedback Loss Detection

Level (b5-13) for the PID Feed-

back Loss Detection Time (b5-14)

PID feedback source (e.g. trans-

ducer, sensor, building automa-

tion signal) is not installed

correctly or is not working.

Verify Inverter is pro-

grammed to receive the PID

feedback source signal.

Check to ensure the PID feed-

back source is installed and

working properly.

EF0

Opt External Flt

External fault input from Commu-

nications Option Card

An external fault condition was

present, input from a communica-

tion option card.

Check for an external fault

condition.

Verify the parameters.

Verify communication signals

EF3

Ext Fault S3

External fault at terminal S3

An "external fault" was input

from a multi-function input termi-

nal (S3 to S7).

Eliminate the cause of the

external fault condition.

EF4

Ext Fault S4

External fault at terminal S4

EF5

Ext Fault S5

External fault at terminal S5

EF6

Ext Fault S6

External fault at terminal S6

EF 7

Ext Fault S7

External fault at terminal S7

OPR

Oper Disconnect

Digital Operator Connection Fault

Detected when the digital opera-

tor is removed and the Inverter

receives its RUN command

through the digital operator

(b1-02=0)

The digital operator was removed

during running or the operator

cable is broken.

Check the connection of the

Digital Operator.

Table 7.1 Fault Detection

Display Meaning Probable Causes Corrective Actions

Loading...

Loading...