Operation

61-900040-000 Rev. Date: 01/22 3-3

The oil output can be changed by replacing the installed foams with the alternate

wicking foams that were shipped with the machine. For more information about

changing the oil output, refer to Section 6 - Determining the Oiling Pattern.

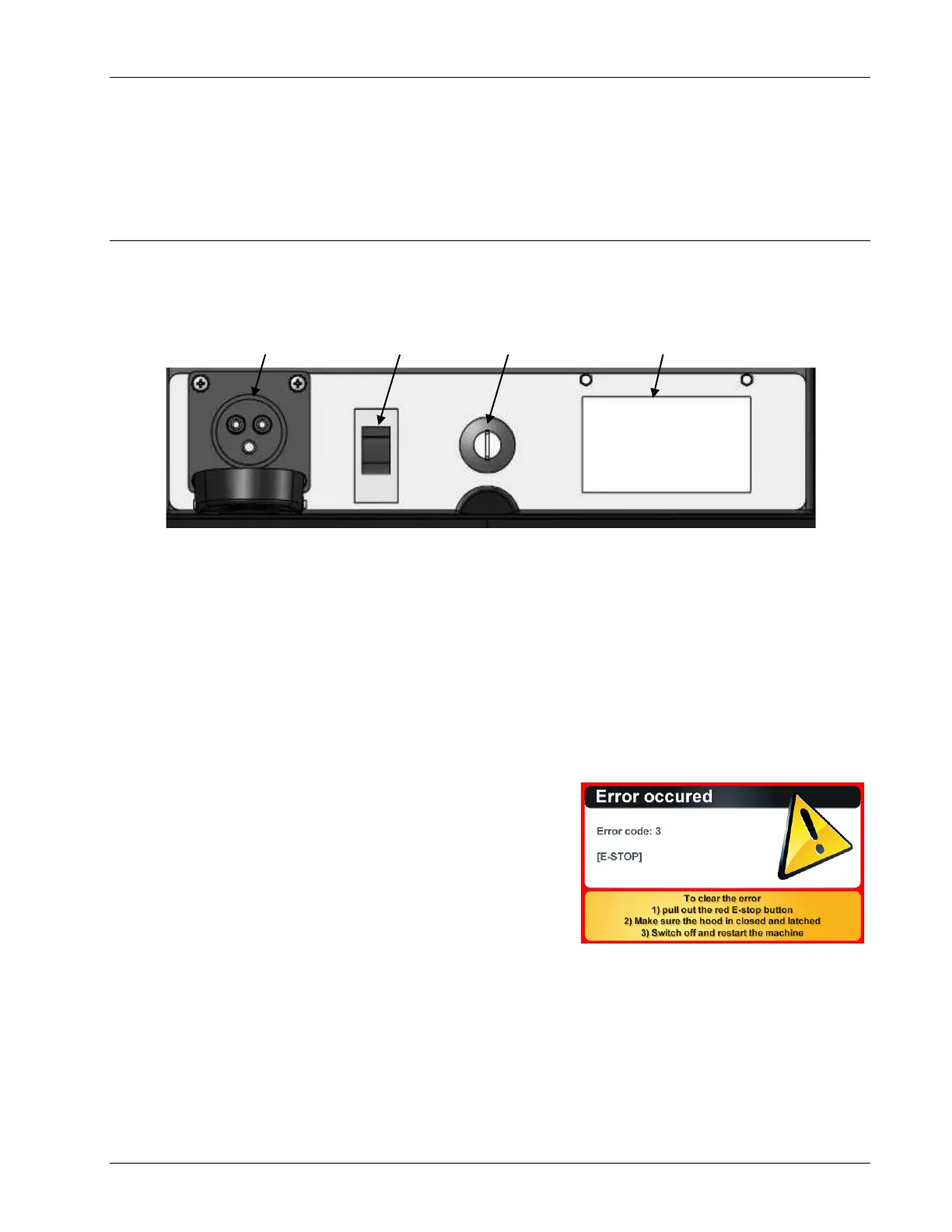

3.2 THE PHOENIX LT4 LANE MACHINE CONTROLS

The Phoenix LT4 Lane Machine features a touch screen, making it very simple to operate.

The control panel, shown in Figure 3- 2, features four main components: the power inlet,

power switch, E-STOP Button, and the touch screen.

The power inlet is a blue receptacle where the power cable is connected to the machine.

The large blue receptacle and its mating connector are designed to fit together in only one

way. The machine must only be connected to a grounded 110V or 240V outlet, depending

on the machines' voltage rating.

The power switch turns power on and off to the machine. This style switch is also a circuit

breaker and provides overcurrent protection (20 amp for 110V, 14 amp for 240V) to the

machine. The power switch does not start any of the machine's operations but it does

energize the vacuum solenoid to lift it off of the lane.

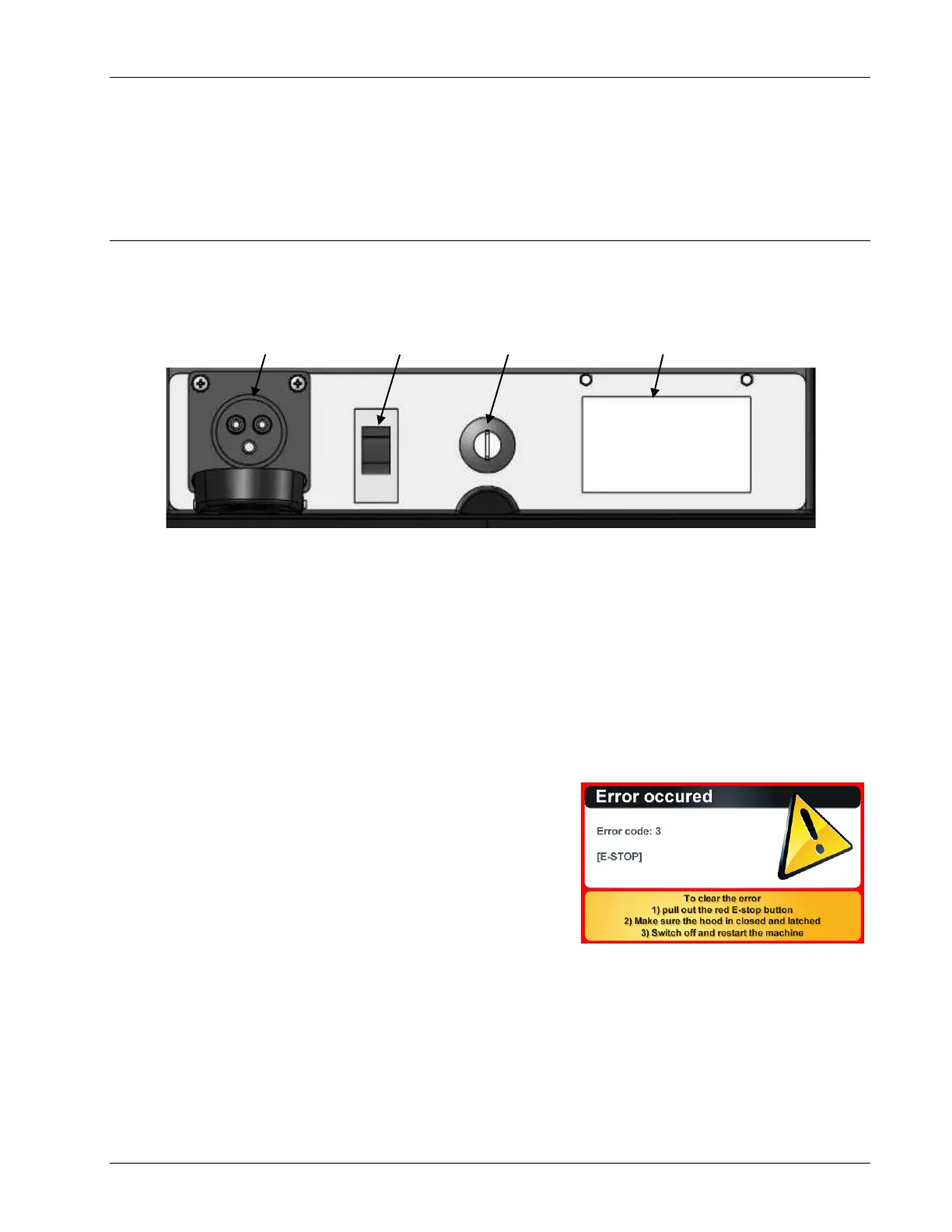

The E-STOP is a large red button that stops all

machine operations when it is pressed. Pressing the

E-STOP will not power off the machine but will

display the E-STOP error message, shown in Figure

3- 3, on the screen. After being activated, it must be

reset by inserting the key and turning (the button

should pop back out) then power cycling the machine

before operation can continue. When the E-STOP

button is out, a yellow sticker will be visible behind the

button. When it is pressed in, no yellow will be visible.

Loading...

Loading...