13 - 46

Adjustment

49-112

24V = 4% ED

49-111

49-110

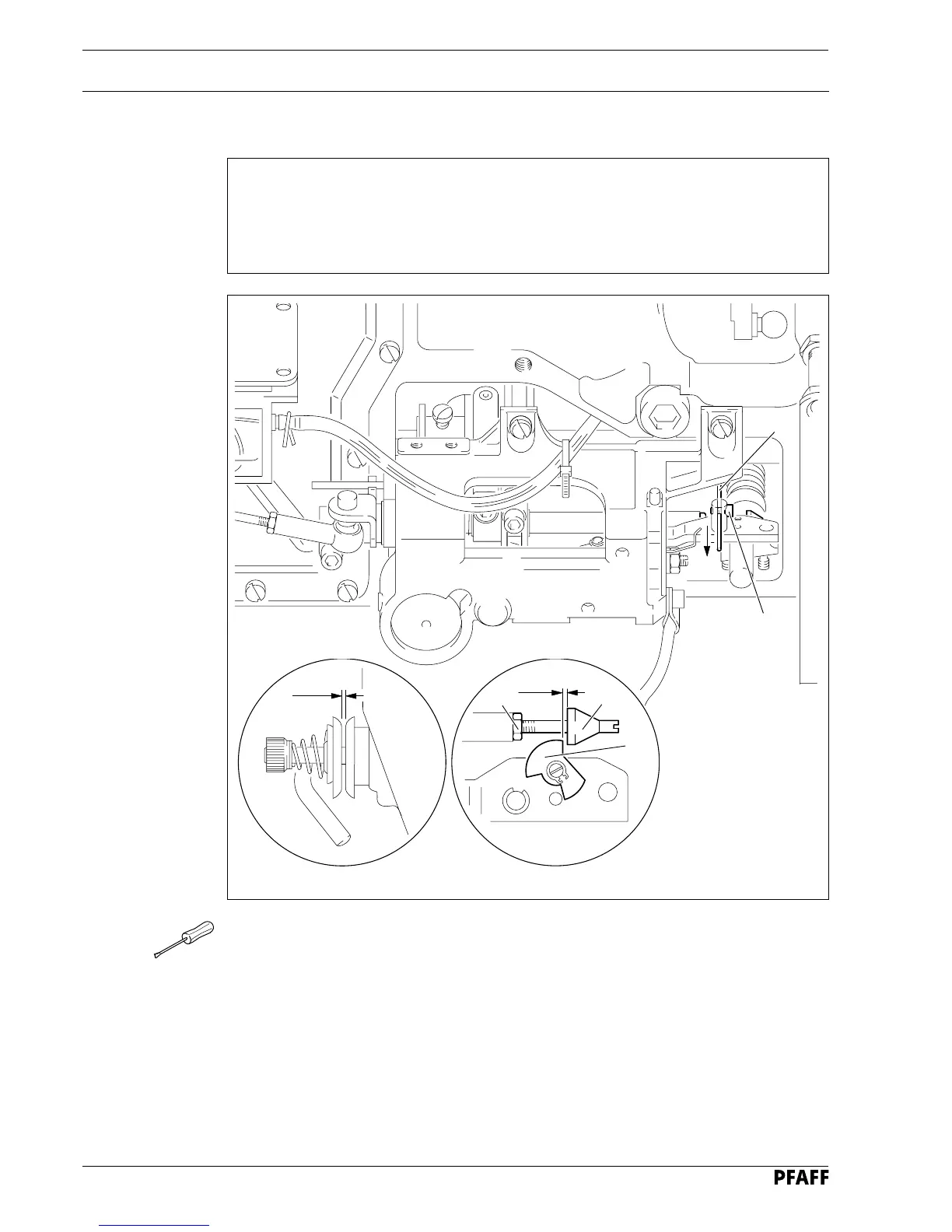

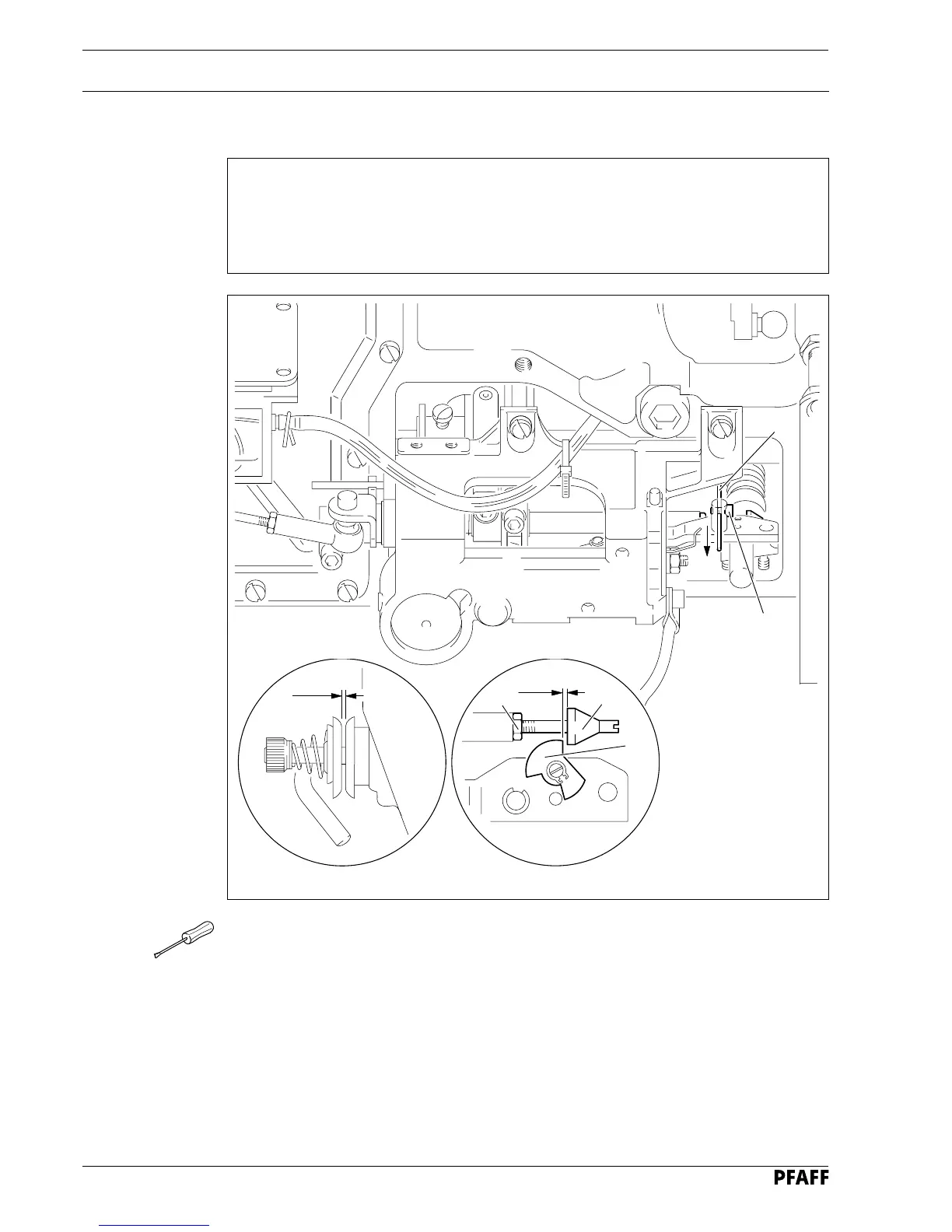

13.06.13 Tension release of needle thread

Requirements

1. When the thread trimming unit is in resting position, trip 5 should be engaged and at a

distance of 0.5 mm from the release cone 1.

2. When trip 5 is positioned at the highest point of the release cone 1, the tension disks

should be spaced at a mimimum of 0.5 mm from each other.

● Turn release cone 1 (nut 2) in accordance with requirement 1.

● Lower the presser foot onto the needle plate.

● Pull out the thread from between the tension disks.

● Pull down linkage 3 (screw 4) until you feel it stop.

● Position the needle bar at b.d.c and activate the engaging lever manually.

● Turn the hand wheel until trip 5 is positioned at the highest point of release cone 1.

● The tension disks now have to be spaced at a minimum of 0.5 mm from each other.

● Bring the rock shaft back to its starting position by turning the hand wheel.

● Trip 5 now must be engaged, the needle thread must be under full tension.

● Grease release cone 1 slightly.

Fig. 13 - 45

0.5 mm

0.5 mm

2

1

5

4

3

Loading...

Loading...