~

en

z

«

:r:

()

w

~

3-4. MAINTENANCE PROCEDURES

3-4-1. REGULAR MAINTENANCE

The purpose

of

periodic maintenance

is

to

preserve

the functioning

of

this

machine

throughout

its

useful life. The user

or

service dealer should

perform

these maintenance

regularly

to

ensure

that

maximum

utility

is

obtained

from

the machine.

The VCR is a complicated place

of

equipment.

It

contains many belts, rollers, heads etc., which

become worn, and deteriorate

as

time goes by,

causing trouble. Dust and

dirt

will also impede the

proper

functioning

of

the machine. In light

of

this,

it

is

very

important

that

overall maintenance

be

done according

to

the maintenance

chart

to

maintain

the functions

of

the VCR, and

to

avoid

accidental problems. This maintenance should also

be

performed

after

any repairs are done

on

the

equipment.

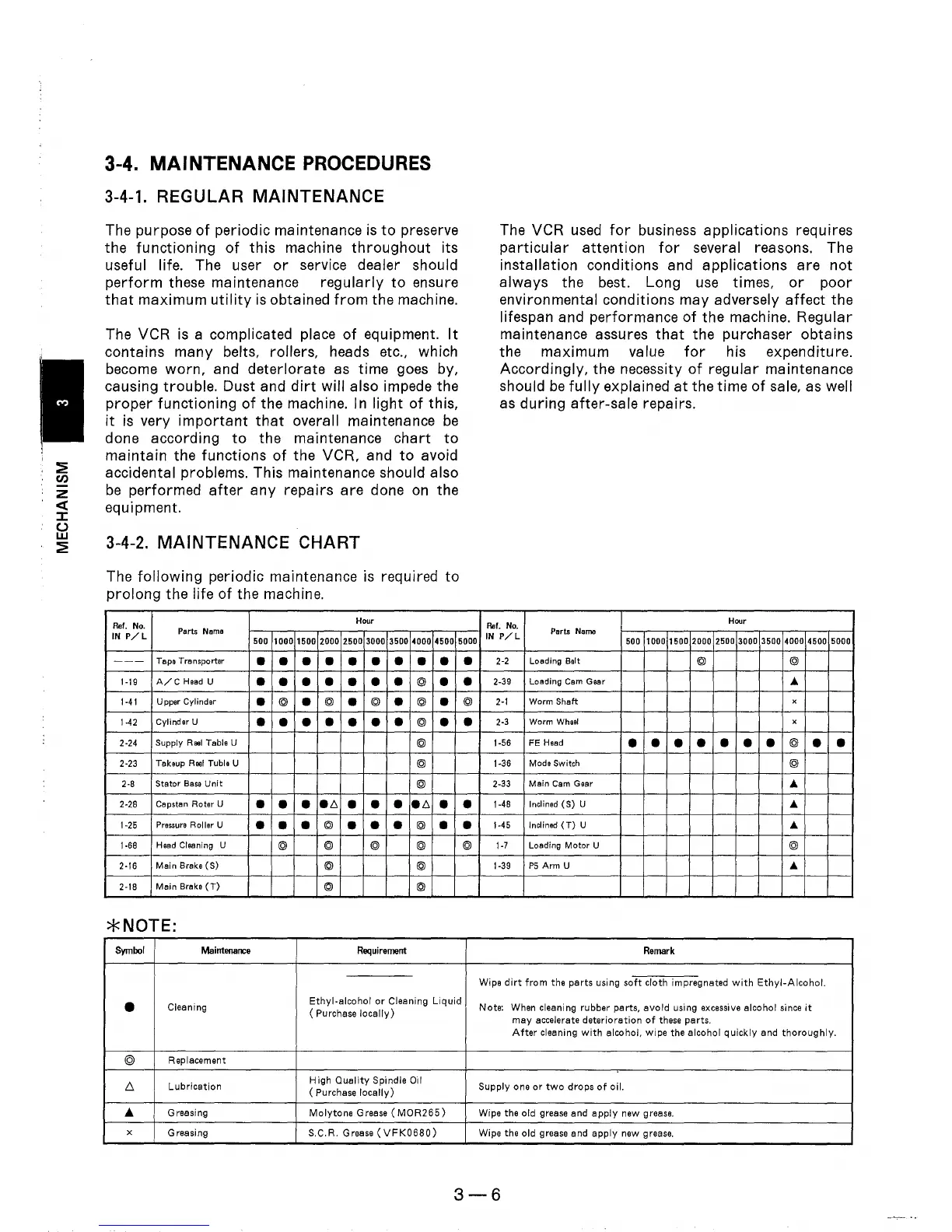

3-4-2. MAINTENANCE CHART

The

following

periodic maintenance is required

to

prolong

the life

of

the machine.

Ref.

No.

Hour

Parts

Noma

IN

P/L

500

1000

1500 2000 2500 3000 3500 4000 4500

5000

---

Tape Transporter

•

• •

•

•

•

•

•

•

•

1-19

A/C

Head U

•

• • •

•

• •

@

•

•

1-41

Upper

Cylinder

•

@

•

@

•

@

•

@

•

@

1-42

Cylind.r

U

• • • • • •

•

@

•

•

2-24

Supply

Reel

Tabl.

U @

2-23

Tak.up

Reel

Tubl.

U

@

2-8

Stator

Ba

..

Unit

@

2-28

Capstan

Roter U

• • •

.6

• • •

.6

• •

1-25

Pressure

Roller

U

•

•

•

@

•

• •

@

• •

1-68

Heed Cleening U @

@

@ @

@

2-16

Main

Brak.

(S)

@

@

2-18

Main

Brak.

(T)

@

@

*NOTE:

Symbol

Maintenance

Requirement

•

Cleaning

Ethyl-alcohol

or

Cleaning Liquid

(

Purchase locally)

@

Replacement

!:::,.

Lubrication

High

Quality Spindle

Oil

( Purchase locally)

..

Greasing Molytone Grease

(MOR265)

x

Greasing

S.C.R. Grease

(VFK0680)

The VCR

used

for

business applications requires

particular

attention

for

several reasons. The

installation conditions and applications are

not

always the best. Long

use

times,

or

poor

environmental conditions may adversely affect the

lifespan and performance

of

the machine. Regular

maintenance assures

that

the purchaser obtains

the maximum value

for

his expenditure.

Accordingly, the necessity

of

regular maintenance

should

be

fully

explained

at

the time

of

sale,

as

well

as

during

after-sale repairs.

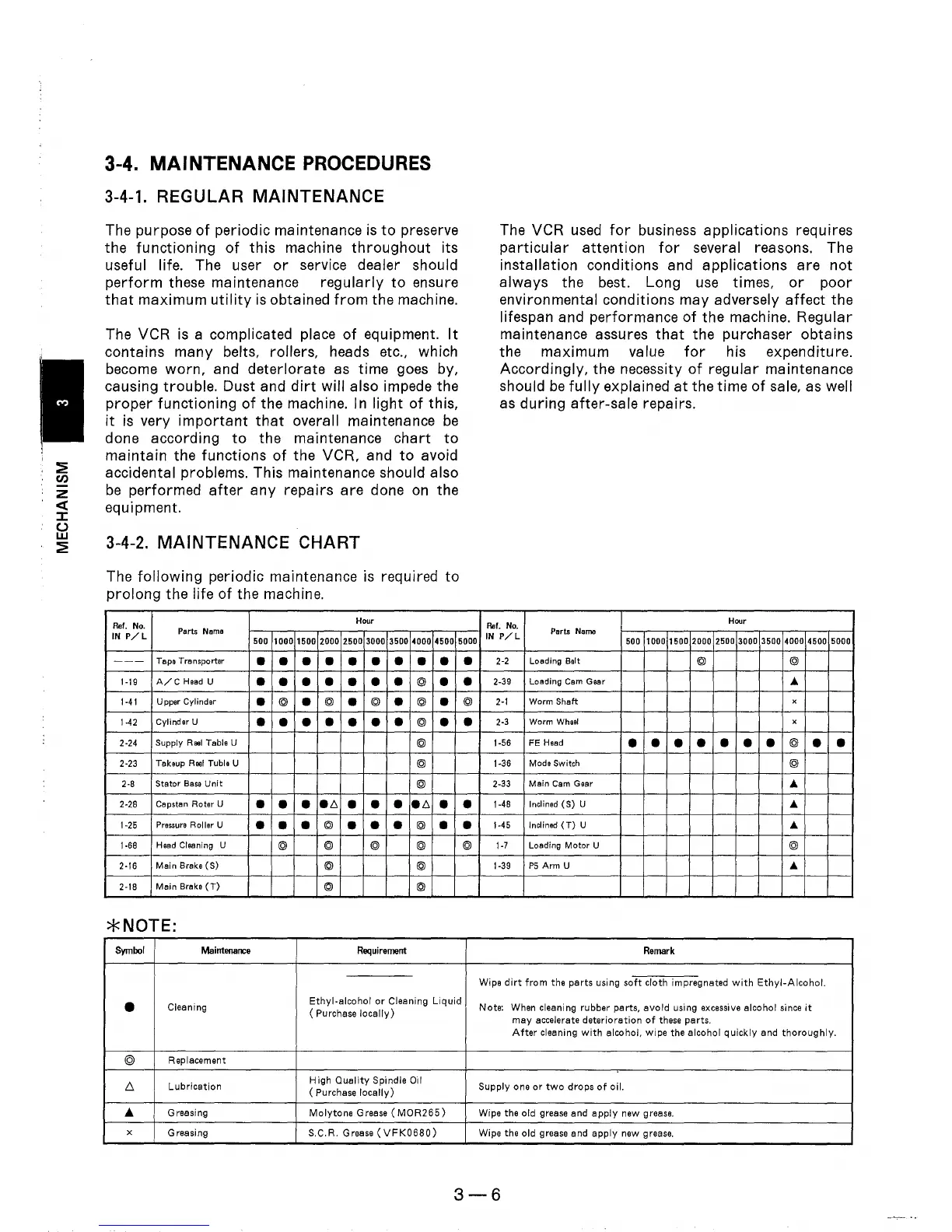

Ref.

No.

Hour

IN

P/L

Ports Namo

500 1000

1500

2000

2500 3000

3500

4000

4500

5000

2-2

Loading

B.lt

@ @

2-39

Loading

Cam Gear

...

2-1

Worm

Shaft

x

2-3

Worm

Wheel

x

1-56

FE

H.ad

•

•

•

• •

•

•

@

•

•

1-36

Mod.

Switch @

2-33

Main

Cam

Gear

...

1-48

Inclin.d

(S)

U

...

1-45

Inclined

(T)

U

...

1-7

Loading Motor U

@

1-39

P5

Arm U

...

Remark

Wipe

dirt

from the

parts

using

soft

cloth impregnated with Ethyl-Alcohol.

Note:

When

cleaning rubber parts, avoid using excessive alcohol since it

may accelerate deterioration of these parts.

After cleaning with

alcohol, wipe the alcohol quickly and thoroughly.

Supply one or

two

drops of oil.

Wipe

the old grease and apply

new

grease.

Wipe

the old grease and apply

new

grease.

3-6

Loading...

Loading...