3-7-8.

ASSEMBLY PROCEDURES OF

CONNECTION

GEAR

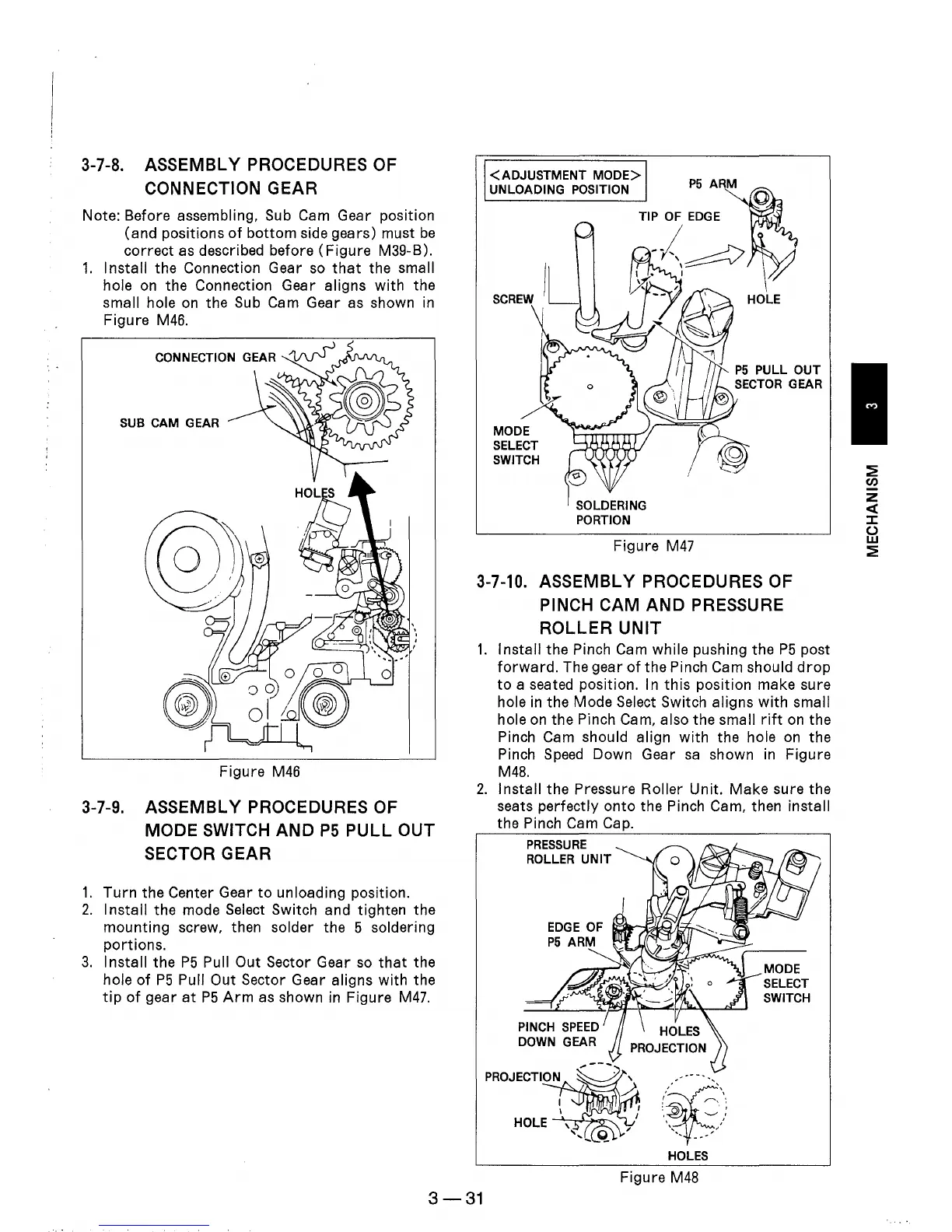

Note: Before assembling, Sub Cam Gear position

(and positions

of

bottom

side gears) must

be

correct as described before

(Figure

M39-B).

1.

Install the Connection Gear

so

that

the small

hole

on

the Connection Gear aligns with the

small hole

on

the Sub Cam Gear as shown

in

Figure

M46.

SUB CAM GEAR

Figure

M46

3-7-9.

ASSEMBLY PROCEDURES OF

MODE

SWITCH

AND

P5

PULL

OUT

SECTOR GEAR

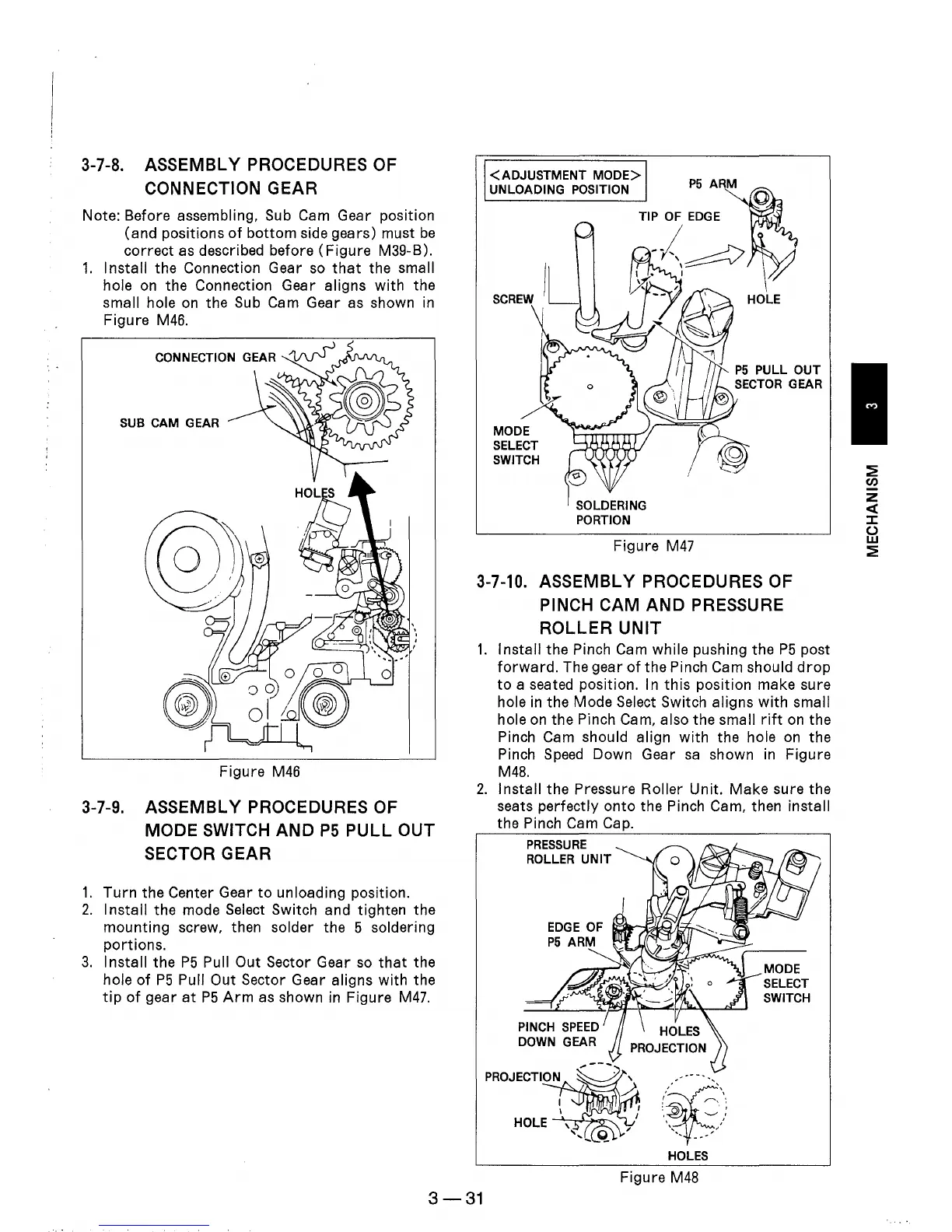

1.

Turn

the Center Gear

to

unloading position.

2.

Install

the mode Select Switch and tighten the

mounting screw, then solder the 5 soldering

portions.

3.

Install the

P5

Pull Out Sector Gear

so

that

the

hole

of

P5

Pull Out Sector Gear aligns with the

tip

of

gear

at

P5

Arm

as

shown

in

Figure

M47.

<ADJUSTMENT

MODE>

UNLOADING POSITION

MODE

SELECT

SWITCH

SOLDERING

PORTION

P5

ARM

Figure

M47

3-7-10.

ASSEMBLY PROCEDURES OF

PINCH

CAM

AND

PRESSURE

ROLLER

UNIT

1.

Install the Pinch Cam while pushing the

P5

post

forward.

The gear

of

the Pinch Cam should

drop

to

a seated position. In

this

position make sure

hole

in

the Mode Select Switch aligns

with

small

hole

on

the Pinch Cam, also the small

rift

on

the

Pinch Cam should align

with

the hole on the

Pinch

Speed

Down Gear

sa

shown

in

Figure

M48.

2.

Install the Pressure Roller Unit. Make sure the

seats perfectly

onto

the Pinch Cam, then install

the Pinch Cam Cap.

PRESSURE

ROLLER

UNIT

PROJECTION

HOLES

Figure

M48

MODE

SELECT

SWITCH

3-31

~

CIJ

z

«

::z::

()

w

~

Loading...

Loading...