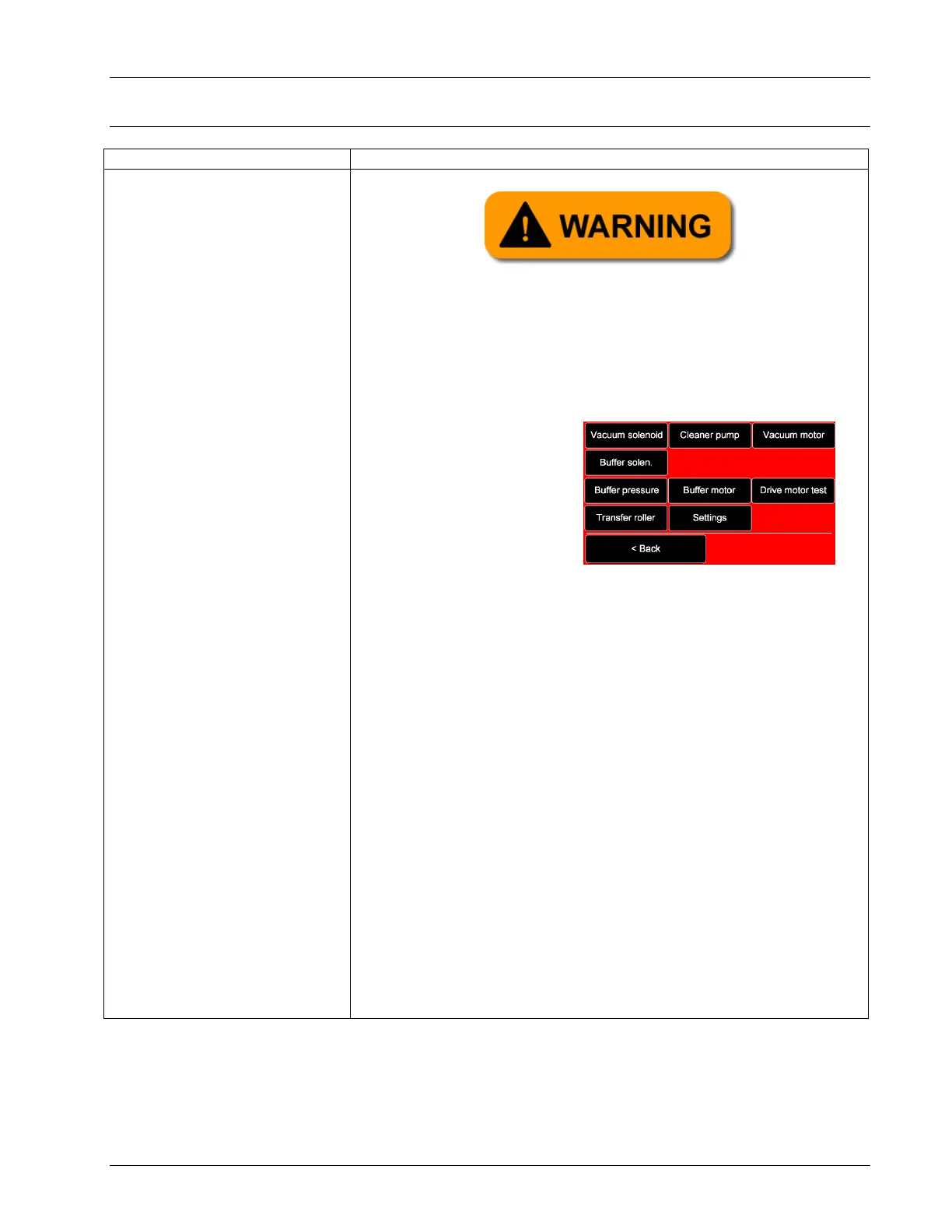

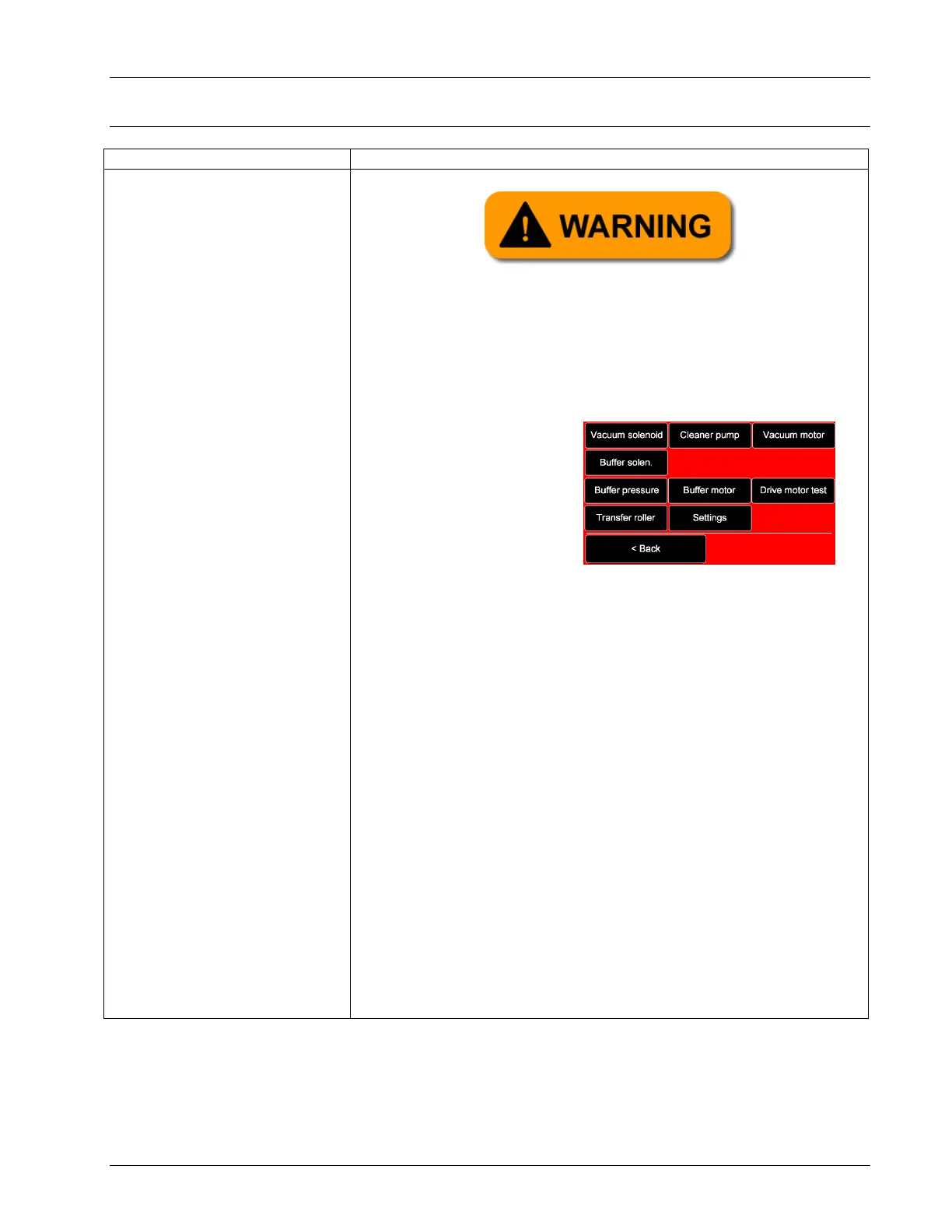

Use extreme care when servicing solenoids. The

surfaces can be very hot and a severe pinching hazard

exists under the hood.

To determine which solenoid might not be fully engaging,

select Test Area from the Test Screen. The test area

(shown) will be

displayed. Press the

vacuum solenoid button

to disengage the vacuum

solenoid. If there is no

change in the hum/buzz,

press the buffer brush

solenoid button. This will engage the two buffer brush

solenoids. By pressing these two buttons and listening for

changes in the hum/buzz, one should be able to determine

which of the three solenoids is not fully engaging.

The particular solenoid that is not fully engaged can also be

found by feeling NEAR the solenoid. A solenoid that is not

fully engaging will feel hot. It will also vibrate as it is making

the sound.

Solenoids that do not fully engage are usually out of

alignment. If a misaligned solenoid is found, turn off power

and unplug machine, loosen the adjustment screws, realign

the solenoid, tighten the screws, and recheck. Any time the

position of a solenoid is adjusted, the vacuum head or buffer

brush, as applicable, will need to be checked for adjustment.

It is also possible that oil or debris has gotten on the

solenoid shaft and is preventing the solenoid from engaging.

Wipe the solenoid shaft with a clean, dry cloth.

If the solenoid continues to buzz or feel hot and adjusting it

does not correct the problem, replace it. Refer to Section 7 -

Parts for part numbers.

Loading...

Loading...