9-32 Function Parameters

AC10 Inverter

9.6 Auxiliary Functions

F600 DC Braking Function Selection

0: Disabled

1: Braking before starting

2: Braking during stopping

3: Braking during starting

and stopping

F601 Initial Frequency for DC Braking (Hz)

F602 DC Braking efficiency before Starting

F603 DC Braking efficiency During Stop

F604 Duration of Braking Before Starting (s)

F605 Duration of Braking During Stopping (s)

When F600=0, DC braking function is disabled.

When F600=1, braking before starting is

valid. After the right starting signal is input,

inverter starts DC braking. After braking is

finished, inverter will run from the initial

frequency.

In some applications, such as fan, motor is

running at a low speed or in a reverse

status, if inverter starts immediately, OC

malfunction will occur. Adopting “braking

before starting” will ensure that the fan

stays in a static state before starting to

avoid this malfunction.

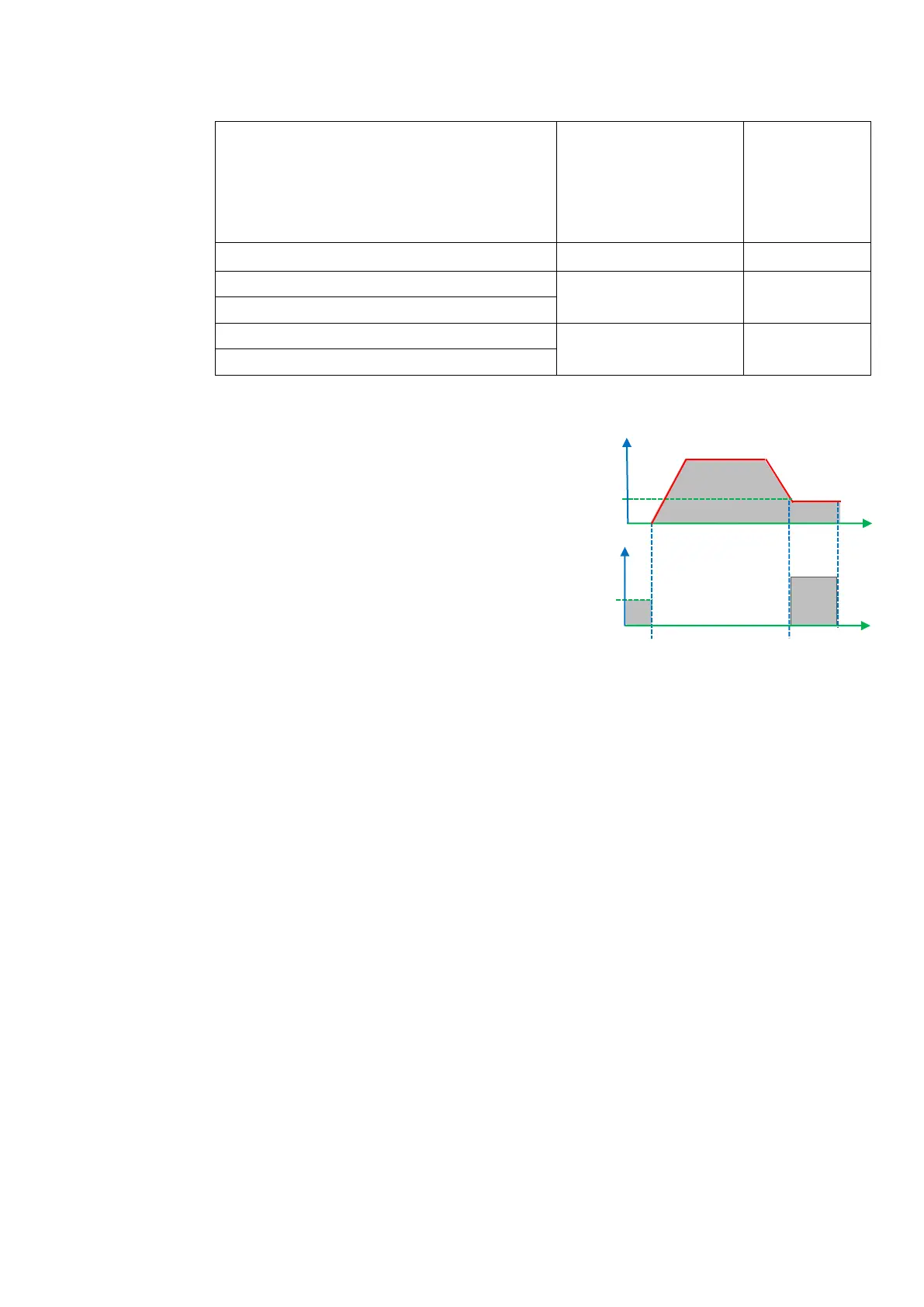

Figure 9-11 DC Braking

During braking before starting, if “stop” signal is given, inverter will stop by deceleration time.

When F600=2, DC braking during stopping is selected. After output frequency is lower than the

initial frequency for DC braking (F601), DC braking will stop the motor immediately

During the process of braking during stopping, if “start” signal is given, DC braking will be

finished and inverter will start.

If “stop” signal is given during the process of braking during stopping, inverter will have no

response and DC braking during stopping still goes on.

Parameters related to “DC Braking”:

a) F601: Initial frequency of DC-braking. DC braking will start to work as inverter’s output

frequency is lower than this value.

b) F604: Braking duration before starting. The length of time for DC braking before inverter

starts

c) F605: Braking duration when stopping. The length of time for DC braking while inverter

stops.

Note: Excessive DC braking can damage an AC motor. At low speeds a motor without forced

air cooling (like a TEBC motor would) does not have sufficient self-cooling, and may be easily

over-heated. Do not set DC braking voltage (F602, F603) too high or set DC braking time

(F604, F605) too long. DC braking is not recommended in an application where there will be

more than 4 stops per hour.

DC braking, as shown in Figure 9-11.

Corresponding Frequency (Hz)

Loading...

Loading...