Phoenix LT4 Lane Machine Operation, Maintenance, and Parts Manual

4-14 Rev. Date: 01/22 61-900040-000

7. Install the wicking foam that was removed in Step 5 in the other end of the oil

tank. Install it with its unused side facing out.

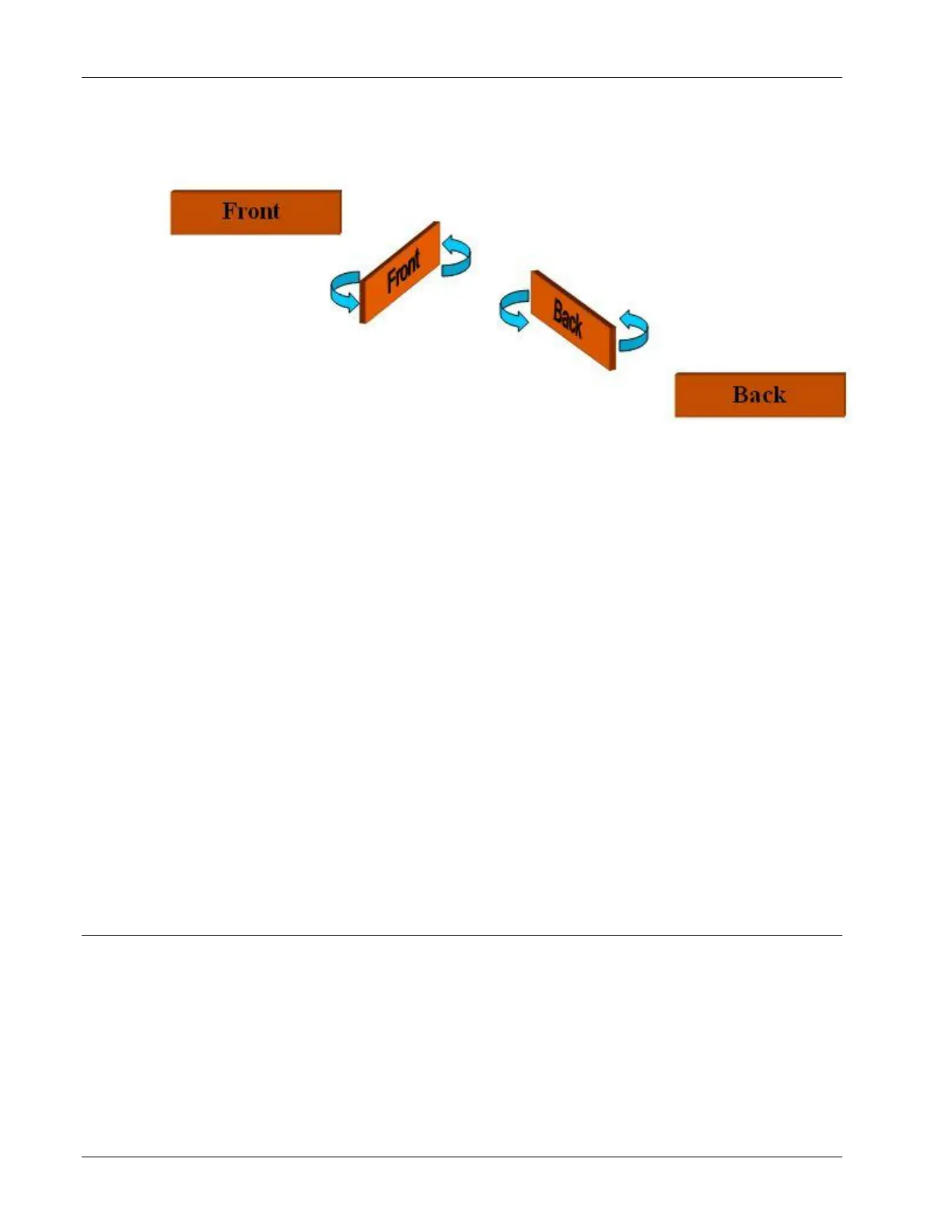

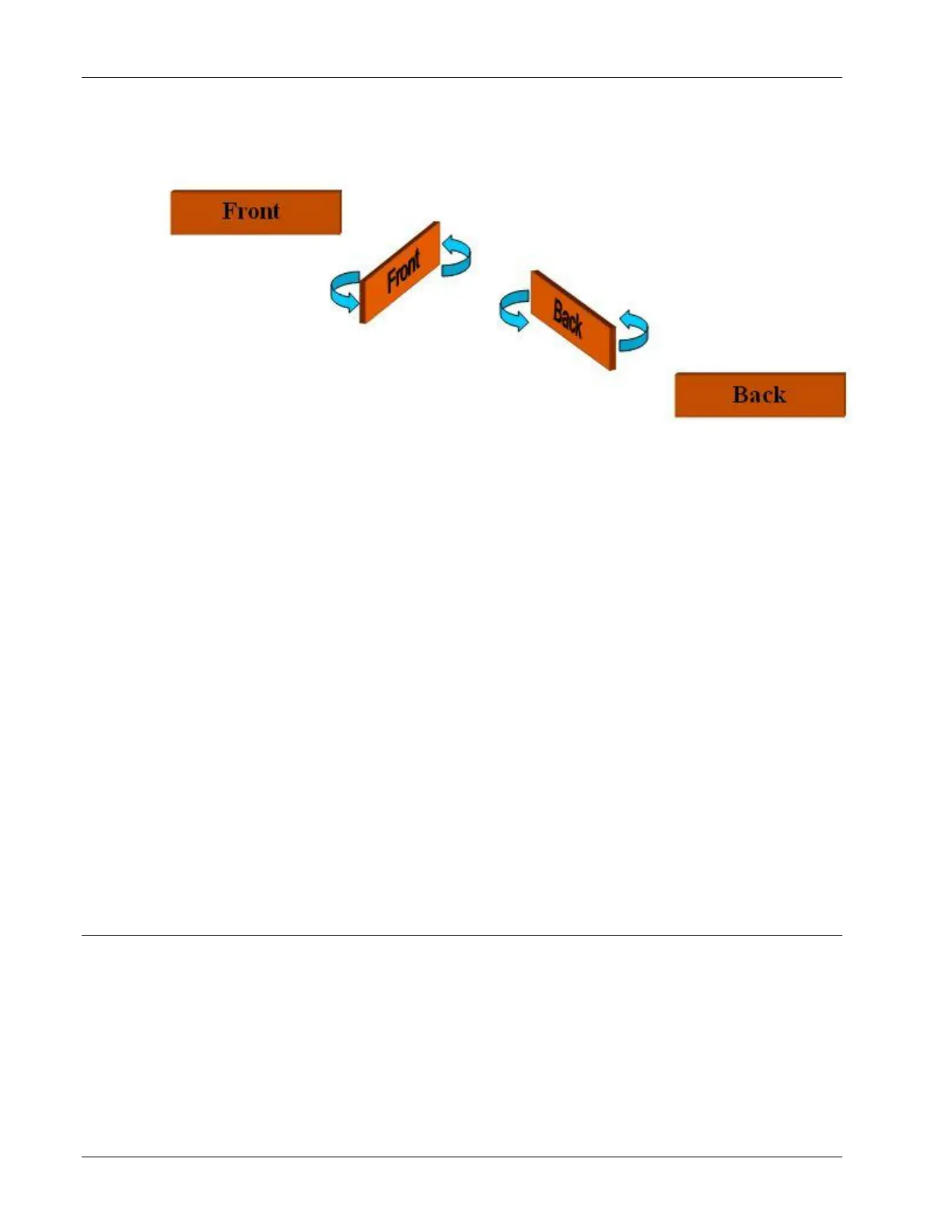

Figure 4- 12

8. Repeat the operation for the remaining wicking foams. They can be reinstalled

in their original locations. Ensure the wicking foams line up evenly across the

top, with 1½ inches of foam showing above the tray edge, and that they are

firmly seated in the oil tray.

9. Wipe up any spills immediately with a clean, dry cloth.

10. Tip the oil tank forward against the oil transfer roller, and latch in place with the

oil tank spring. Close and latch the compartment door.

NOTES

After rotating the wicking foams, ensure they are completely saturated with

conditioner before conditioning the lanes.

On the first use after rotating the wicking foams, clean, oil, and buff the first lane

twice to ensure the proper amount of oil is applied.

If using a single piece wicking foam, remove entire wicking foam and flip as shown

in Figure 4- 12.

4.3.3 Lubricating the Chains

The drive chain and sprocket along with the oil transfer roller and its' sprocket should be

lubricated every 135,000 feet. Use a quality 80- to 90-weight gear oil and be sure to wipe

off any excess oil. DO NOT USE GREASE. Perform the steps below with the machine in

the operating position to lubricate the chains and sprockets.

Loading...

Loading...