19A-67

COOLING

Plenum chamber: Removal - Refitting

F9Q

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

a Remove:

-the engine undertray bolts,

-the engine undertray.

a Drain the cooling system (see 19A, Cooling, Coo-

ling circuit: Draining - Refilling, page 19A-17) .

a Remove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wi-

per arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under scuttle panel grille: Removal - Refitting)

(56A, Exterior equipment),

-the battery (see Battery : Removal - Refitting)

(80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the intercooler air inlet pipe (see 12B, Turbochar-

ging, Intercooler air inlet pipe: Removal - Refit-

ting, page 12B-41) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

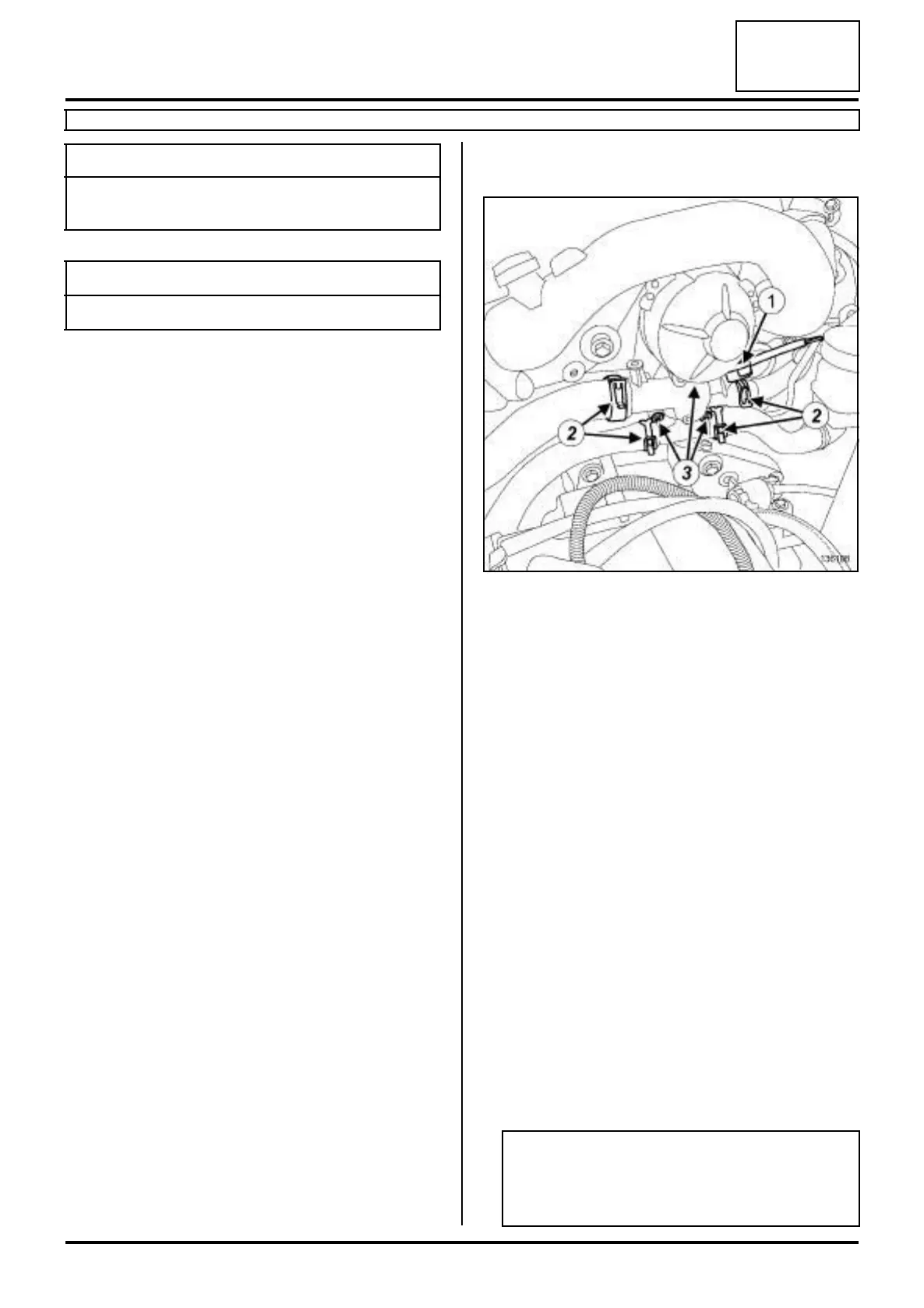

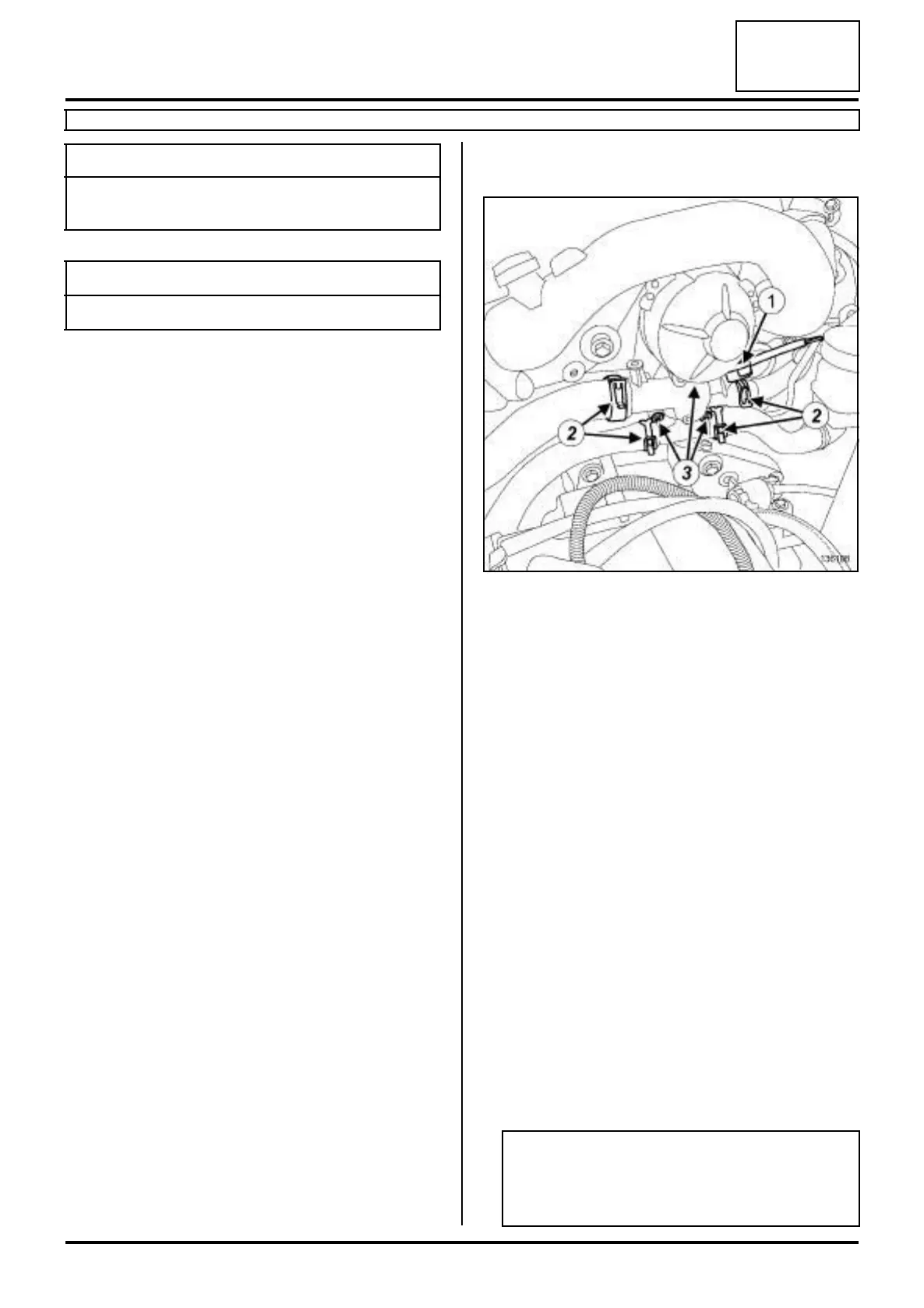

a Disconnect the coolant temperature sensor connec-

tor (1) .

a Separate the coolant outlet unit clips (2) using the

tool (Mot. 1448).

a Disconnect the coolant outlet unit hoses.

a Remove:

- the coolant outlet unit bolts (3) ,

- the coolant outlet unit,

- the coolant outlet unit seal.

REFITTING

I - REFITTING PREPARATION OPERATION

a parts always to be replaced: Cylinder head coo-

lant outlet unit seal (10,06,01,19).

a Use SURFACE CLEANER (see Vehicle: Parts

and ingredients for the repairwork) (04B, Consu-

mables - Products) to clean and degrease:

- the coolant outlet unit gasket face if needed to be

reused,

- the cylinder head joint face.

Essential special tooling

Mot. 1448 Long nose pliers for hose

clips.

Tightening torquesm

coolant outlet unit bolts 10 N.m

136198

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger marks).

Loading...

Loading...