Operation

61-900040-000 Rev. Date: 01/22 3-19

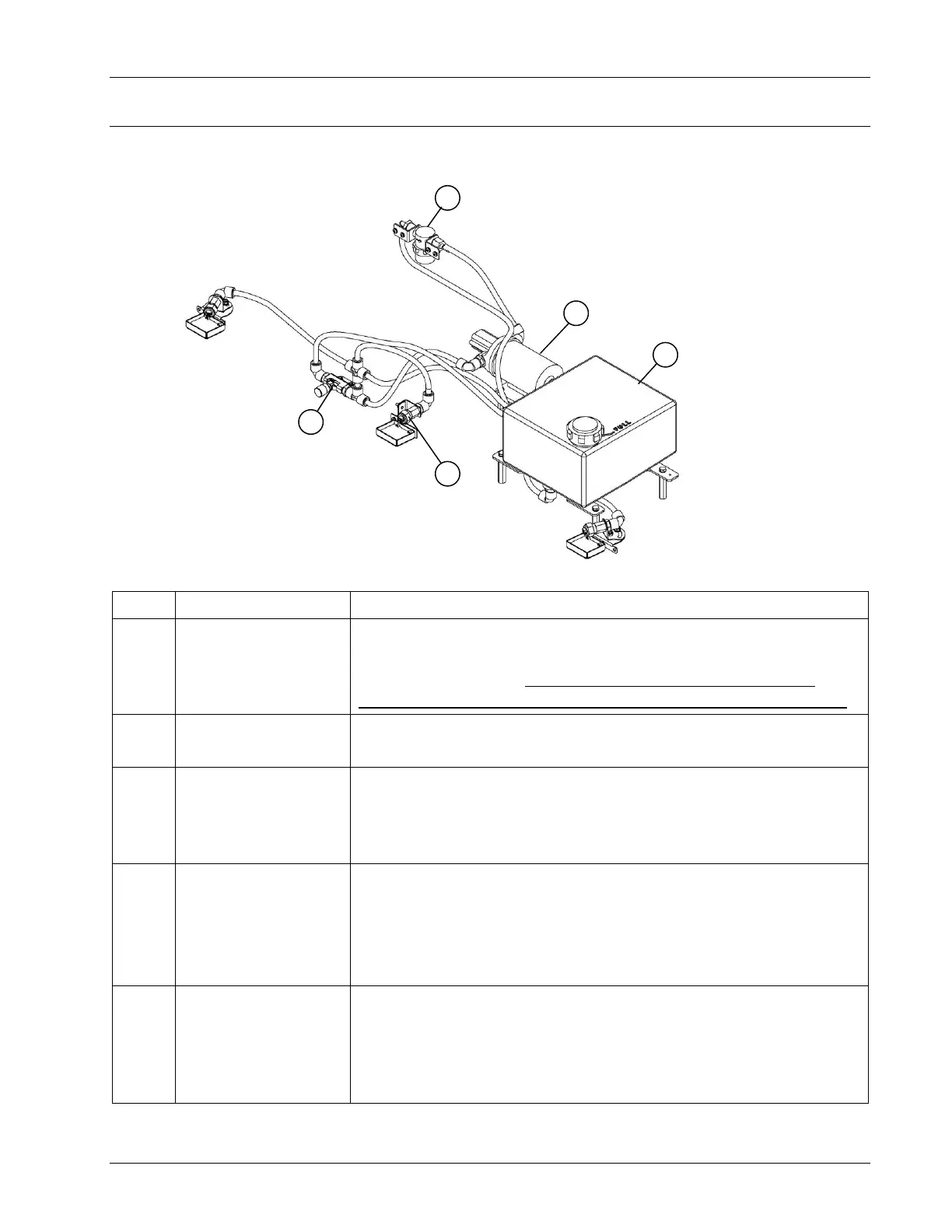

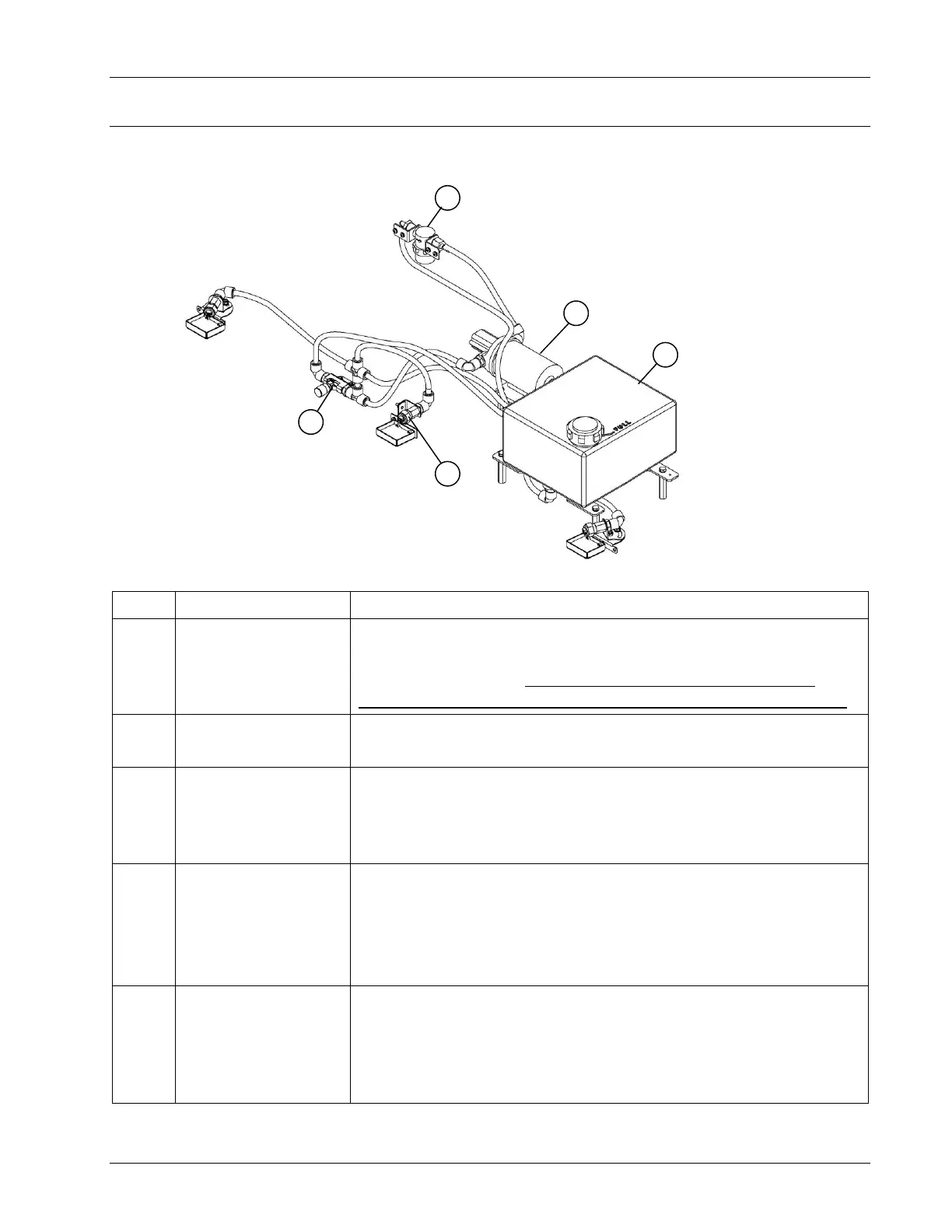

3.6 CLEANING OPERATION COMPONENTS

The components used in the cleaning operation are shown in Figure 3- 38, Figure 3- 39,

and Figure 3- 40 described below in Table 3- 4, Table 3- 5, and Table 3- 6, respectively.

Table 3- 4

This tank holds the cleaning solution. It holds enough to

clean approximately 16 lanes. When placing the machine in

the storage position, ensure the cleaner level is below the

level of the cap or cleaner could drip from the cap’s vent hole.

This pump transfers cleaner from the cleaner tank to the

spray head.

Located on the rear of the waste tank mounting bracket

in the tubing running from the cleaner tank to the cleaner

pump, the filter is designed to strain out any particles that

could lodge in the pump or spray nozzles.

The spray heads distribute the cleaner on the lane and

can be adjusted for both amount of spray, and direction.

Refer to Section 4.3.4 – Adjusting the Cleaner Spray for

instructions on clearing clogs and how to change the

amount of cleaner dispensed from the spray heads.

Cleaner Flow

Control Valve

This manually operated valve is used to control the

amount of cleaner being supplied to the spray heads.

Throttling (closing) the valve increases cleaner flow to

the spray heads. Excess cleaner is routed back to the

cleaner tank.

Loading...

Loading...