-113-

S

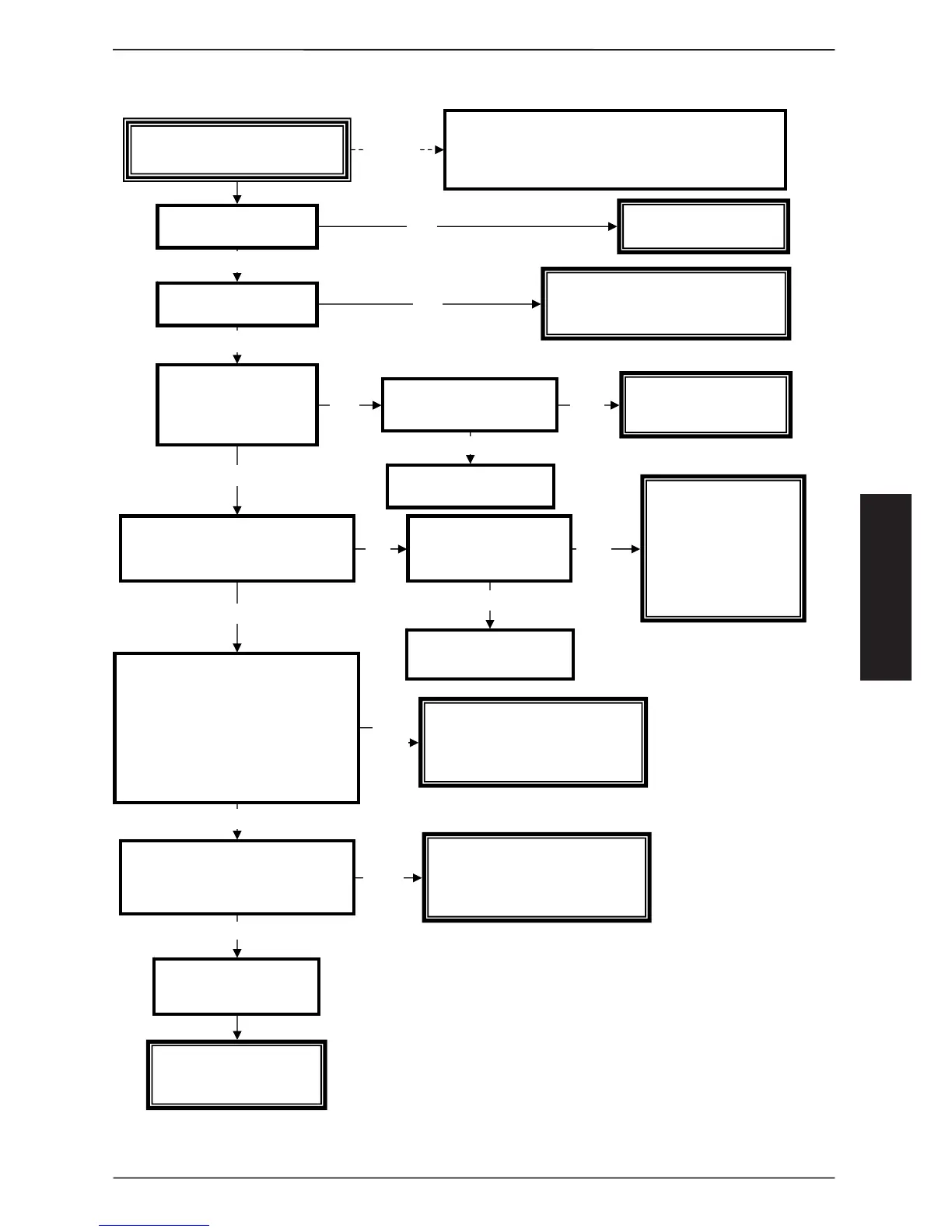

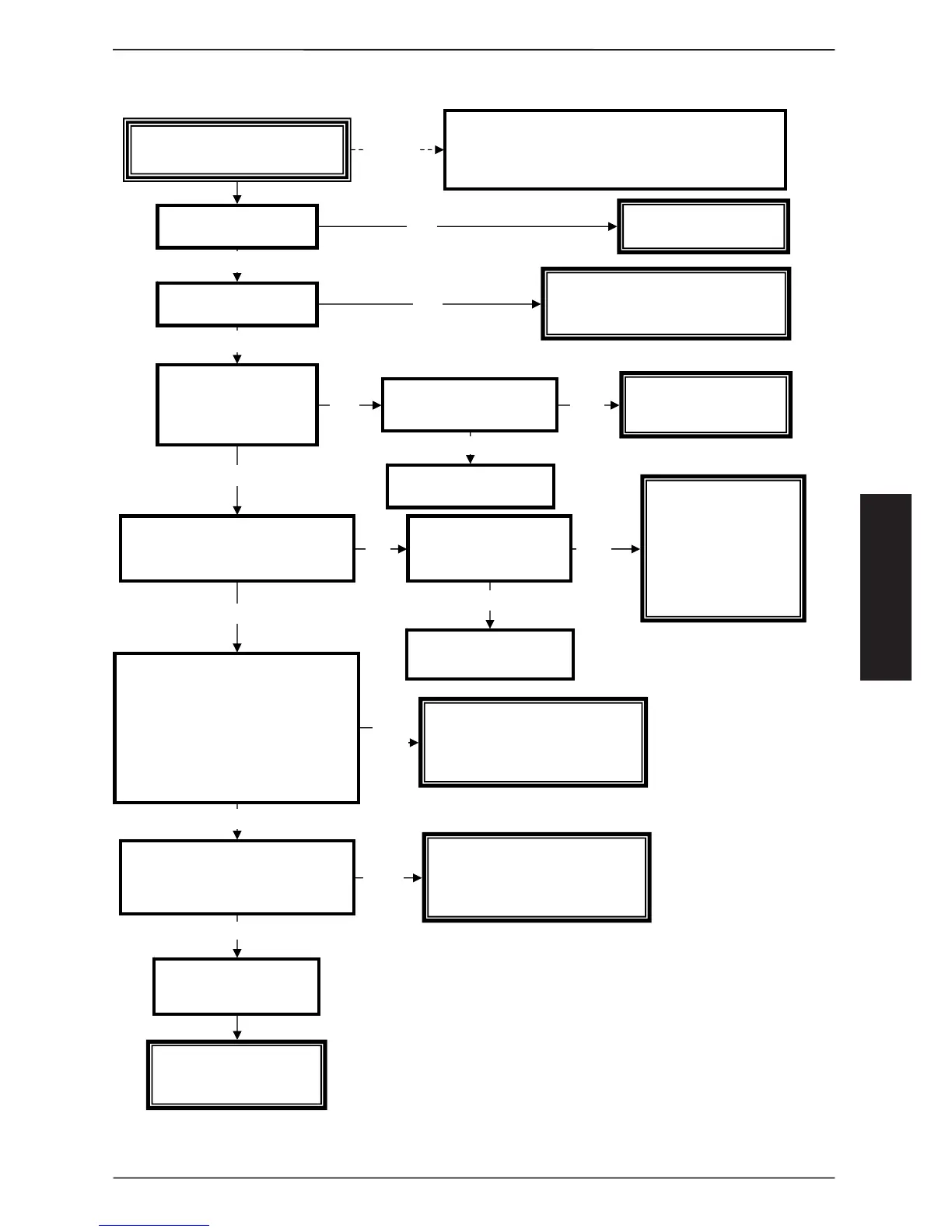

Fault List SCC

Service 25

Activate CleanJet-

Pump (M6) in the

function test.

Is pump running?

Output voltage of I/O pcb

X18 3/4 present

CleanJet pump does not or not enough deliver

enough water (loss of pressure during CleanJet).

Typical indication:

The running time of the program will be exceeded.

Check ball valve and

change if necessary

Indication Service 25

every time unit is switched on

Info

Check pump, cable and

connector, change

defective part

Fuse of I/O pcb or pcb

defective.

yes

no

ctivate solenoid valve quenching

(Y2) in the function test.

Function ok?

Output voltage of I/O

pcb X19/5 present

Test valve, cable and

connector, if any part

is defective change it.

Check quenching box

and nozzle for scale,

descale if necessary.

yesno

no

yes

Fuse of I/O pcb or pcb

defective.

no

Remove all grids and containers

from interior cabinet, Install air baffle

correctly.

Start a CleanJet-program.

Program was finished completely?

(enough water is coming out of the

nozzle, fan motor reduces speed)

yes

Failure appeared because of

miss handling.

Inform customer of correct

handling.

CleanJet-Pump and corresponding

water supply lines

leak tight and pipes clean?

Eliminate leaks and/or dirt.

Ball valve leak tight?

no

Loading...

Loading...