Reference Manual

00809-0100-4360, Rev BA

August 2008

Rosemount 1151

4-8

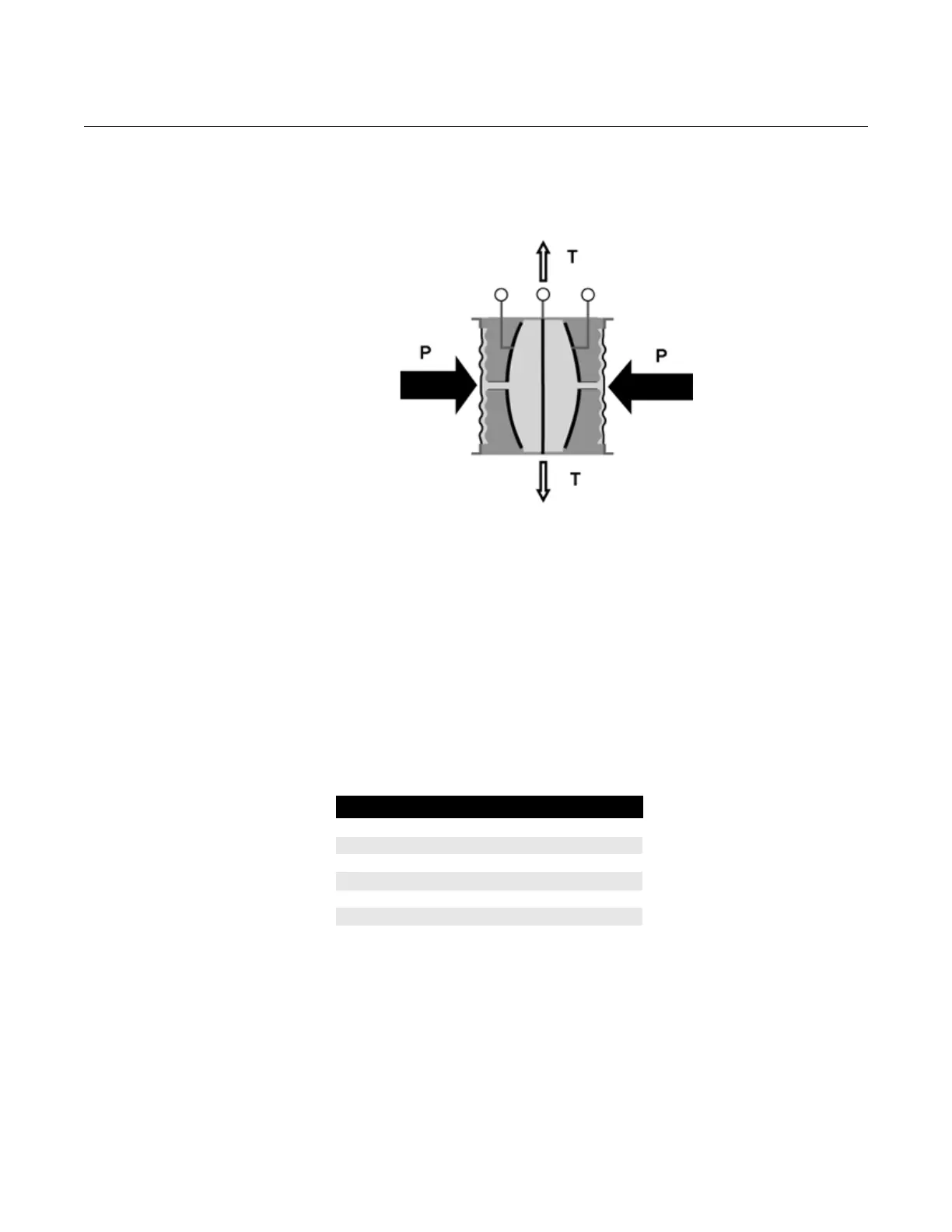

When high pressure is applied to both sides of the cell, a slight deformation

takes place, increasing tension in the sensing diaphragm. See Figure 4-5.

Figure 4-5. Static Pressure

Effect on the -Cell Sensor.

This increase in tension causes a reduction in transmitter output; as static

pressure increases, output for any given differential decreases. In other

words, as static pressure increases, a slightly higher differential pressure is

required to move the sensing diaphragm a given amount. This static pressure

effect is repeatable and linear, because it is within the realm governed by

Hooke's Law, which states that a body acted upon by an external force will

deform linearly, proportional to the stress, so long as a certain limit is not

exceeded.

High static pressure causes a systematic span shift in the transmitter.

Because static pressure always acts to reduce span and is linear, it is easy to

correct the effect during calibration by performing a sensor trim. Table 4-2

shows the amount of systematic span shift for Range Codes 3 through 8.

Table 4-2. Systematic Span

Shift

Correction for systematic error is made by simply calculating a correction

factor for the high trim and low trim and inputting this correction into the

transmitter.

To correct for systematic error due to static line pressure, use the following

formulas to determine a corrected value for Low Trim and High Trim.

Range Code 316L SST Alloy C-276

3 –1.75% –1.0%

4 –0.90%

(1)

(1) Applies also to Rosemount 1151HP.

–0.60%

5–0.80%

(1)

–0.70%

6 –1.50%

(1)

–1.45%

7–1.00%

(1)

–1.05%

8 –0.65% –0.65%

Loading...

Loading...