i:l!!

en

z

«

:c

u

w

:l!!

3-5-7. REPLACEMENT OF THE

INCLINED BASE (S),(T)

Supply

Side

1.

Unscrew a screw (I) and remove the head

cleaning plate unit

as

shown in Figure M16-A.

2.

Unscrew the 2 screws (J) and remove the post

stopper.

CUT WASHER

DD CYLINDER

HEAD

CLEANING

PLATE

UNIT

Figure M16-A

3.

Remove the

P2

post unit from loading arm (5)

as

shown

in

Figure M 16-B.

SECTOR

GEAR

P2

POST

UNIT

o

LOADING GEAR

(T)

LOADING GEAR

(s)

Figure M16-B

4.

Pull out the Inclined base (5) from loading base.

5.

The new inclined base unit can be reinstalled by

reversing the removal procedure.

Note:

Install post stopper pusing the arrow direction

(A),(B)

as

shown

in

Figure M16-A.

After re-installing the inclined base

(5)

confirmation of tape interchangeability and

P2,

P3 posts adjustments are required.

Take-up

Side

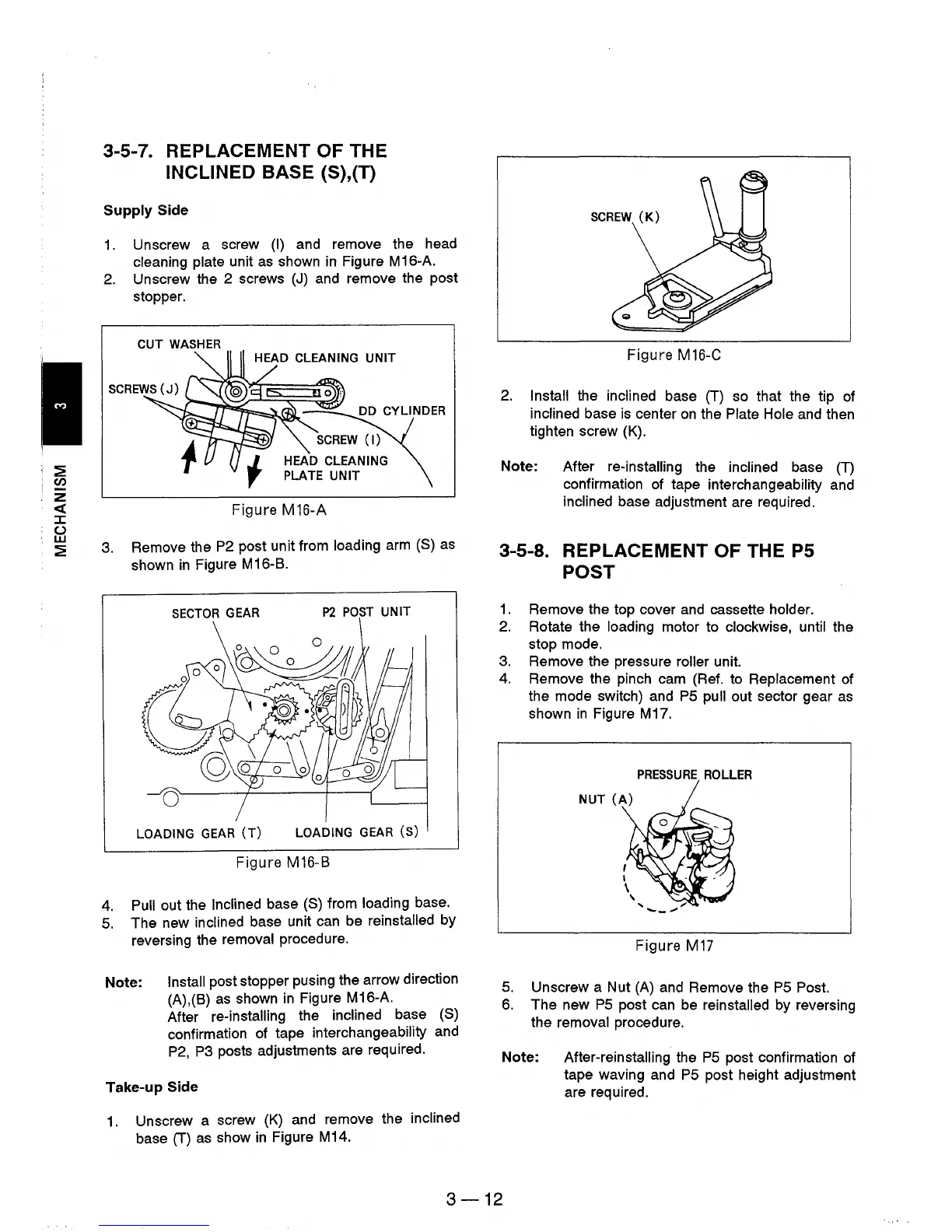

1.

Unscrew a screw

(K)

and remove the inclined

base (T)

as

show

in

Figure M14.

Figure M16-C

2.

Install the inclined base (T) so that the tip of

inclined base

is

center

on

the Plate Hole and then

tighten screw (K).

Note: After re-installing the inclined base

(T)

confirmation of tape interchangeability and

inclined base adjustment are required.

3-5-8. REPLACEMENT OF THE

P5

POST

1.

Remove the top cover

and

cassette holder.

2.

Rotate the loading motor to clockwise, until the

stop mode.

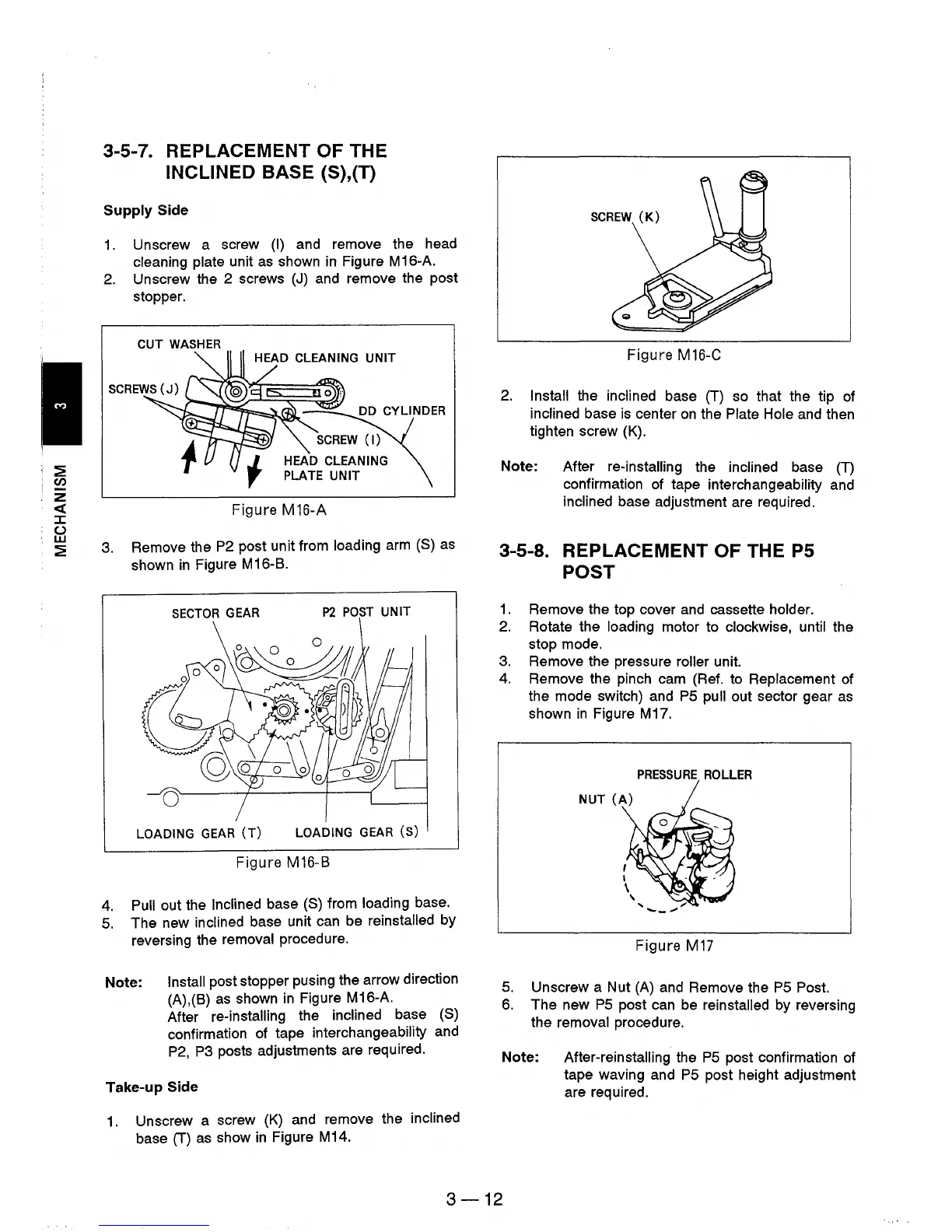

3.

Remove the pressure roller unit.

4.

Remove the pinch cam (Ref. to Replacement of

the mode switch) and

PS

pull out sector gear

as

shown

in

Figure M17.

PRESSURE

ROLLER

Figure

M17

5.

Unscrew a Nut

(A)

and Remove the

PS

Post.

6.

The new

PS

post can be reinstalled by reversing

the removal procedure.

Note: After-reinstalling the

PS

post confirmation of

tape waving and

PS

post height adjustment

are required.

3-12

Loading...

Loading...