4-9

4

motor nameplate and additiona the motor no-load current from the motor manufacturer’s motor test result and

press the RUN key on the Digital Operator.

If T1-09 is not set the value of a Yaskawa standard motor will be used.

Precautions Before Using Autotuning

Read the following precautions before using autotuning.

• Autotuning an Inverter is fundamentally different from autotuning a servo system. Inverter autotuning

automatically adjusts parameters according to detected motor data, whereas servo system autotuning

adjusts parameters according to the detected size of the load.

• When speed precision or torque precision is required at high speeds (i.e., 90% of the rated speed or higher),

use a motor with a rated voltage that is ~20 V less than the input power supply voltage of the Inverter for

200 V-class Inverters and ~40 V less for 400 V-class Inverters. If the rated voltage of the motor is the same

as the input power supply voltage, the voltage output from the Inverter will be unstable at high speeds and

sufficient performance will not be possible.

• Use non-rotating autotuning 1 or 2 whenever the load cannot be disconnected from the motor.

• Use rotating autotuning whenever performing autotuning when high precision is required or for a motor

that is not connected to a load.

• If rotating autotuning is performed for a motor connected to a load, the motor data will not be found accu-

rately and the performance might be poor. Never perform rotating autotuning for a motor connected to a

load.

• If the wiring between the Inverter and motor changes by 50 m or more perform non-rotating autotuning for

line-to-line resistance.

• If the motor cable is long (50 m or longer), perform non-rotating autotuning for line-to-line resistance.

• If a mechanical brake is used, make sure that it is not opened for non-rotating autotuning. Make sure that it

is opened for rotating autotuning.

• Power will be supplied to the motor when a non-rotating autotuning is performed even though the motor

will not turn. Do not touch the motor until autotuning has been completed

.

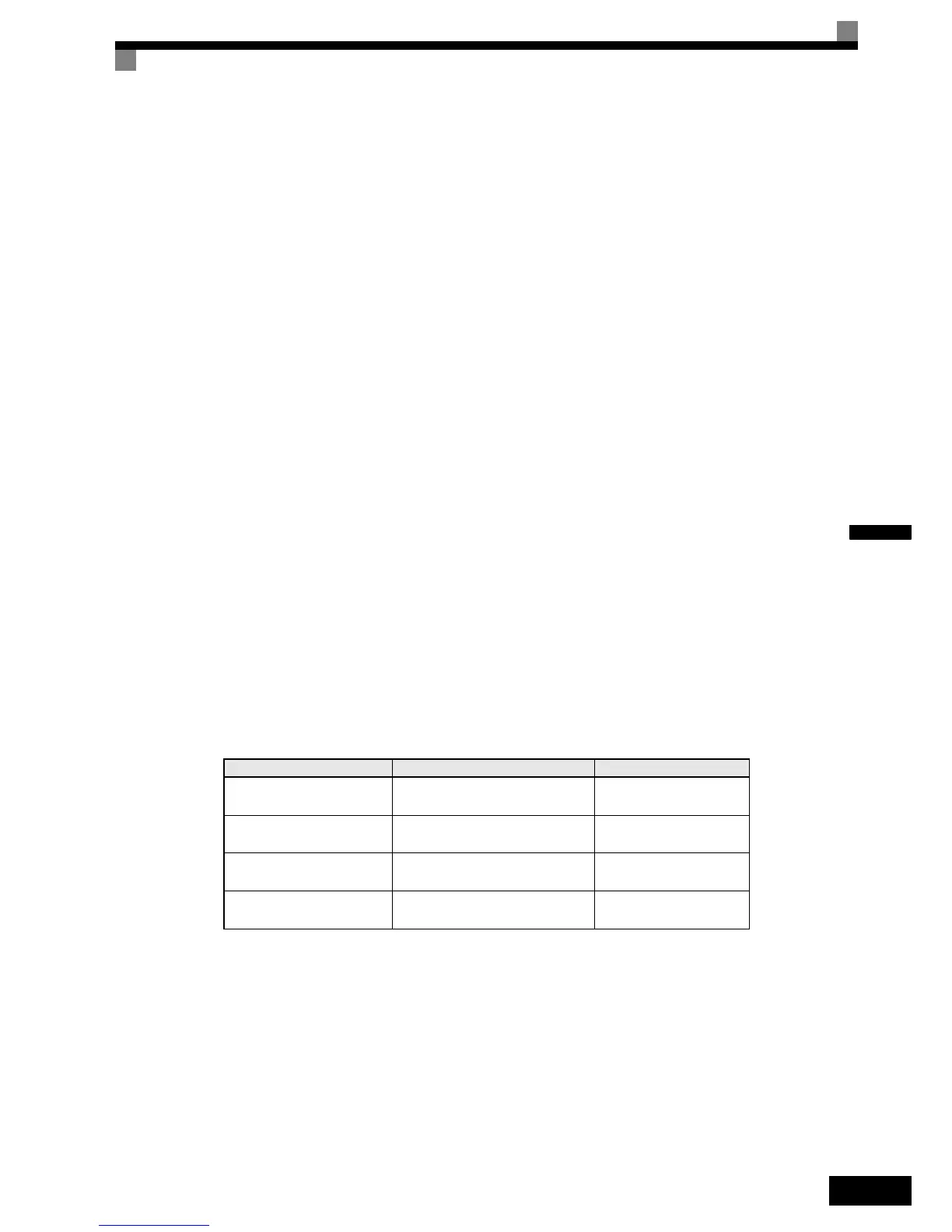

• The status of the multi-function inputs and multi-function outputs during autotuning will be as shown in

the following table.

• To cancel autotuning, press the STOP key on the Digital Operator.

Tuning Mode Multi-function Inputs Multi-function Outputs

Rotating autotuning Do not work

Same as during normal

operation

Non-rotating autotuning 1 Do not work

Maintain same status as

when autotuning is started.

Non-rotating autotuning for

line-to-line resistance

Do not work

Maintain same status as

when autotuning is started.

Non-rotating autotuning 2 Do not work

Maintain same status as

when autotuning started.

Loading...

Loading...