MANUAL – REFLEX EZ-TRAC™ | 63

with the wedge down in the borehole. The diameter and threads of

the mule shoe sleeve should be exactly the same as the drill rods

being used. The mule shoe sleeve is provided in 0.6 m/2 ft sections.

When surveying relative to Magnetic Tool Face, six aluminium

extension rods and nine meters of non-magnetic drill rods are also

required.

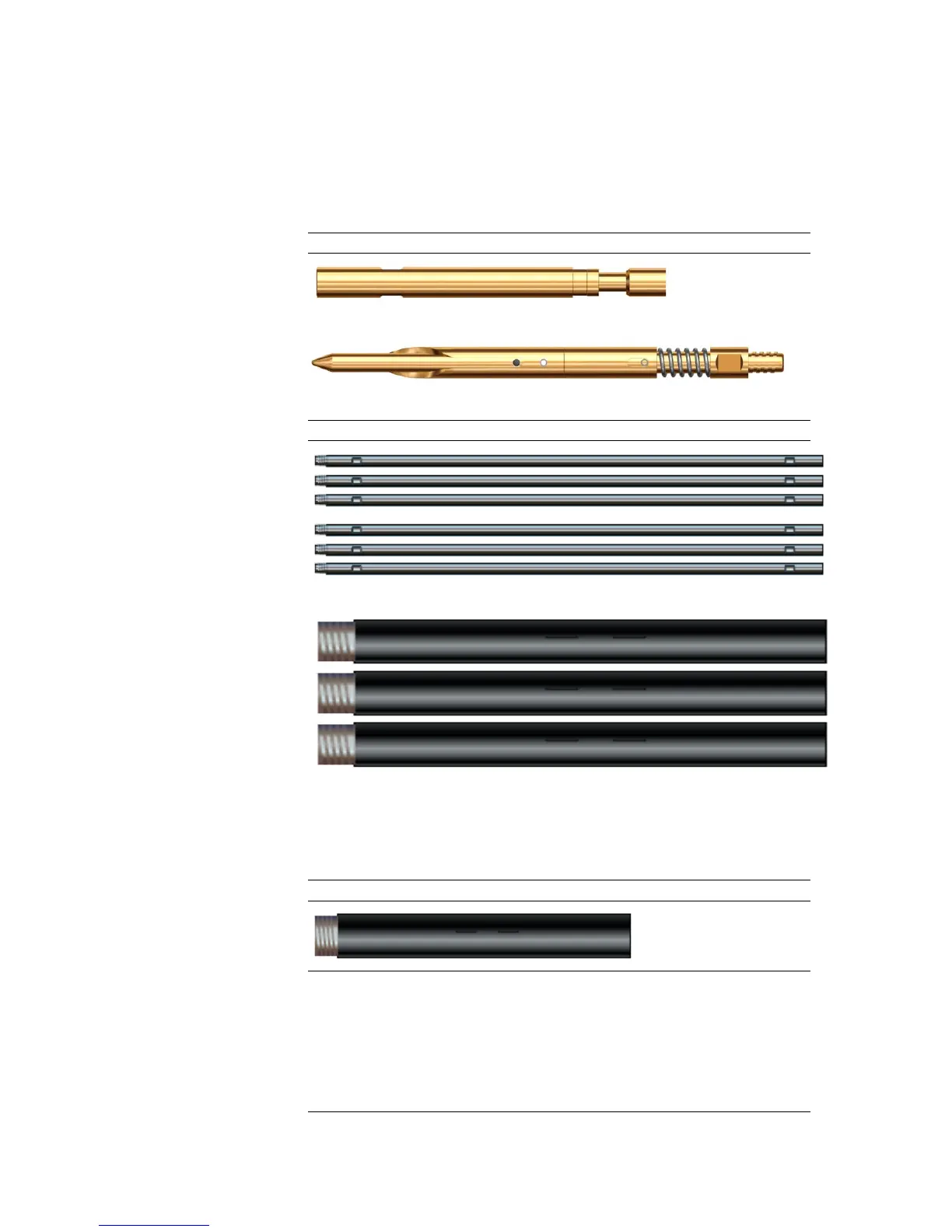

Figure 74 Orientation equipment

Orientation bull plug

Orientation mule shoe

Figure 75 Additional equipment for Magnetic Tool Face mode

6 aluminium extension rods

9 meters of non-magnetic drill rods

10.4.1 Mule shoe sleeve

The direction indicator (pin) on the mule shoe sleeve shall be aligned

with the kick direction of the wedge.

Figure 76 Mule shoe sleeve

Align mule shoe sleeve

1. Set out the wedge horizontally on the rod rack or the ground, with

its required kick direction pointing vertically upwards.

2. Thread the mule shoe sleeve onto the wedge.

3. The mule shoe sleeve is now ready for zeroing, as described in

the section Zeroing below.

Loading...

Loading...