~

en

,Z

«

J:

()

w

.;2

3-7. ASSEMBLY AND ADJUSTMENT

PROCEDURES

OF MECHANISM

The mechanism

of

this

model

is

mostly engaged

to

the System Control Circuit,

through

the mode

select switch. Therefore the relation between the

mode select switch and the cam gear decides all

further

mechanical movement

of

the mechanical

parts

such as levers, gears, rollers and

so

on.

If

these

parts

are

not

fixed properly, the

unit

will

be

unloaded

or

compulsorily stopped. And

it

will

result being damaged

at

any mechanical

or

electrical parts. The overall mechanical condition

(alignment)

of

bottom

and

top

view are shown

in

Figure

M39-A and Figure M39-B. This mechanical

adjustment is performed

in

the STOP mode.

3-7-1.

CONFIRMATION

OF

ALIGNMENT

CONDITION

1.

Remove the Loading Belt.

2.

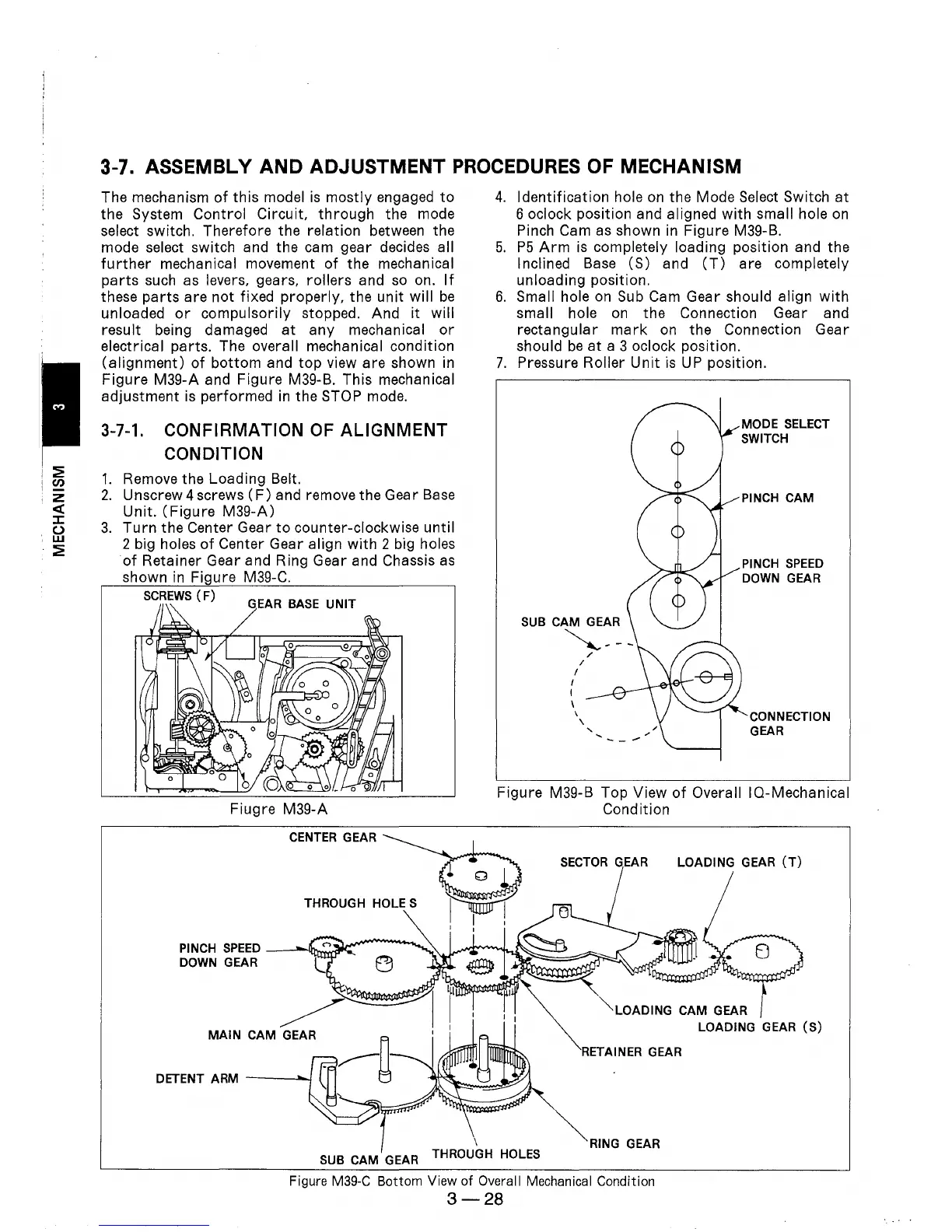

Unscrew 4 screws

(F)

and remove the Gear

Base

Unit.

(Figure

M39-A)

3.

Turn

the Center Gear

to

counter-clockwise until

2 big holes

of

Center Gear align with 2 big holes

of

Retainer Gear and Ring Gear and Chassis

as

shown

in

Figure M39-C.

SCREWS

(F)

GEAR

BASE

UNIT

Fiugre M39-A

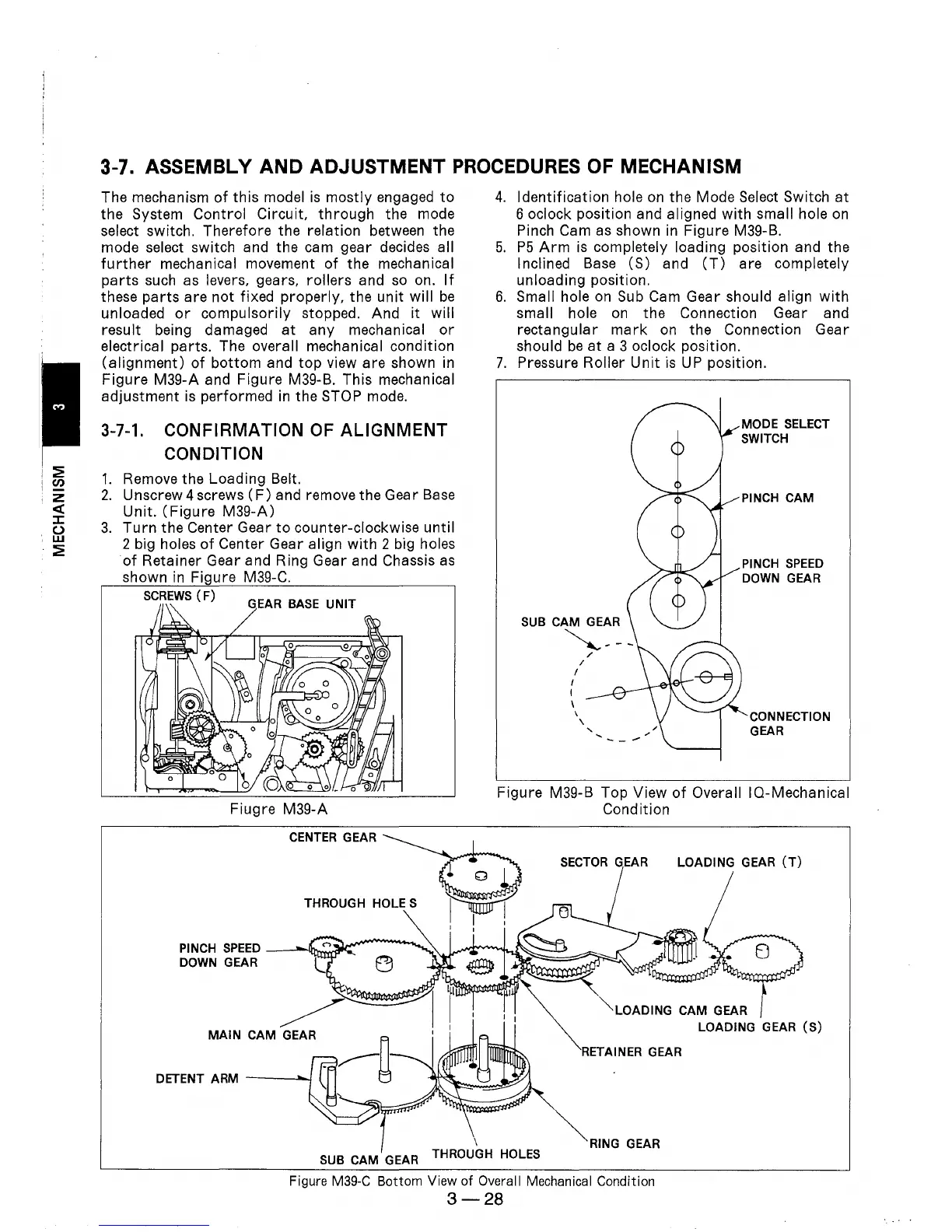

CENT

ER

GEAR

PINCH

SPEED

---I[h.,.,~""

DOWN GEAR

DETENT ARM

--~

\

4.

Identification hole

on

the Mode Select Switch

at

6 oclock position and aligned with small hole

on

Pinch Cam

as

shown

in

Figure M39-B.

5.

P5

Arm

is completely loading position and the

Inclined

Base

(S) and

(T)

are completely

unloading position.

6.

Small hole

on

Sub

Cam Gear should align

with

small hole

on

the Connection Gear and

rectangular

mark

on

the Connection Gear

should

be

at

a 3 oclock position.

7.

Pressure Roller

Unit

is

UP

position.

SUB CAM GEAR

~---

I

I

\

/

I

\

\

/

"

'"

--

..--

PINCH

CAM

PINCH

SPEED

DOWN GEAR

CONNECTION

GEAR

Figure M39-B Top View

of

Overall IQ-Mechanical

Condition

SECTOR

GEAR LOADING GEAR

(T)

"'-LOADING

CAM GEAR

LOADING GEAR

(S)

RETAINER GEAR

~RING

GEAR

SUB CAM GEAR THROUGH HOLES

Figure

M39-C

Bottom View

of

Overall Mechanical Condition

3-28

Loading...

Loading...