63

Reference Manual

00809-0100-4803, Rev GA

Configuration

September 2017

Configuration

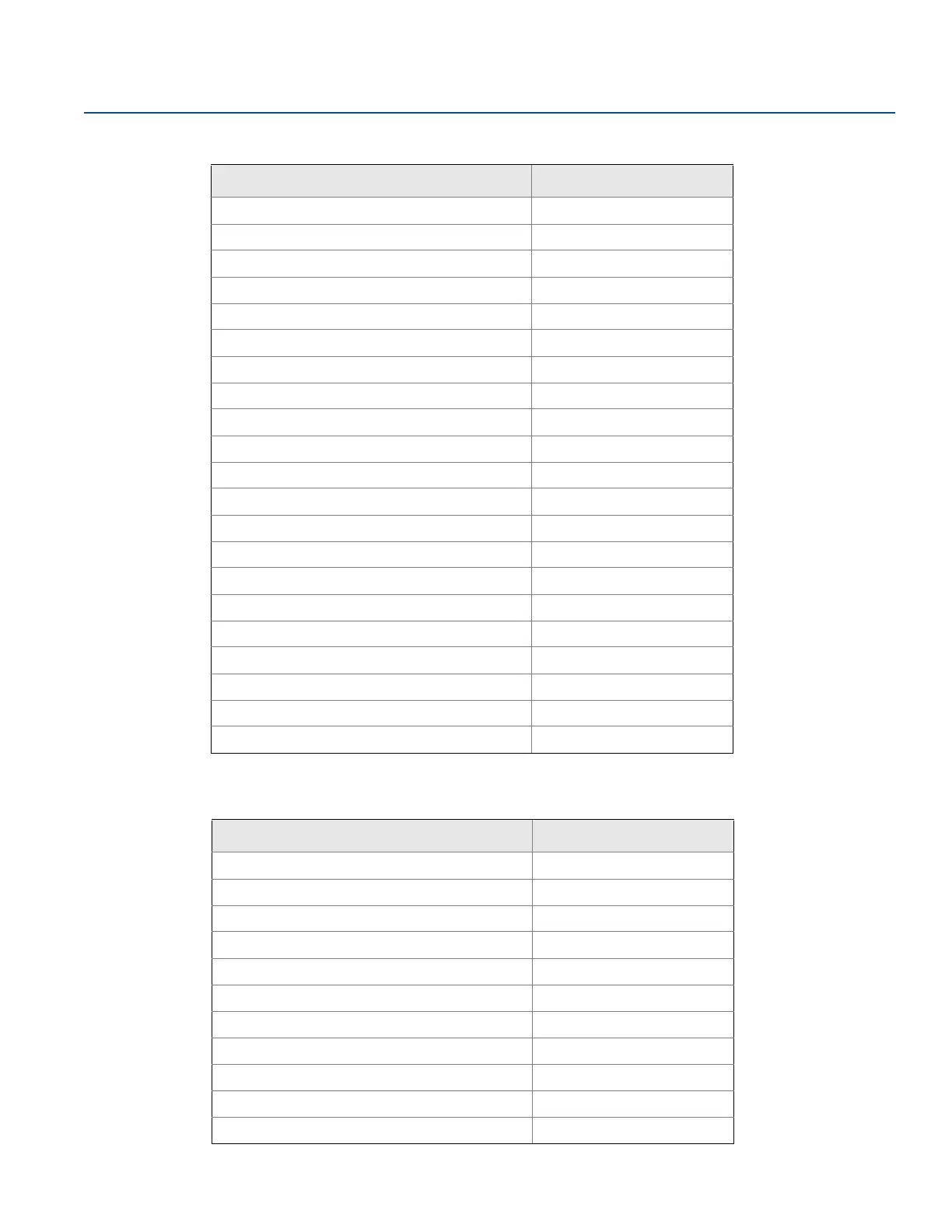

Module Temperature Reading and Status 1, 4, 2, 1, 8

Module Temperature Units 1, 3, 3, 8

Poll Address 1, 4, 3, 3, 1

Process Temperature Reading and Status 1, 4, 2, 1, 7

⻫

Process Temperature Sensor Mode 1, 4, 1, 6, 8

Process Temperature Sensor Trim Options 1, 2, 5, 5

Process Temperature Unit 1, 3, 3, 7

⻫

Ranging the Analog Output 1, 2, 5, 1

Recall Factory Trim Settings 1, 2, 5, 2, 3

Sensor Information 1, 4, 4, 2

⻫

Static Pressure Sensor Lower Trim (AP Sensor) 1, 2, 5, 4, 2

Static Pressure Sensor Trim Options 1, 2, 5, 4

⻫

Static Pressure Sensor Zero Trim (GP Sensor) 1, 2, 5, 4, 1

⻫

Status 1, 2, 1

⻫

Ta g 1, 3, 1

Test Flow Calculation 1, 2, 3

Totalizer Configuration 1, 4, 1, 3

Totalizer Reading and Status 1, 4, 2, 1, 3

Totalizer Units 1, 3, 3, 3

Variable Mapping 1, 4, 3, 4

Write Protect 1, 3, 5, 4

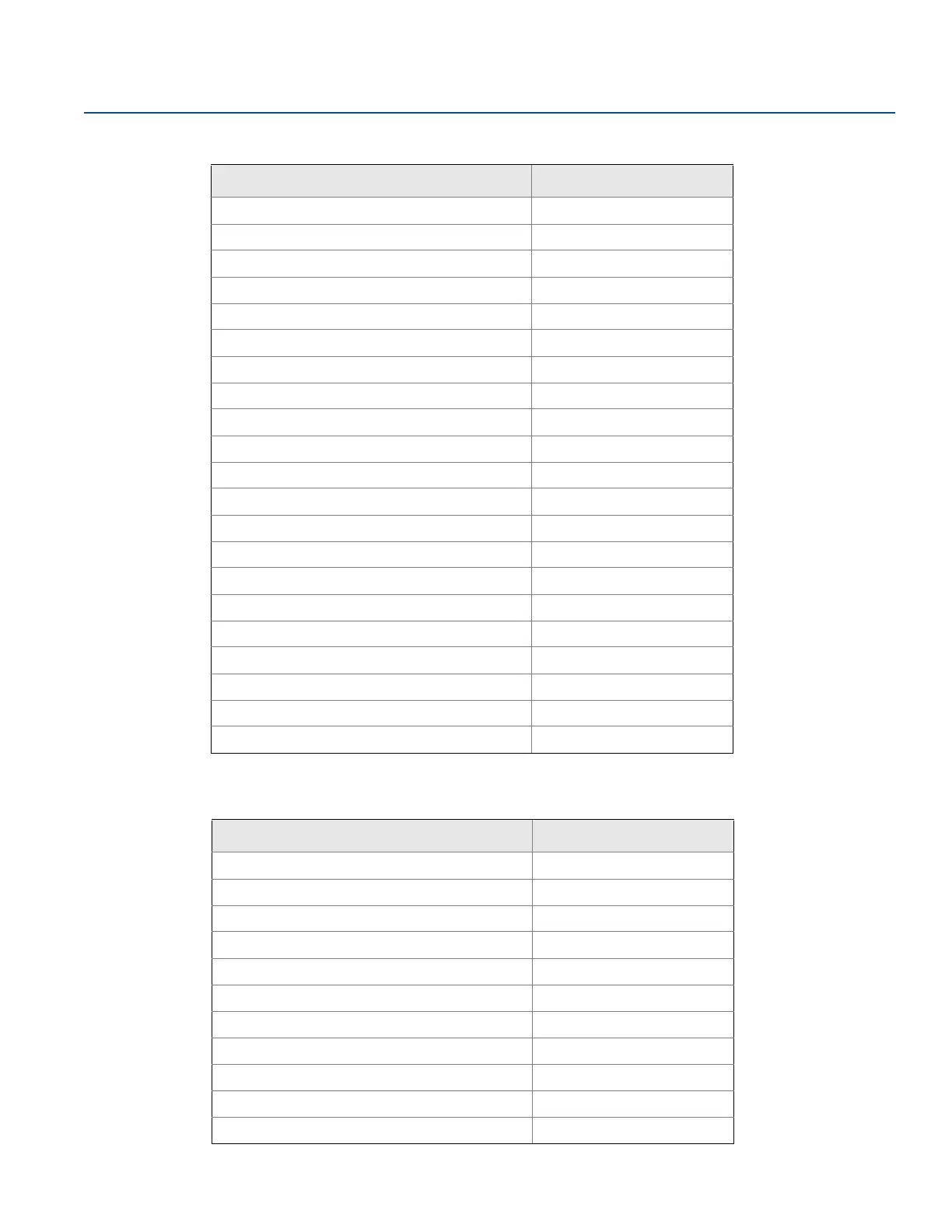

Table 2-14. Fast Keys for Direct Process Variable Measurement

Function Fast Key sequence

Absolute Pressure Reading and Status 1, 4, 2, 1, 2

Absolute Pressure Sensor Limits 1, 4, 1, 2, 8

⻫

Absolute Pressure Units 1, 3, 3, 2

Alarm and Saturation Level Configuration 1, 4, 2, 6, 6

Alarm and Saturation Levels 1, 4, 2, 6

Analog Output Trim Options 1, 2, 4, 2

Burst Mode Setup 1, 4, 3, 3, 3

Burst Mode Options 1, 4, 3, 3, 4

Callendar-van Dusen Sensor Matching 1, 2, 4, 5, 4

Damping 1, 3, 7

Diaphragm Seals Information 1, 4, 4, 4

Table 2-13. Fast Keys for Fully Compensated Mass and Energy Flow Output

Function Fast Key sequence

Loading...

Loading...