Phoenix LT4 Lane Machine Operation, Maintenance, and Parts Manual

3-12 Rev. Date: 01/22 61-900040-000

Test Screen. CAUTION: Changes made in settings affect ALL programs and are

immediate once saved. Changes should only be made by advanced users.

o Xfer Speed - The Xfer Speed controls the speed of the transfer roller.

Increasing it will increase the speed while decreasing it slows it down.

Increasing the transfer roller speed increases the amount of oil drawn from

the oil tank wick resulting in an increased volume of oil applied to the lane.

o EOL Delay - EOL Delay stands for End of Lane Delay and controls the delay

for braking once the optical sensor detects the end of the lane. Increasing it

will lengthen the delay while decreasing it will reduce the delay.

o Foul Stop - Foul Stop controls the time, prior to reaching the foul line, that the

drive motor turns off. If it is found that the machine is consistently overrunning

the foul line on multiple lanes, this value should be increased. Likewise, if the

machine is stopping too soon, the value should be decreased.

o Brake Time- This controls the amount of braking applied to the motor to stop

the machine. Increasing it will result in more braking while reducing it will

decrease the amount of braking applied. CAUTION: The brake value should

be set high enough to ensure the machine comes to a complete stop before

the brake is released. Setting the brake time higher than needed will result in

over-braking that can cause the motor to overheat.

3.2.6 Error Messages

The Phoenix LT4 Lane Machine has several monitoring features. When unexpected

conditions occur, an error message will be displayed on the screen. This section is an

overview of the error messages.

NOTE

Before manually moving the machine on the lane, always wait for the vacuum head

to be lifted off of the lane. Moving the machine without the vacuum head lifted could

cause damage to the agitator foam and squeegee.

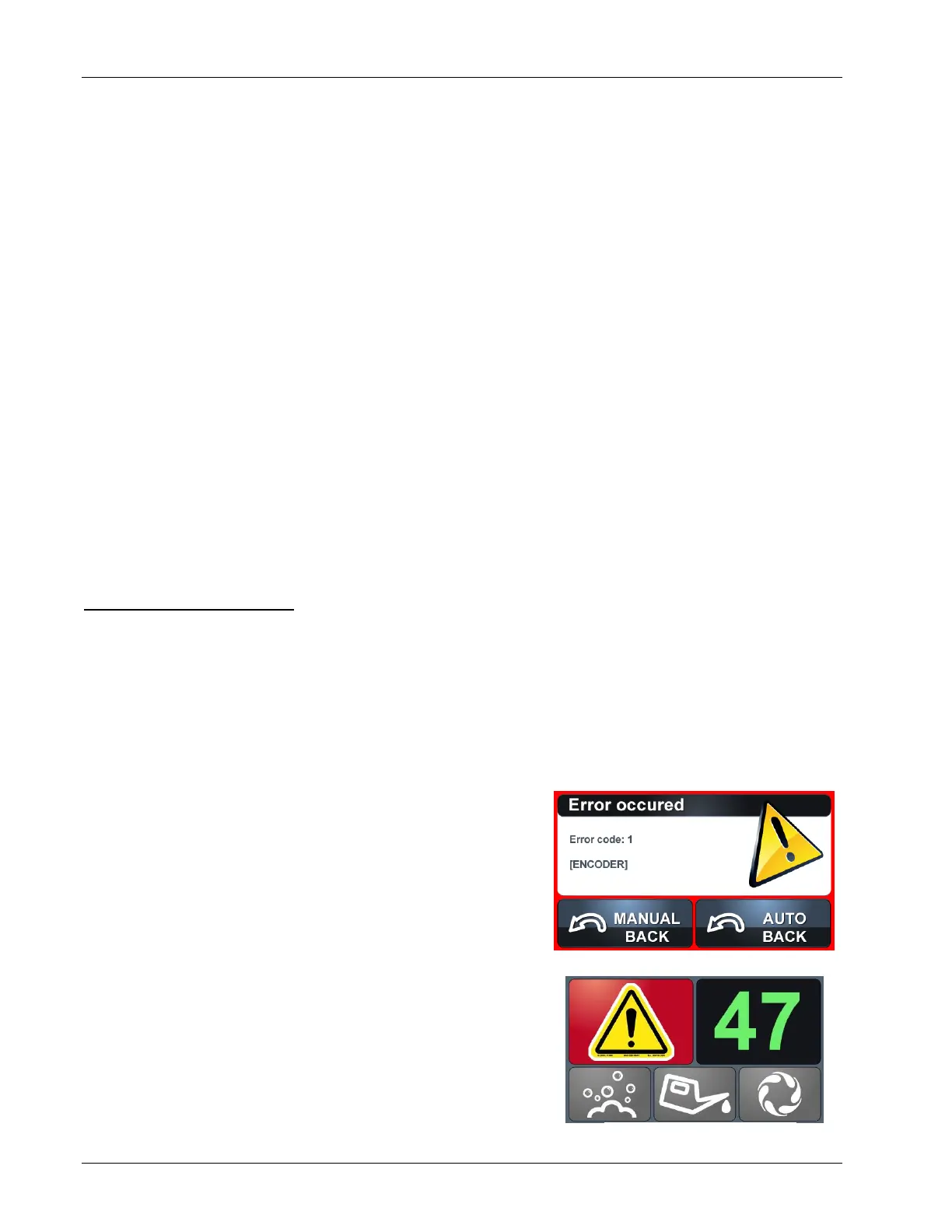

Error Code 1 - Encoder

The Encoder error, shown in Figure 3- 24, will occur if

the encoder does not detect that the machine is

moving. Generally this occurs when the machine gets

stuck due to an anomaly of the lane structure, running

over the power cord, or extremely heavy oil conditions

on the lane. It could also be the result of a drive

system failure or the failure of the encoder itself. When

this error occurs, the machine must be returned to the

foul line and the lane reconditioned. Select the Manual

Back button to manually return the machine to the foul

line. If the machine detects it is being moved, it will

automatically select Manual Return.

Loading...

Loading...